Vessel of the OBO or bulk carrier type

A technology for bulk cargo ships and ships, which is applied in the direction of bulk cargo, ship construction, ship parts, etc., and can solve problems such as leakage and shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

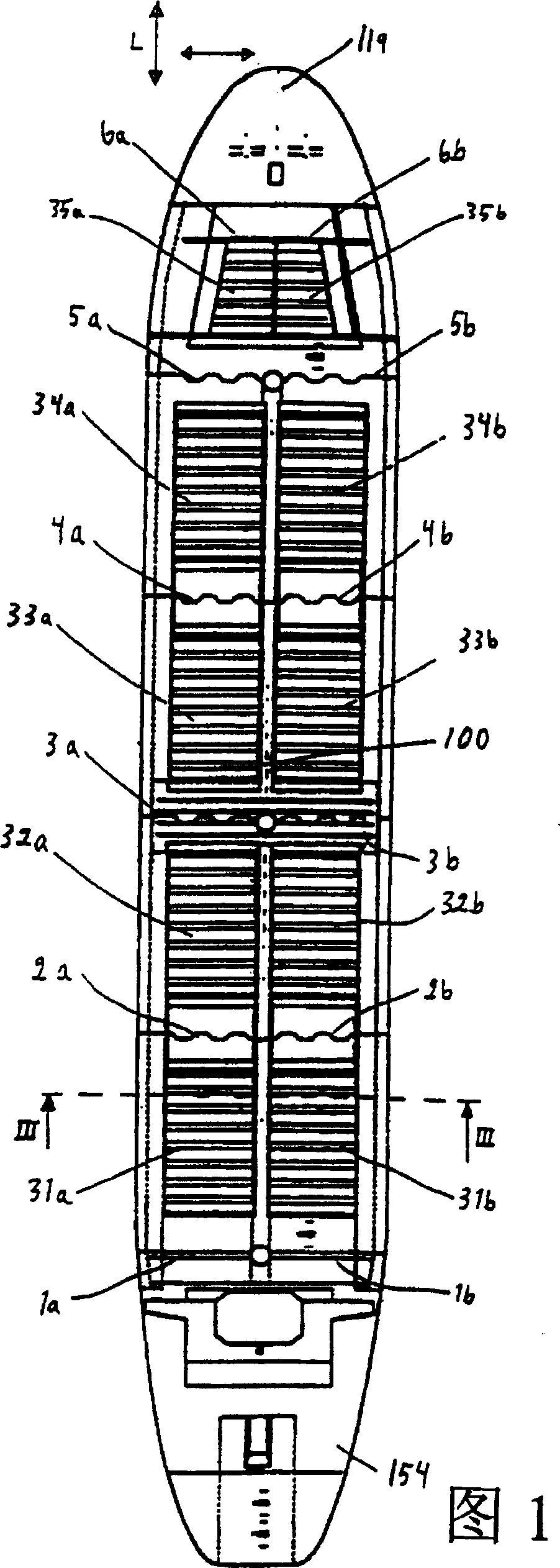

[0028] Figure 1 is a plan view, ie a view from above, of an OBO type or bulk carrier type vessel according to the invention. The vessel has a bow 119, a stern 154, transverse bulkheads 1-5 and a longitudinal axis bulkhead 100 intersecting the transverse bulkheads. The transverse bulkheads and the axial bulkheads form cargo holds 11-15 for the transport of bulk cargo. And the hatches 21-25 which can be opened and closed by the hatch covers 31-35 lead to the cargo compartment.

[0029] The present invention relates to cargo tanks 11-14 covered by single-piece hatch covers 31-34. The cargo hold 15 (see Fig. 2) is a smaller forward cargo hold without a longitudinal axis bulkhead and is covered by split hatch covers 35a, b of known construction.

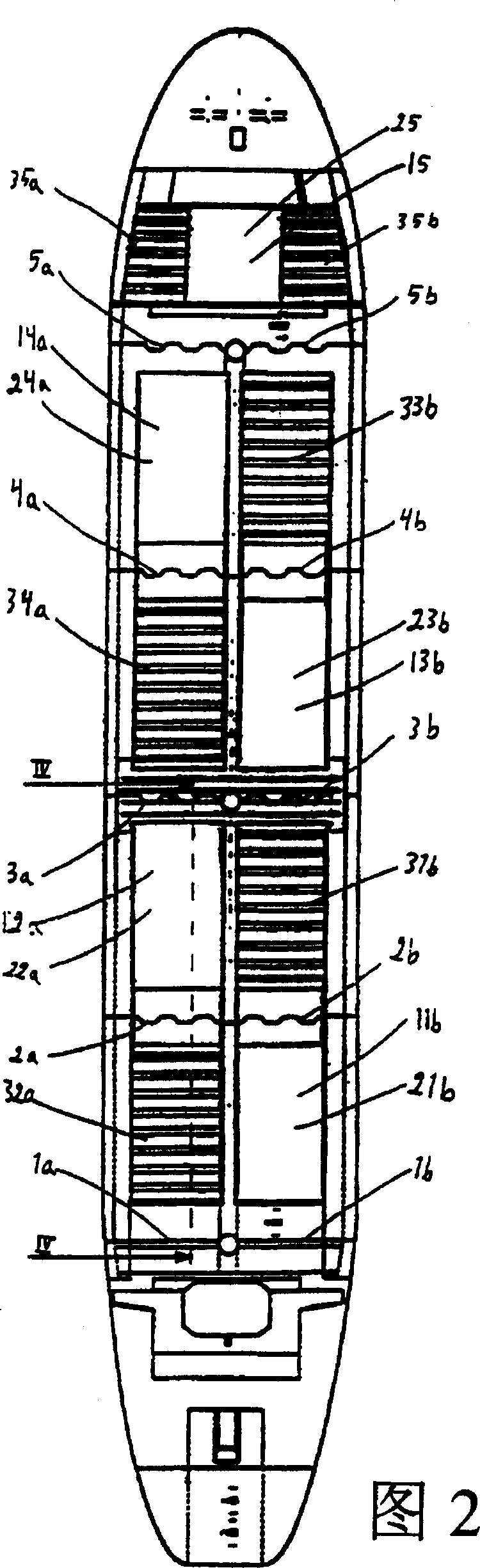

[0030] Figure 2 shows the same vessel, except that the hatches in Figure 1 are closed, whereas half of the hatches 31-34 in Figure 2 are open, which can be achieved by lifting and moving the hatch covers 31-34 to the position where the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com