Nursery stock surrounding type automatic pruning component

A wrap-around, seedling technology, applied in electric pruning saws, cutting tools, cutting equipment, etc., can solve the problems of endangering the life safety of operators, low pruning efficiency, high labor intensity, etc., and achieves ingenious structure, convenient operation and use. The effect of a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

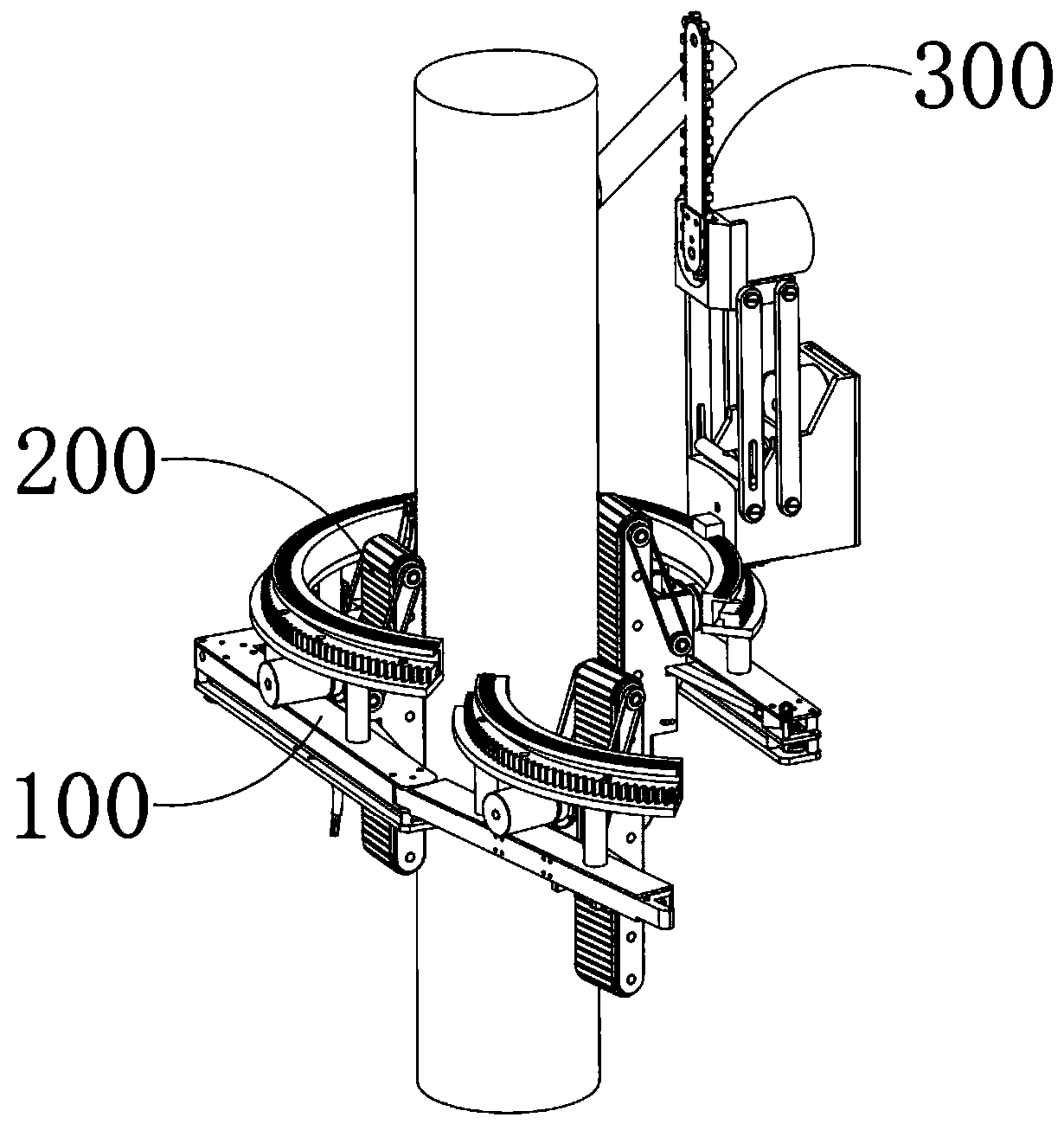

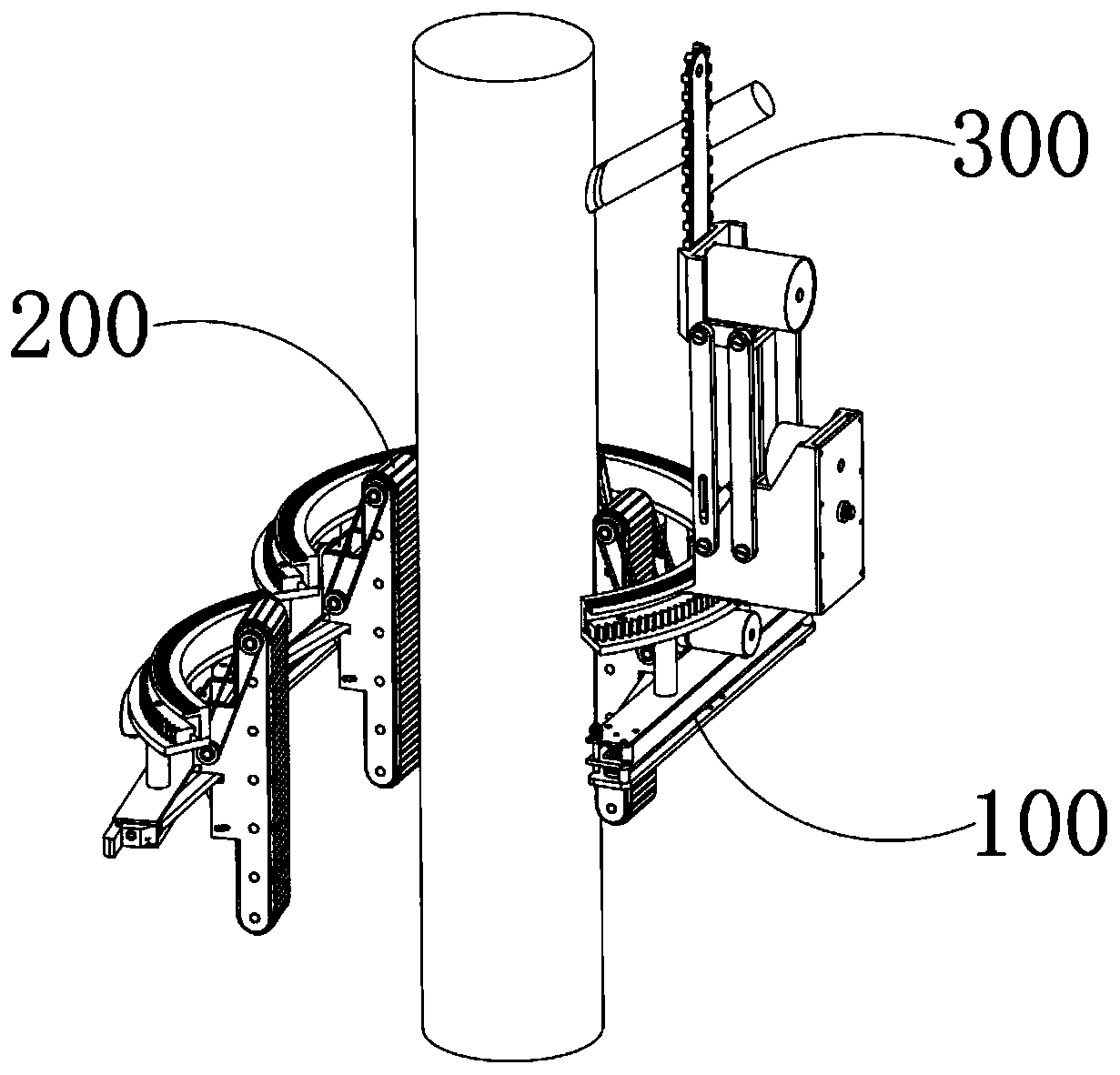

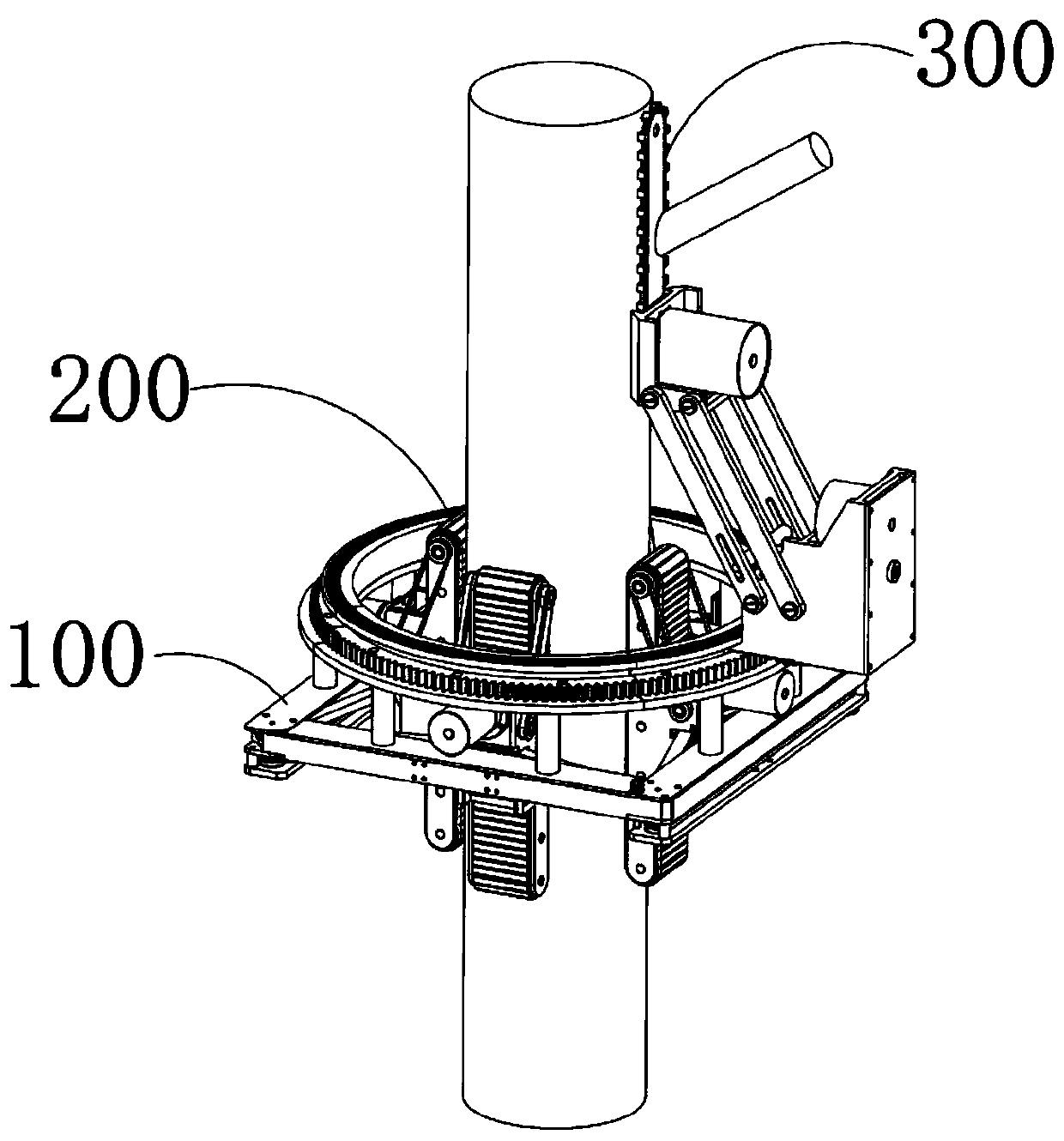

[0042] see Figure 1-24, a crawler-type automatic climbing tree trimmer, which includes an extension support part 100, four climbing parts 200 and a pruning part 300, the extension support part 100 is arranged in a square structure, and the climbing part 200 is movably arranged on the extension support part 100 and are symmetrically arranged in pairs. The pruning parts 300 are movably arranged on the upper end surface of the extension support part 100. The extension support part 100 can be sleeved on the trunk of the tree and gradually unfolded to drive the climbing part 200 to tightly contact the trunk of the tree. The part 200 can climb vertically upward along the trunk of the tree and drive the stretch support part 100 to move upwards synchronously with the pruning part 300. The pruning part 300 includes a surrounding drive mechanism 310, a translational drive mechanism 320 and a cutting mechanism 330. It can drive the translation drive mechanism 320 and the cutting mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com