Casting roll cooling device for continuous cast-rolling of aluminum sheets

A technology of cooling device and casting roll, applied in the direction of roll, metal rolling, metal rolling, etc., can solve the problem of poor cooling effect of cooling device, and achieve the effect of improving cooling efficiency and expanding contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

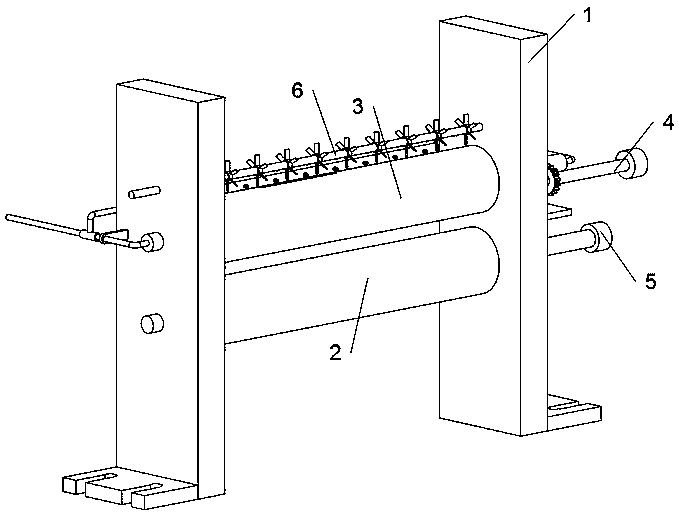

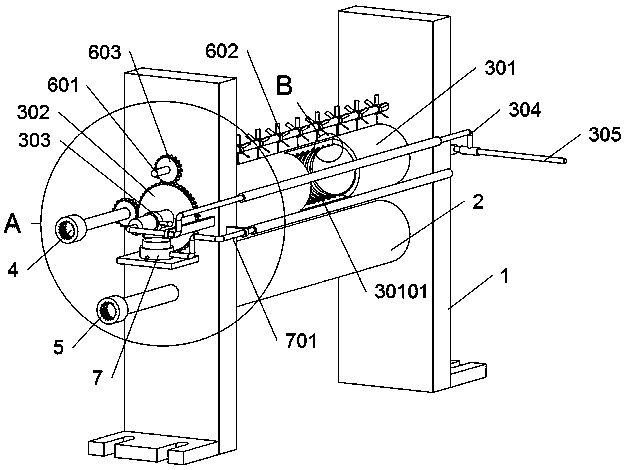

[0026] as attached figure 1 To attach Figure 5 Shown:

[0027] The invention provides a casting roll cooling device for continuous casting and rolling of aluminum plates, which includes a frame body 1; a lower die-casting roll 2 and an upper die-casting roll structure 3 are rotatably connected to the frame body 1, and an upper drive shaft 4 is rotatably connected to the frame body 1 , and the upper drive shaft 4 is meshed with the upper die-casting roll structure 3 for transmission; the lower die-casting roll 2 is equipped with a lower drive shaft 5; the frame body 1 is rotatably connected with a cooling structure 6, and the frame body 1 is equipped with an elastic cylinder 7.

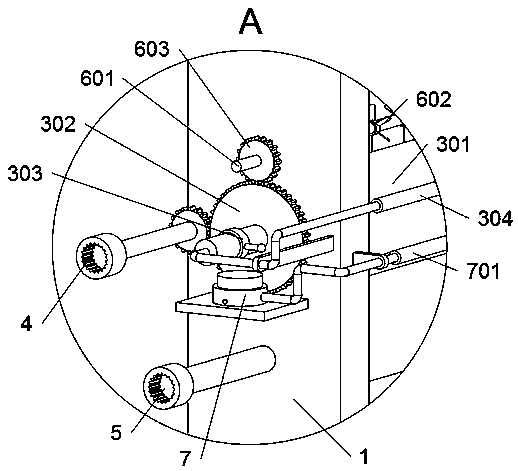

[0028] Reference as image 3 , the upper die-casting roller structure 3 includes a roller main body 301, a gear A302, a toggle arm 303, a spray pipe 304 and a water inlet pipe 305, the roller main body 301 is equipped with a gear A302 and a toggle arm 303, and the roller main body 301 is hollow Str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com