Magnetic medium assisted plate punching forming device and method

A magnetic medium and plate technology, applied in the field of plate blanking, can solve the problems of unbalanced force on the punch, poor cross-section quality, and excessive burr, so as to enhance the ability to resist deformation, eliminate the gap problem, and make a tight arrangement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

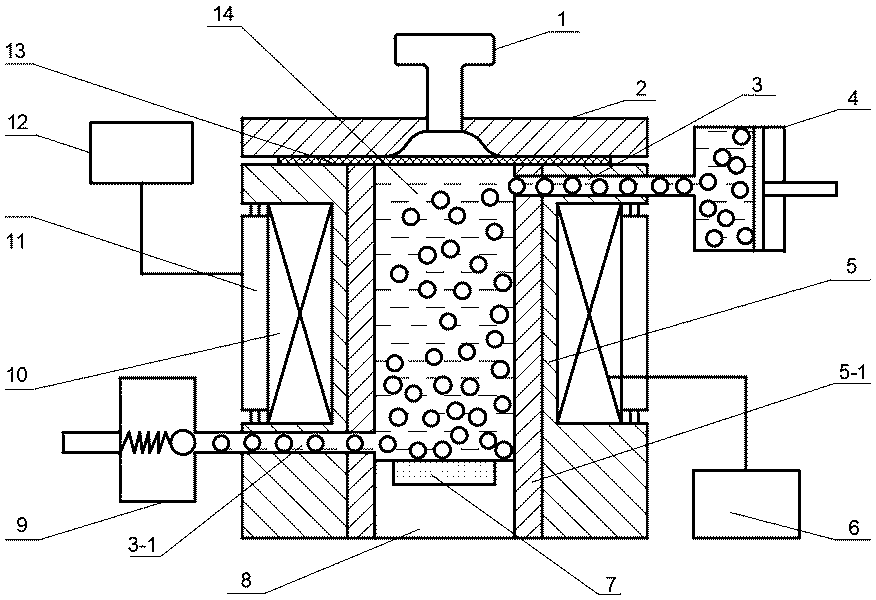

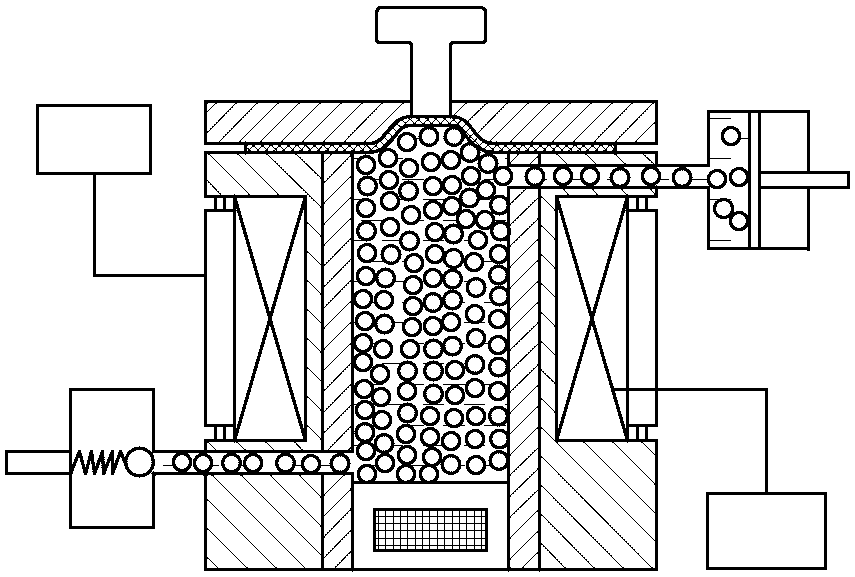

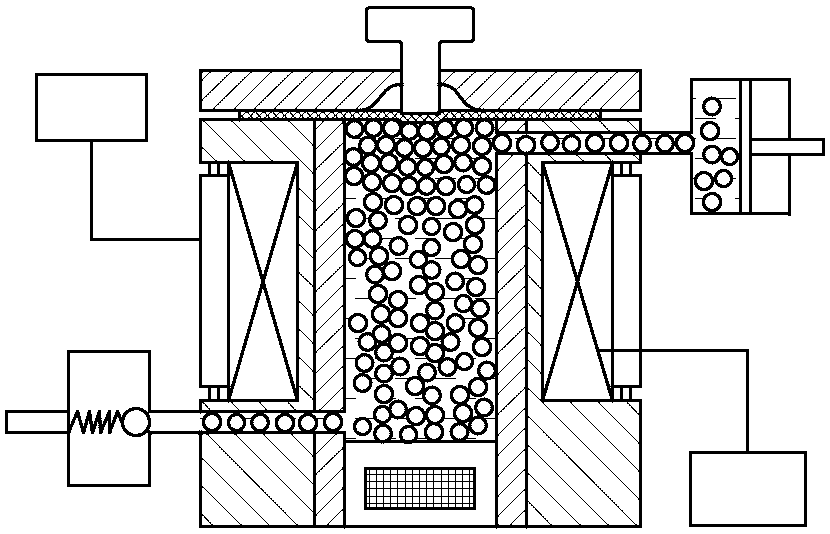

[0024] Specific implementation mode one: combine figure 1 Describe this embodiment, this embodiment includes a punch 1, a blank holder 2, a liquid channel input end 3, a liquid channel output end 3-1, a plunger cylinder 4, a die 5, a liquid storage chamber 5-1, a magnetic control Unit 6, pressure sensor 7, sealing block 8, pressure relief valve 9, coil 10, cooling device 11, cooling control unit 12, slab 13, magnetic medium 14. Firstly, the plunger cylinder 4 injects magnetic media 14 with different particle volume fractions, in which the base liquid accounts for 10%-35%, the magnetizable particles account for 40%-80%, and the stabilizer accounts for 1-5%. The slab 13 is placed on the upper end surface of the die 5, the blank holder 2 and the die 5 are aligned up and down, a part of the space is left in the blank holder 2, and guide holes are set, and the punch 1 and the blank holder 2 fit in a small gap . The coil 10 is embedded in the die 5 , and is controlled by the magne...

specific Embodiment approach 2

[0025] Specific implementation mode two: combination figure 1 To illustrate this embodiment, this embodiment is the injection of magnetic media with different particle volume fractions from the plunger cylinder in Step 1, wherein the base liquid accounts for 45%, the magnetized particles account for 50%, and the stabilizer accounts for 5%. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0026] Specific implementation mode three: combination figure 1 This embodiment is described. In the first step, the plunger cylinder injects magnetic media with different particle volume fractions, wherein the base liquid accounts for 24%, the magnetized particles account for 70%, and the stabilizer accounts for 6%. Other steps are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com