Temperature-controllable and humidity-controllable air-curing room special for cigar tobacco and air-curing method

A technology for cigar tobacco leaves and drying room, which is applied in the field of special drying room and drying room for cigar and tobacco leaves, can solve the problems of rough organizational structure, large environmental impact, poor elasticity, etc., so as to improve wall structure, overcome high cost and reduce rotten Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

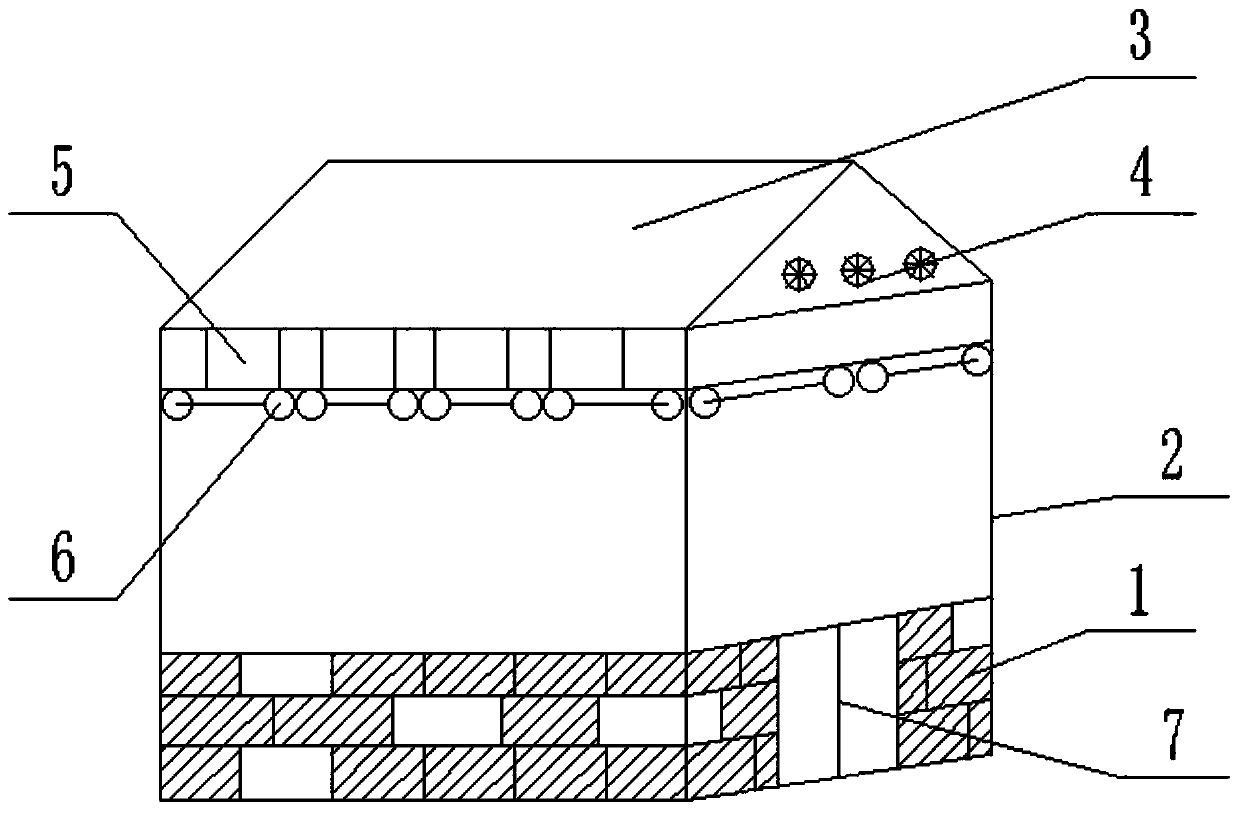

[0030] Such as figure 1 As shown, the present embodiment provides a temperature-controllable and humidity-controllable airing room for cigars and tobacco leaves, comprising a wall 1, a column 2, a roof 3, a beam, a humidifying device, a heating device, a roller shutter 6, a temperature and humidity sensor, Control panel, drying rack and drying rod. Body of wall 1 forms a rectangle, length and width are 23m and 11m respectively, body of wall 1 has air vent and opening and closing door 7, and air vent is integrally formed when building body of wall 1, can block when not in use. There are four columns 2, the lower ends of the four columns 2 are fixed to the four corners of the wall 1, the upper ends of the columns 2 are fixed to the lower end of the roof 3, the height of the wall 1 is 1.5m, from the lower end of the wall 1 to the upper end of the roof 3 The height is 8.6m. The lower end of the roof 3 is rectangular, the lower end of the roof 3 has the same shape and size as the...

Embodiment 2

[0047] This embodiment is an improvement made on the basis of Embodiment 1. The improvement is that the length and width of the wall body 1 are 23.5m and 11.5m respectively, and the height of the second floor of the tobacco drying rack from the bottom to the ground is 2.2m, located on the highest floor and the height of 3 eaves from the roof is 1.45m.

[0048] Tobacco rod weaving of cigar leaves: the airing rod is 2.20m, and the leaves are back to back. There are 52 tobacco leaves on each rod, and the distance between each rod is 22cm.

[0049] Withering period: control the ventilation in the drying room, utilize the wall body 1 and exhaust fan 4, control the ambient temperature around the tobacco leaves at 22°C, and the relative humidity at 85%, keep for 2 days, so that the leaves change from an upright state to a withered state.

[0050] Yellowing period: Use heating device and humidifying device to control the ambient temperature of tobacco leaves at 30°C and relative humid...

Embodiment 3

[0054] This embodiment is an improvement made on the basis of the first embodiment. The improvement is that the length and width of the wall body 1 are 24m and 12m respectively. The second floor of the tobacco drying rack from bottom to top is 2.5m from the ground, and the distance from the top floor to the roof is 1.5m.

[0055] Tobacco rod weaving for cigar leaves: the drying rod is 2.25m long, and the leaves are back-to-back. There are 55 tobacco leaves on each rod, and the distance between each rod is 25cm.

[0056] Withering period: control the ventilation in the drying room, utilize the wall body 1 and exhaust fan 4, control the ambient temperature around the tobacco leaves at 24°C, and the relative humidity at 90%, it takes 2 days to make the leaves change from an upright state to a withered state.

[0057] Yellowing period: Use heating device and humidifying device to control the ambient temperature of tobacco leaves at 32°C and relative humidity at 90%, and the entire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com