Hold-down conveying roller and groove roller matched with hold-down conveying roller

A technology of conveying rollers and cooperating rollers, which is applied in the direction of winding strips, thin material handling, transportation and packaging, etc., can solve the problems of inconvenient collection of materials, sagging materials, insufficient tension, etc., and achieves long duration and improved clamping. force, the effect of improving rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

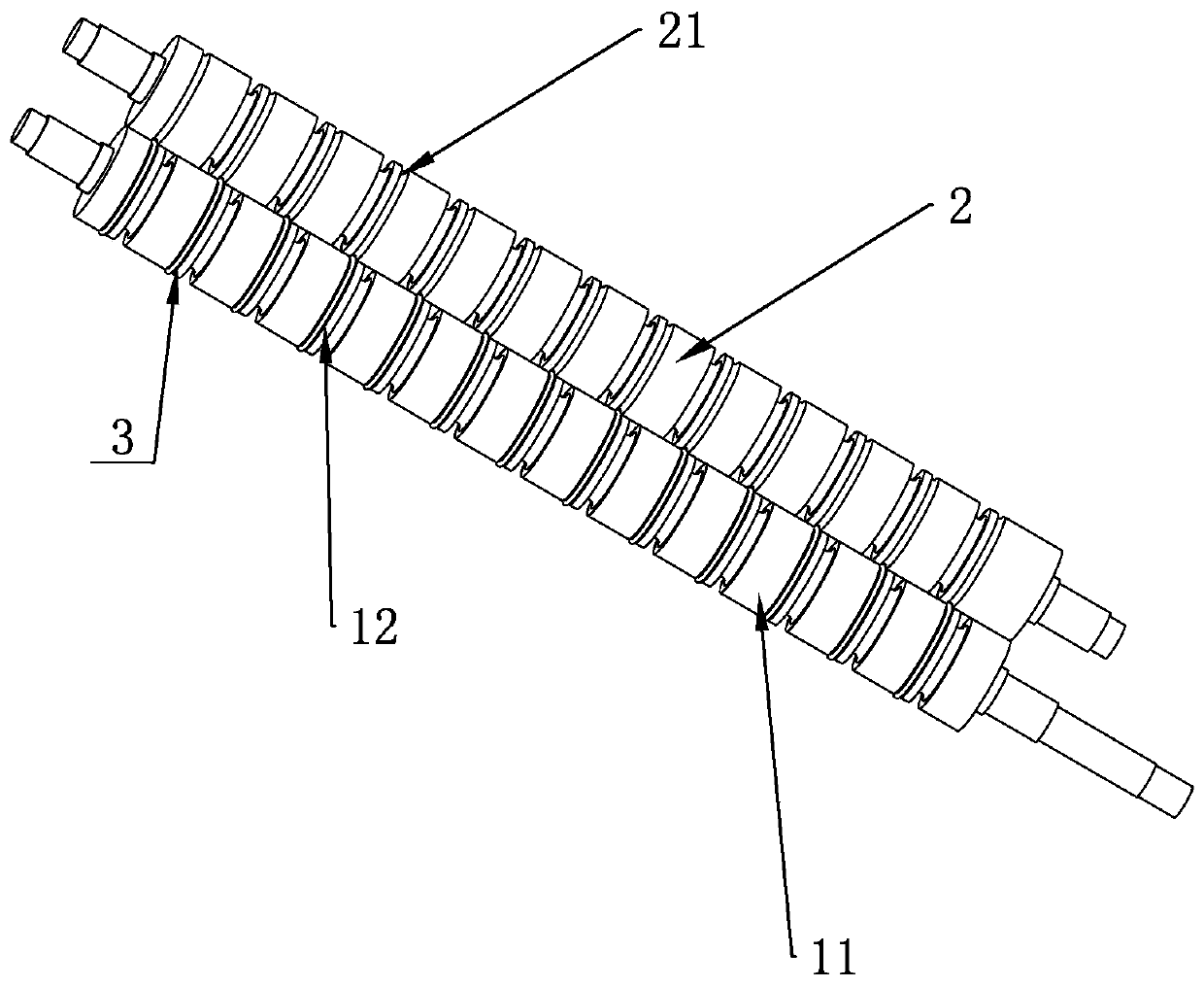

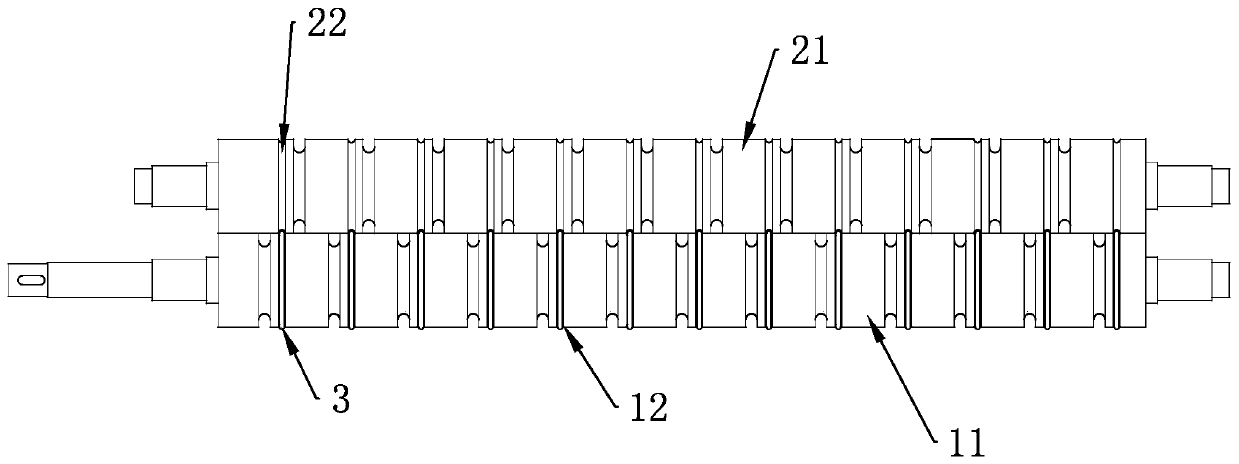

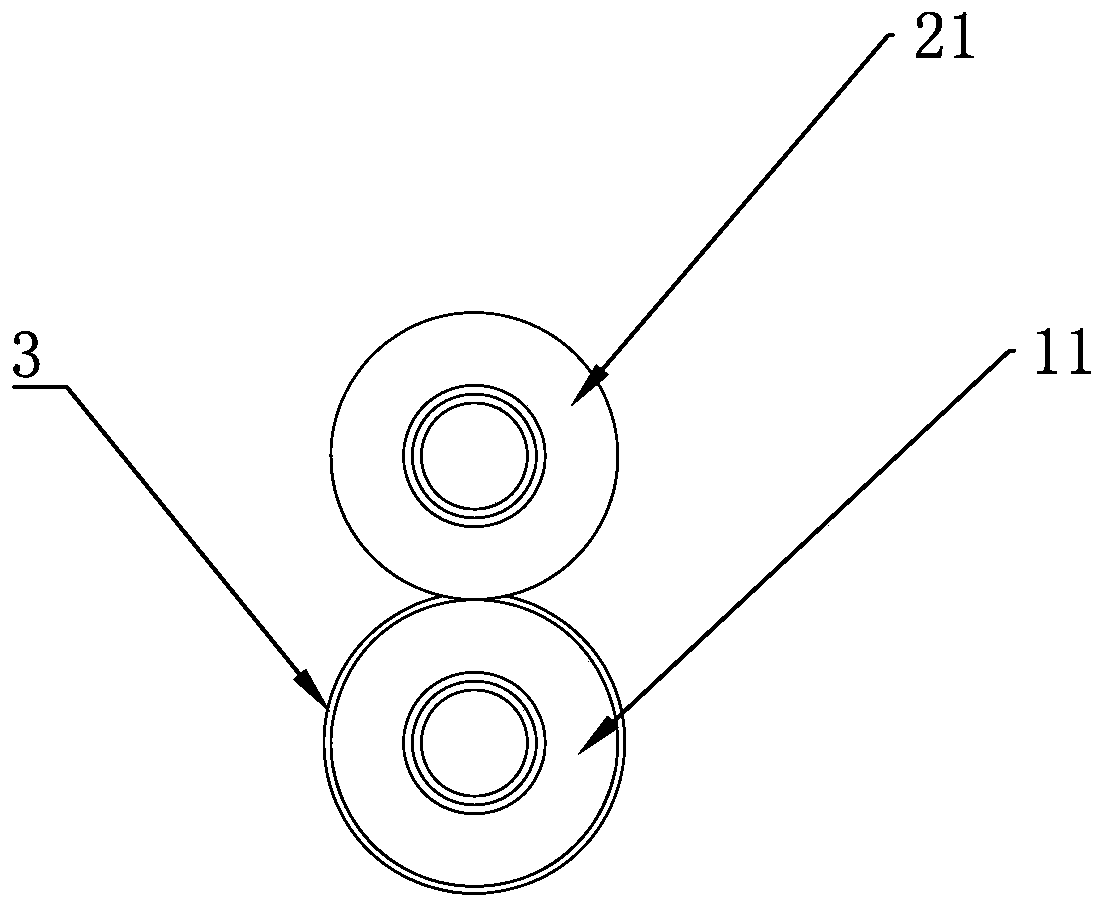

[0057] Embodiment 1 refers to the structure of a pressing conveying roller shown in the accompanying drawings, comprising a columnar roller body 11 and transmission shafts arranged on both end faces of the roller body 11, and the outer surface of the roller body 11 is provided with a plurality of concaves. Groove 12, the groove 12 is an annular groove, which is arranged around the roller body 11 parallel to the radial plane of the roller body 11, and the groove 12 is provided with a spring bar 3 that coincides with the path of the groove 12.

[0058] The spring bars 3 are fixed end to end by welding to prevent the spring bars 3 from coming off during use. It can be seen intuitively from the drawings that the surface of the spring bar 3 protrudes from the surface of the roller body 11. In this embodiment, in order to make the whole stable and balanced, the spring bar 3 preferably adopts equidistant springs with constant diameters. The spring bar 3 can be made of steel alloy or ...

Embodiment 2

[0062] Embodiment 2 The difference between this embodiment and Embodiment 1 is that the ring groove is or is inclined to the radial plane of the roller body 11, that is, in this embodiment, the groove 12 is an inclined groove. Correspondingly, the embodiment The groove 12 in 1 is a straight groove.

Embodiment 3

[0063] Embodiment 3 The difference between this embodiment and the above embodiment is that the groove 12 is a spiral groove, which is the effect of protruding the spring bar 3. The number of spiral grooves is preferably more than two, and the parallel distribution is the first. A staggered distribution can also be used. However, under the staggered distribution, in order to make the roller body 11 rotate and convey the material, it is best to maintain the same force on the material every time it passes. It is necessary to control the number and appropriate spacing of the spiral grooves used in the staggered distribution according to the actual situation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com