Mathematical model calculation device and control device for rolling line

A mathematical model and computing device technology, which is applied to rolling mill control devices, complex mathematical operations, program control, etc., can solve problems such as the reduction of mathematical model prediction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

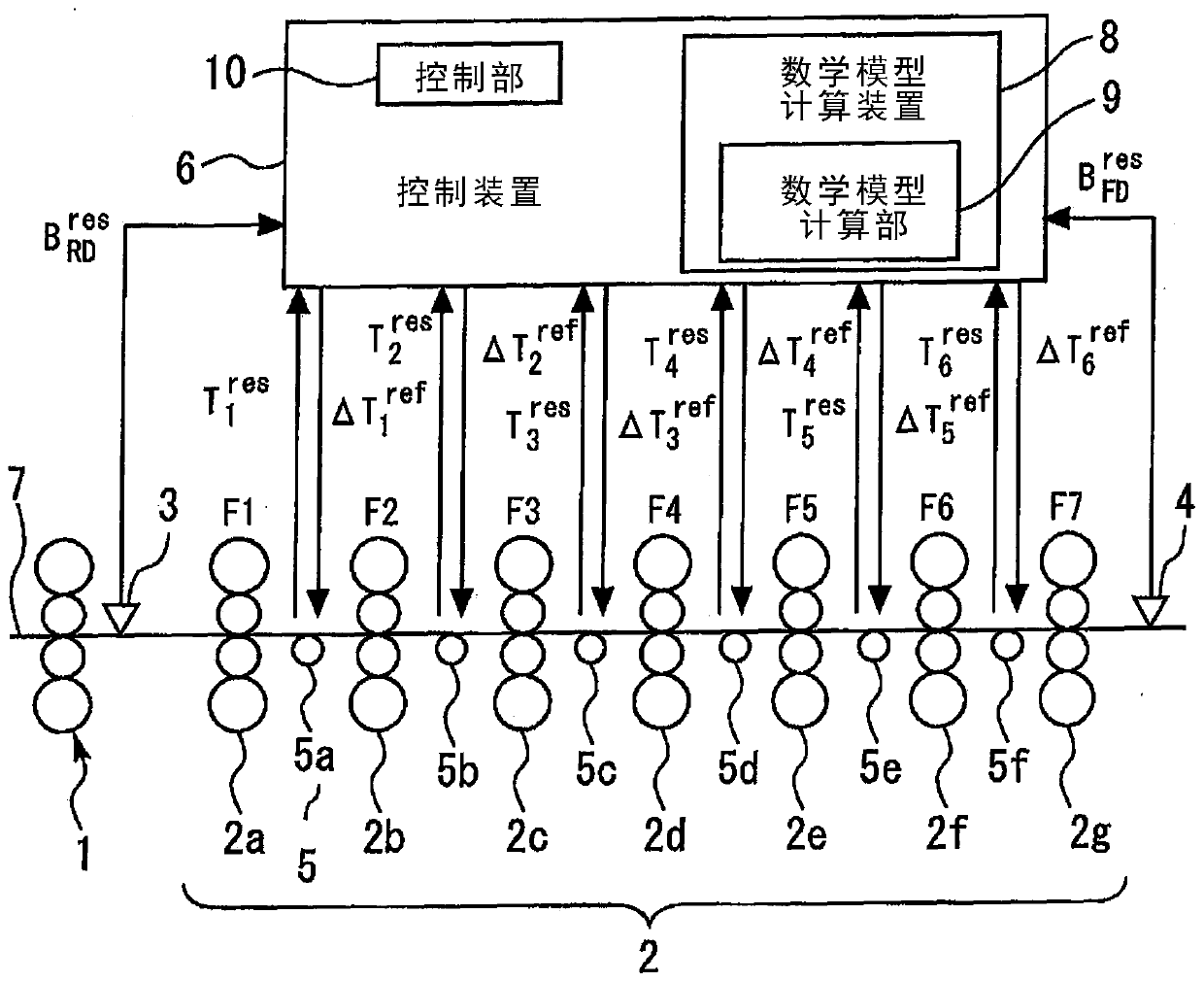

[0027] figure 1 It is a configuration diagram of a hot rolling line to which the mathematical model calculation device of the rolling line in Embodiment 1 is applied.

[0028] Such as figure 1 As shown, the hot rolling production line includes a roughing mill 1 , a finishing mill 2 , a roughing mill exit side strip width gauge 3 , a finishing mill exit side strip width gauge 4 , a looper device 5 and a control device 6 .

[0029] The rough rolling mill 1 is installed on the exit side of a heating furnace not shown. The finish rolling mill 2 is installed on the output side of the rough rolling mill 1 . The finishing mill 2 includes a plurality of stands. Multiple racks are arranged horizontally. For example, the plurality of racks is constituted by a rack 2a, a rack 2b, a rack 2c, a rack 2d, a rack 2e, a rack 2f, and a rack 2g. The strip width gauge 3 on the output side of the rough rolling mill is installed on the output side of the rough rolling mill 1 and the input side...

Embodiment approach 2

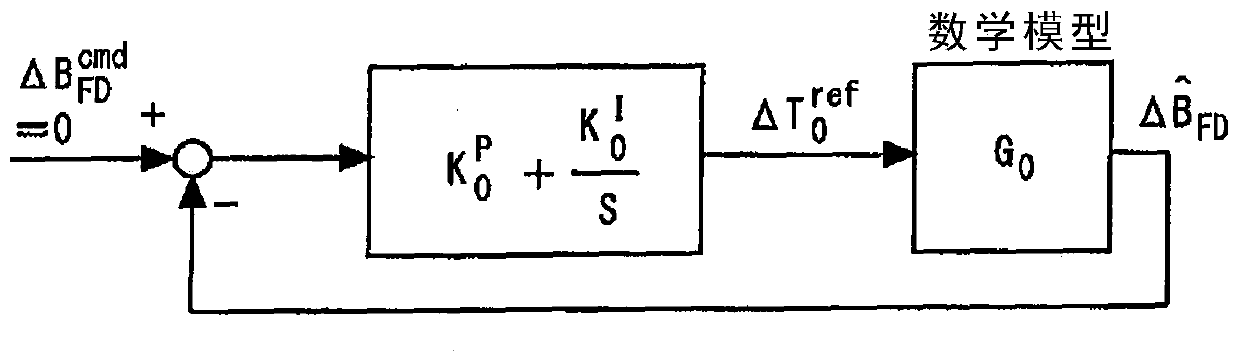

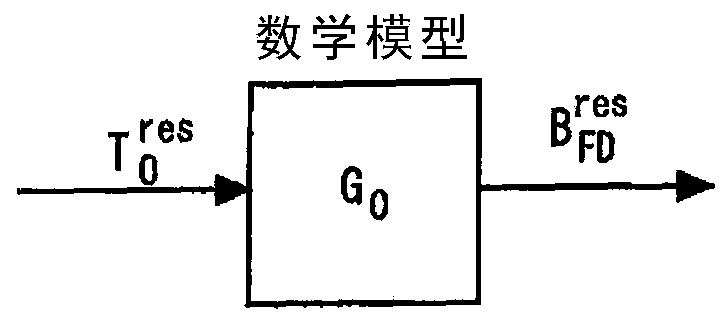

[0114] Figure 11 It is a block diagram explaining the control of the rolling line to which the mathematical model calculating device of the rolling line in Embodiment 2 is applied. In addition, the same code|symbol is attached|subjected to the part which is the same as or equivalent to the part of Embodiment 1. As shown in FIG. The description of this part is omitted.

[0115] In Embodiment 2, the control device 6 includes a Smith compensator 11 . The Smith compensator 11 online will change the reference value (command value) for the tension between the racks Negative feedback to the PI controller. In addition, the control device 6 also uploads online the predicted value of the strip width at the exit side of the finishing mill after the time-consuming delay caused by the transmission delay from the strip width meter 4 at the exit side of the finishing mill has passed. Also negative feedback to the PI controller. At this time, if the predicted value of the output side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com