Door panel and manufacturing process thereof

A production process and door panel technology, which is applied in the direction of manufacturing tools, door leaves, wood processing appliances, etc., can solve the problems of weak connection between the core panel and the door frame, appearance impact, hidden dangers in the use of users, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

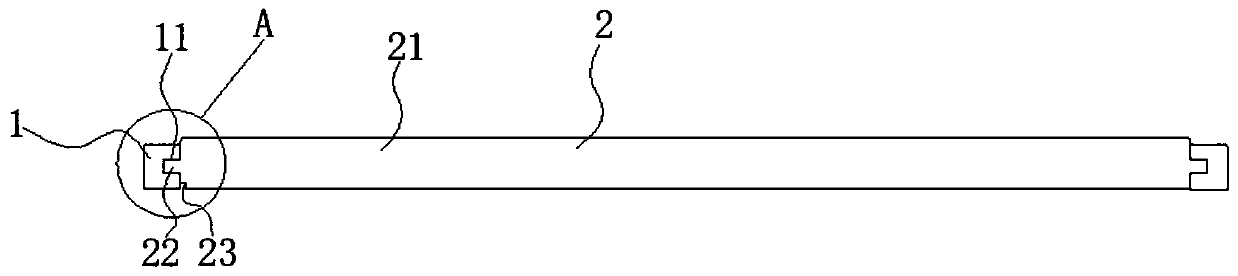

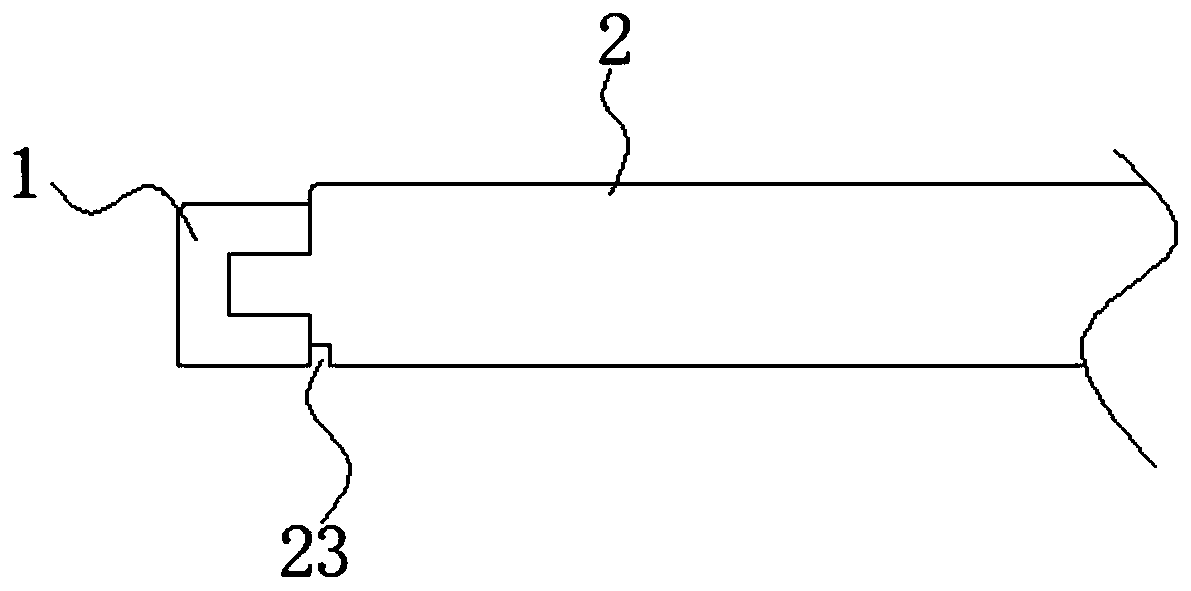

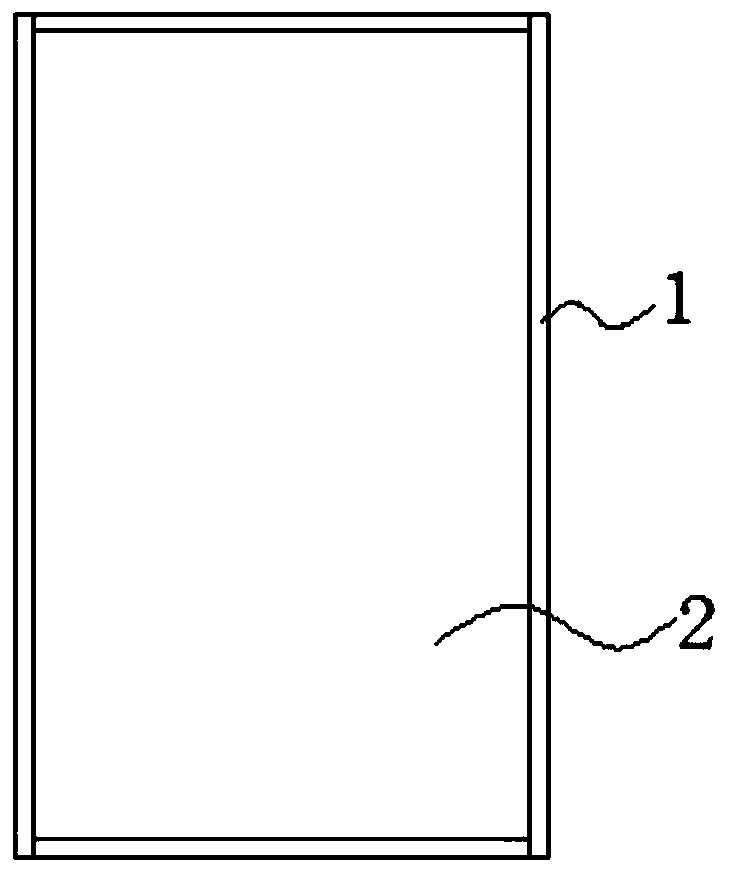

Image

Examples

Embodiment 2

[0038] See attached Figure 4 It shows a manufacturing process of a door panel of the present invention, which is applied to a door panel described in Embodiment 1, including the following steps: (1) blanking the core panel S1; (2) selecting materials for the door frame and making a shape S2; (3) Frame the core board and door frame and polish S3; (4) paste masking paper S4 on the door frame; (5) process S5 on the core board; (6) tear off the masking paper of the door frame, core Sticking masking paper on the board S6; (7) processing the door frame S7; (8) tearing off the masking paper on the core board S8. When processing the core board, paste masking paper on the door frame; when processing the door frame, paste masking paper on the core board. The two are processed separately and do not affect each other. It can be processed separately according to the different material properties of the door frame and the core board, so that the door frame and the core board can not only...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com