Constant-current source intelligent control cabinet for crude oil electric dehydration

An intelligent control cabinet and electric dehydration technology, applied in the field of control cabinets, can solve the problems of difficulty in adapting to the complex on-site environment of crude oil dehydration production, no intelligent control mode, low device integration, etc., achieving flexible and convenient control modes and improving explosion-proof grades. and safety, and the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

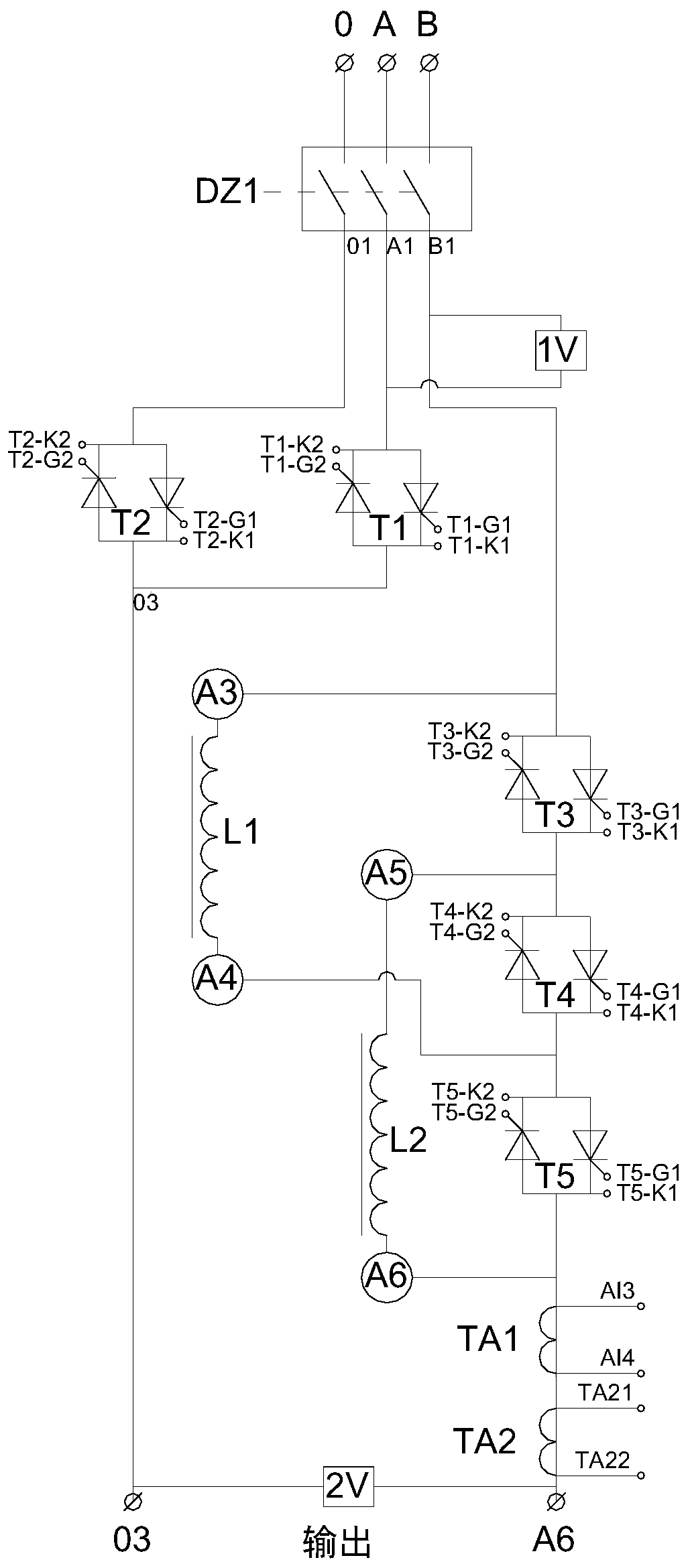

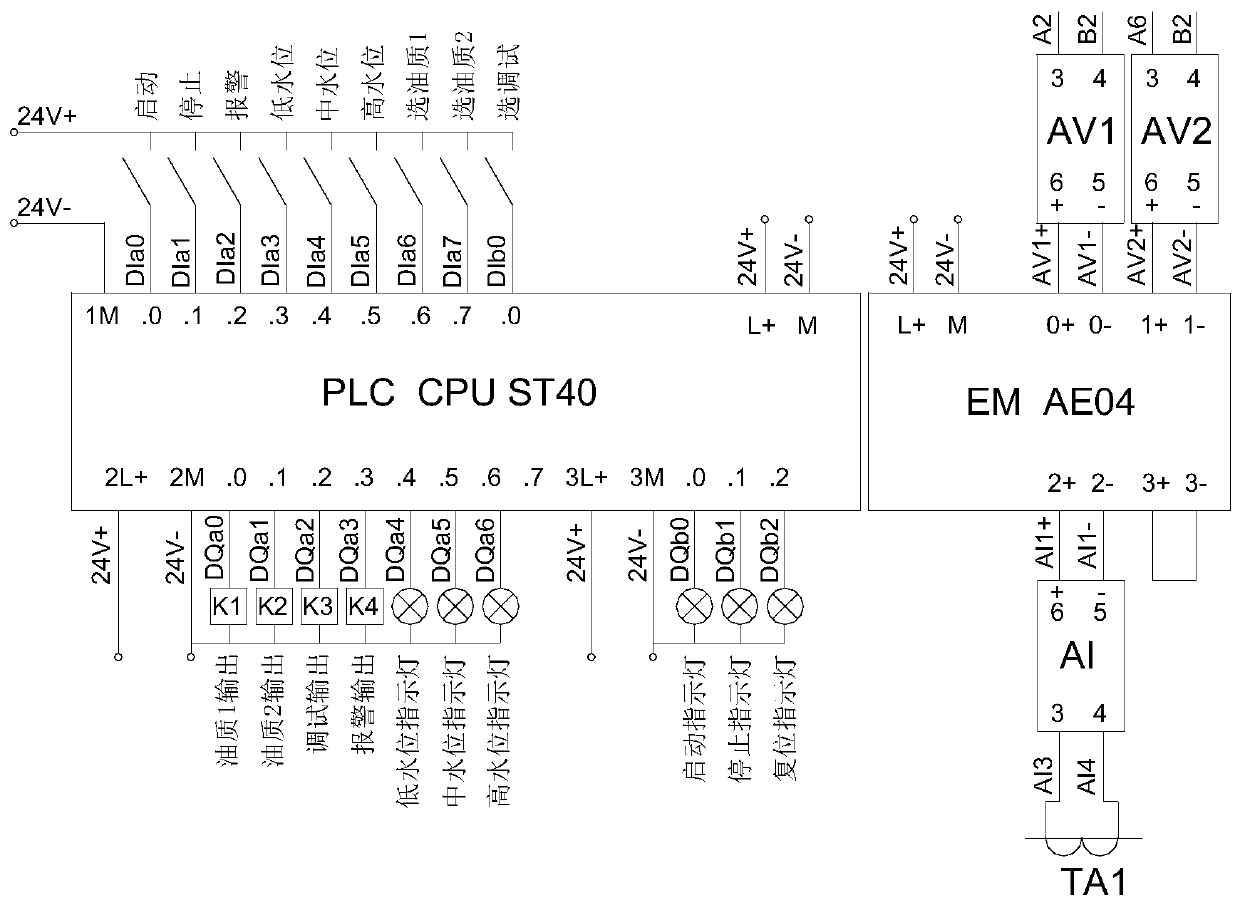

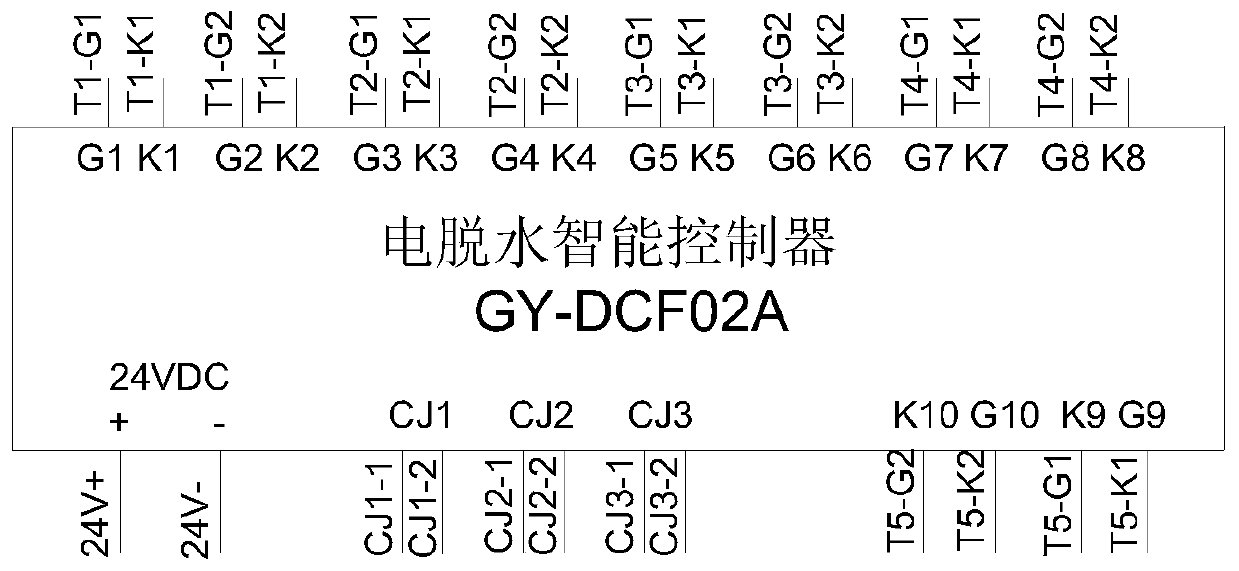

[0017] The specific structure of the intelligent control cabinet of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0018] Such as figure 1 with figure 2 shown. The constant current source intelligent control cabinet for electric dehydration of crude oil of the present invention is composed of a cabinet body, a power supply main circuit and a control circuit installed in the cabinet body. The main circuit of the power supply is connected with a thyristor device as a switch to control the on-off of the main circuit. The selection control of the inductor in the main circuit is also controlled by the thyristor device as a switch. The opening and closing of each thyristor device is controlled by an intelligent dedicated controller. Control, and the detection, display and control devices used for working status are all connected to a PLC controller for control.

[0019] The thyristors are controlled by a dedicated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com