Manual self-punching riveting rivet feeding tool

A riveting stud and tooling technology is applied in the field of body manufacturing technology, which can solve the problems of low manufacturing process safety, unfavorable trial-produced body manufacturing process, operator injury, etc., and achieves reduction of manual injury accidents, simple structure and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

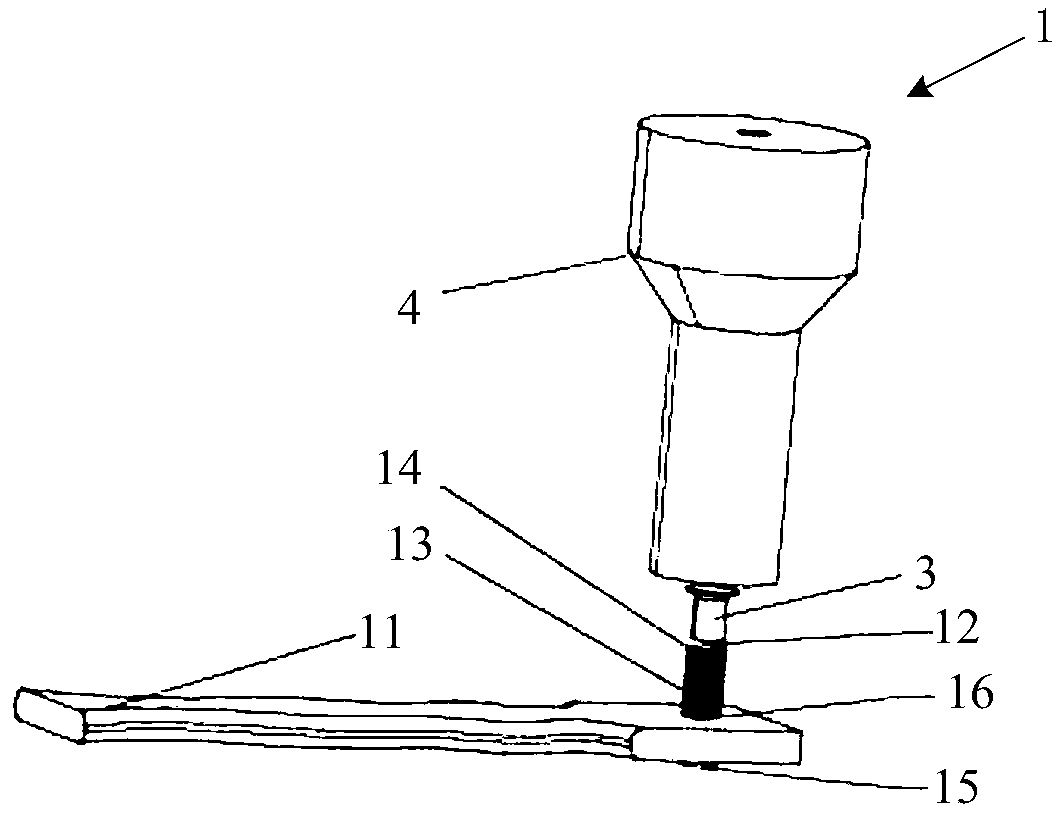

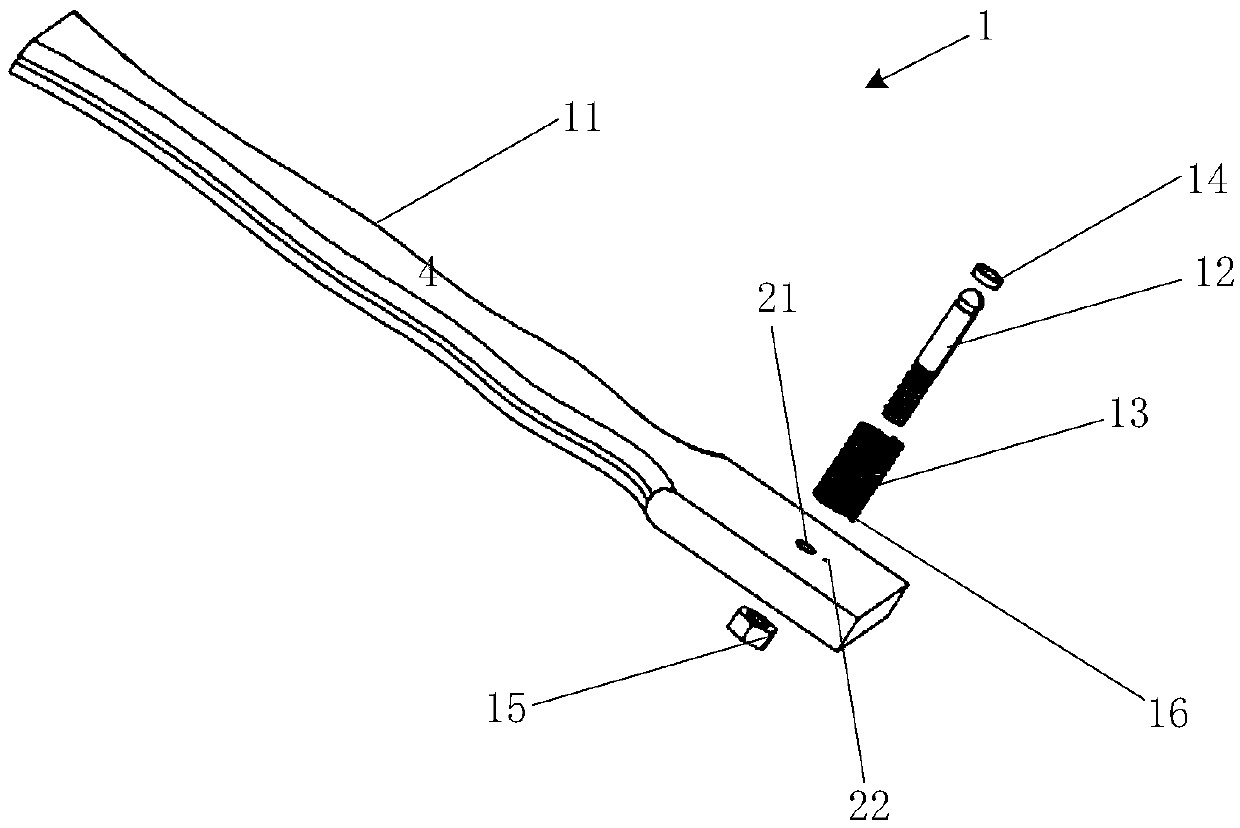

[0031] This embodiment provides an artificial self-piercing riveting tool, and the manual self-piercing riveting tool includes:

[0032] handle part;

[0033] at least one restricting part installed on the non-hand-held end of the handle part;

[0034] an elastic sleeve, sleeved on the restricting part, and fixed on the handle part;

[0035] The operator inserts the hole at the bottom of the rivet into the restricting part, aligns the tooling with the rivet with the rivet nose, and pushes it into the rivet nose, then presses the elastic sleeve tightly; when the operator loosens the tooling, The pushing force is canceled, and under the restoring force of the elastic sleeve, the frock is pushed out of the riveting nose.

[0036] The manual self-piercing riveting tool provided by this embodiment will be described in detail below with reference to the drawings. see figure 1 and figure 2 , which are respectively shown as a top view and an explosion photo of the artificial sel...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap