Flywheel feeding type gravity adaptive bolt cleaning device

A cleaning device and adaptable technology, applied in the field of machinery, can solve the problems of easy rusting, scrapped bolts, and cleaning agents containing toxic and harmful substances, and achieve the effect of preventing rusting, protecting bolts, and ensuring cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

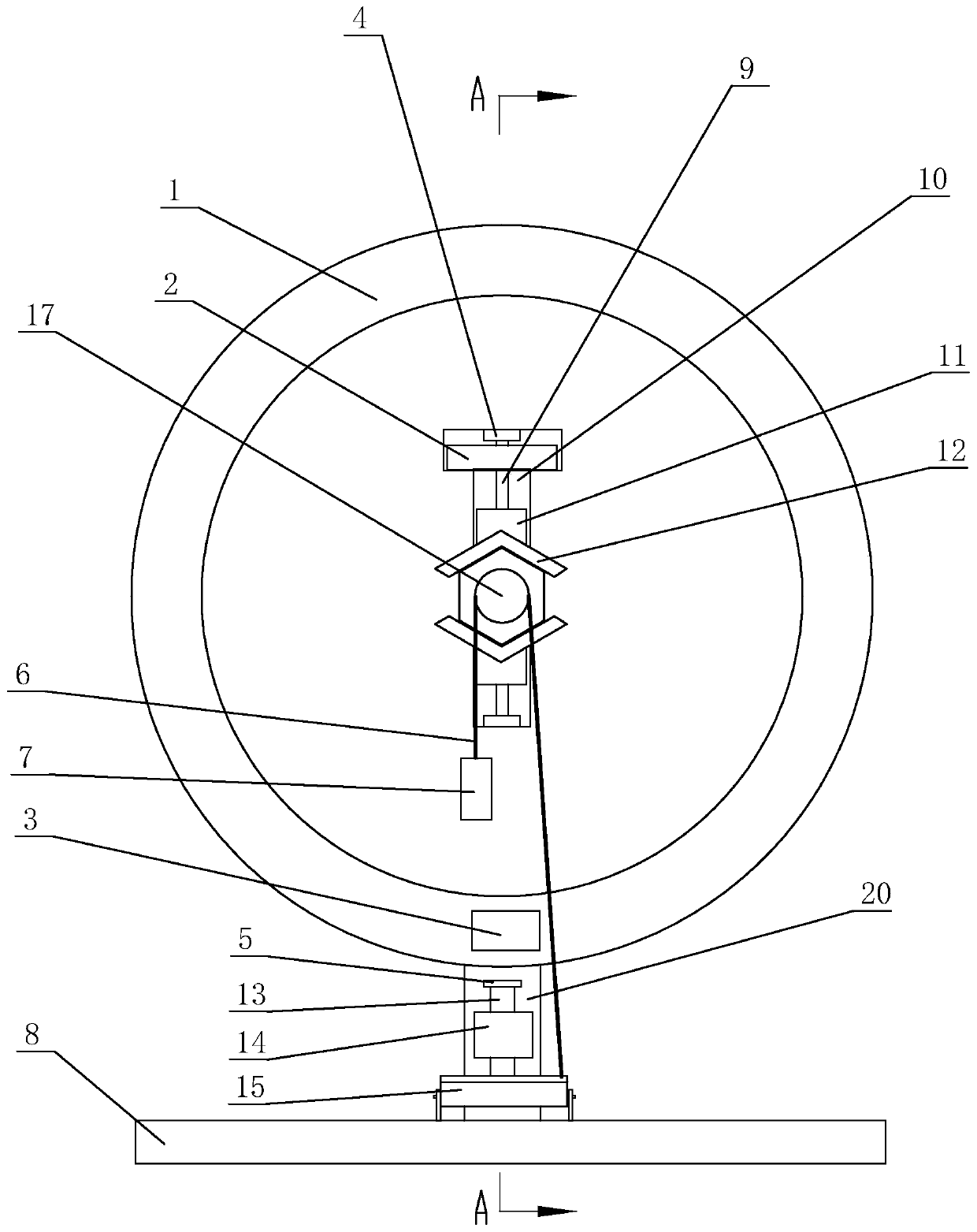

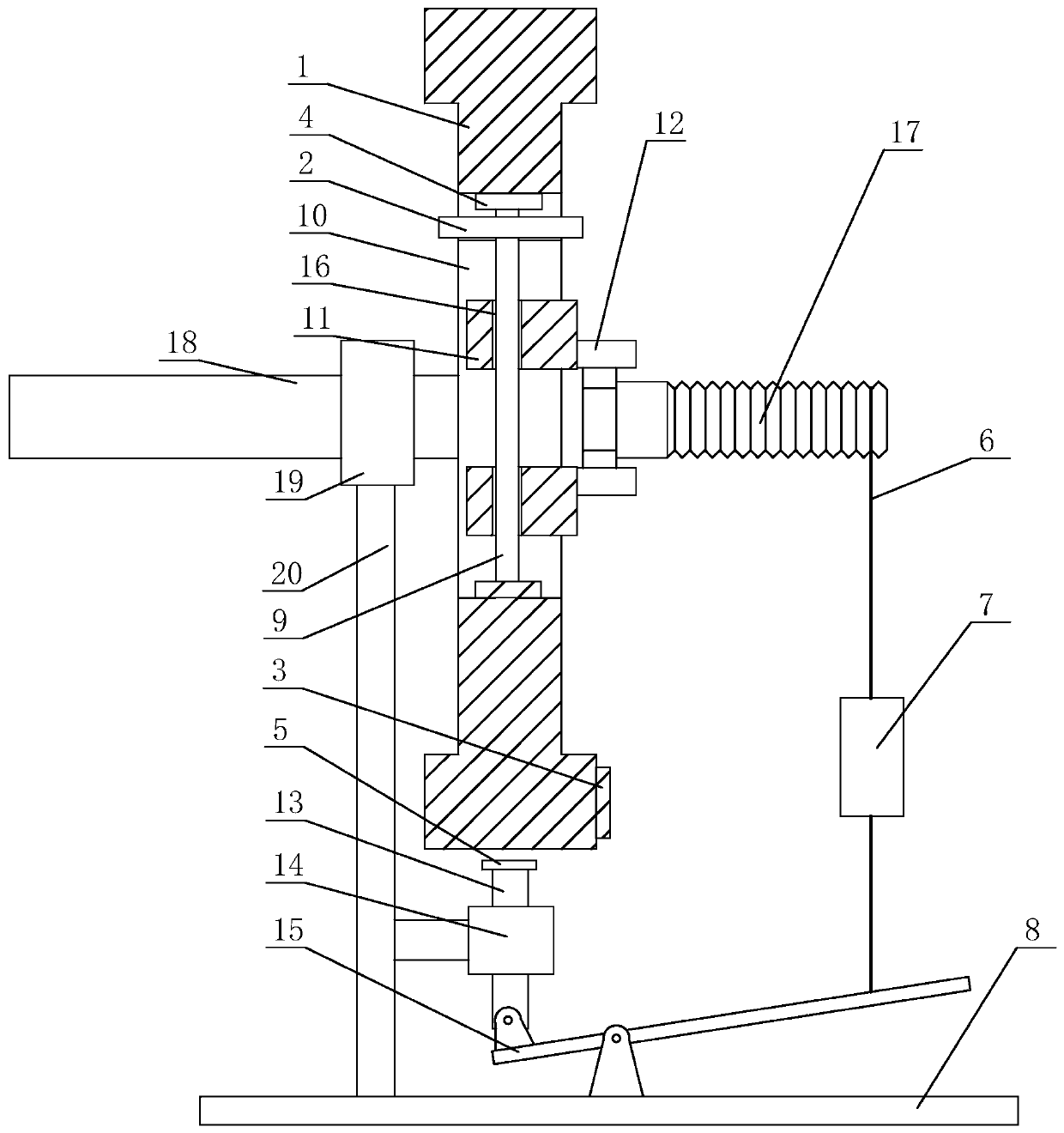

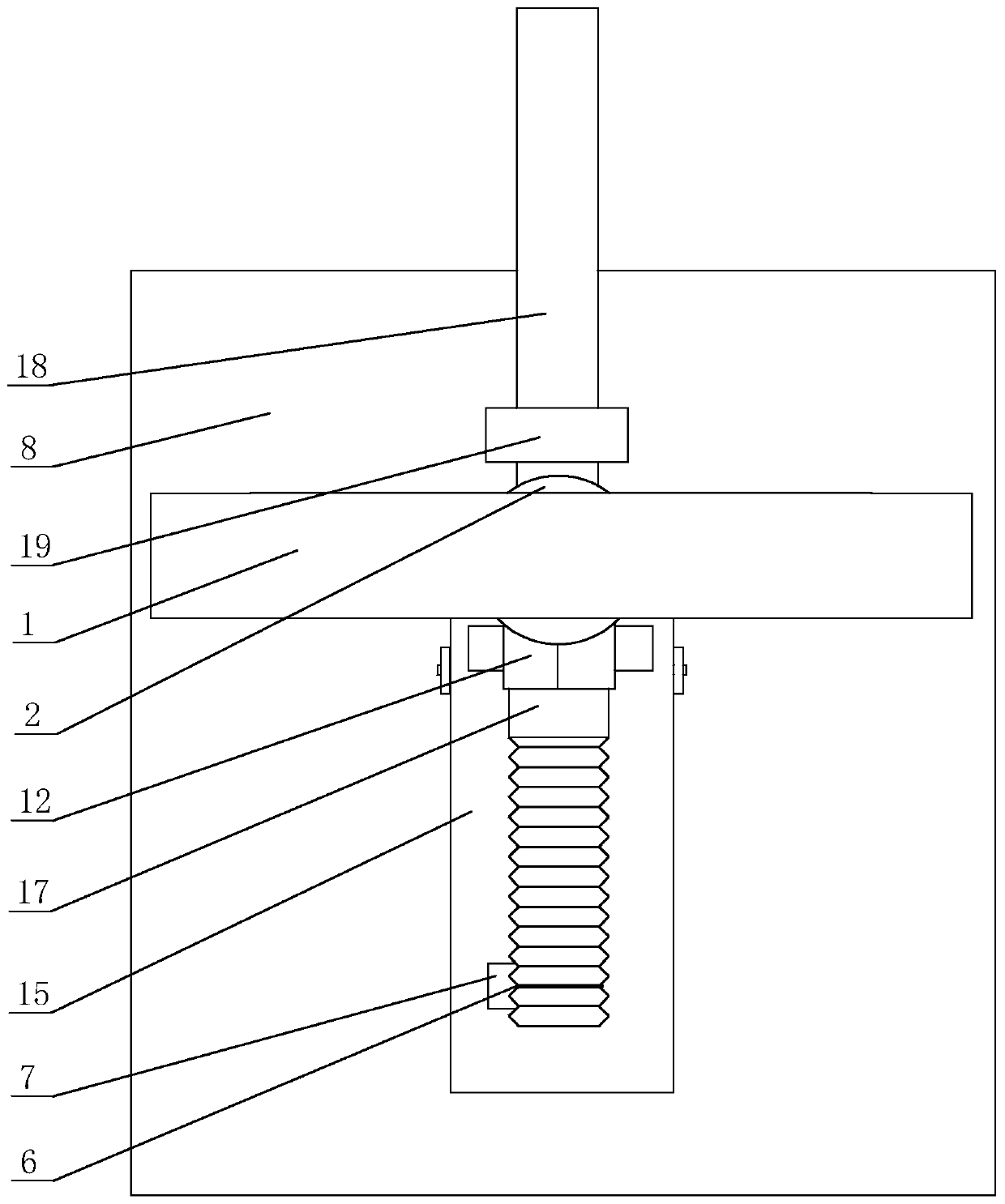

[0019] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

[0020] Such as Figure 1-Figure 3 As shown, the flywheel feeding type gravity-adaptive bolt cleaning device of the present invention includes a base 8, a vertically fixed column 20 on the base 8, a fixed nut 19 at the upper end of the column 20, and a feed screw 18 in the nut 19, and a feed screw 18 The flywheel 1 is coaxially fixed at the inner end, and a fixing device is arranged on the flywheel 1. The fixing device vertically fixes the bolt 17 at the center of the flywheel 1, the thin rope 6 is fixed on the base 8, the iron block 7 is fixed at the end of the thin rope 6, and the inside of the flywheel 1 Fixed magnet 3 on the end face, iron block 7 naturally droops after string 6 walks around bolt 17.

[0021] Principle and process:

[0022] When working, the bolt 17 is fixed at the center of the flywheel 1, and then the flywheel 1 is rotated forcefully. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com