Processing technology for austenitic stainless steel medical instrument part

A technology for austenitic stainless steel and medical equipment, applied in electrolytic components, electrolytic process, metal rolling, etc., can solve the problems of long processing time, low production efficiency, material waste, etc., and achieve production cost reduction, production efficiency improvement, Position-accurate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

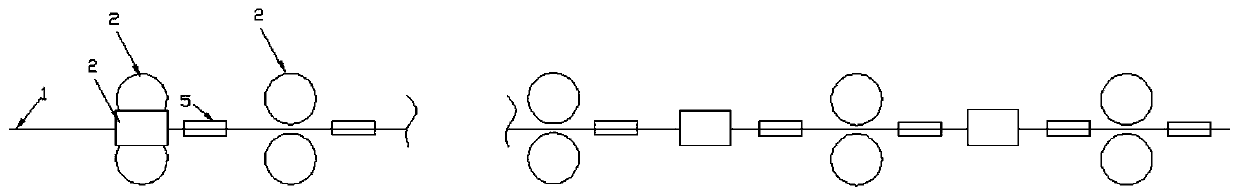

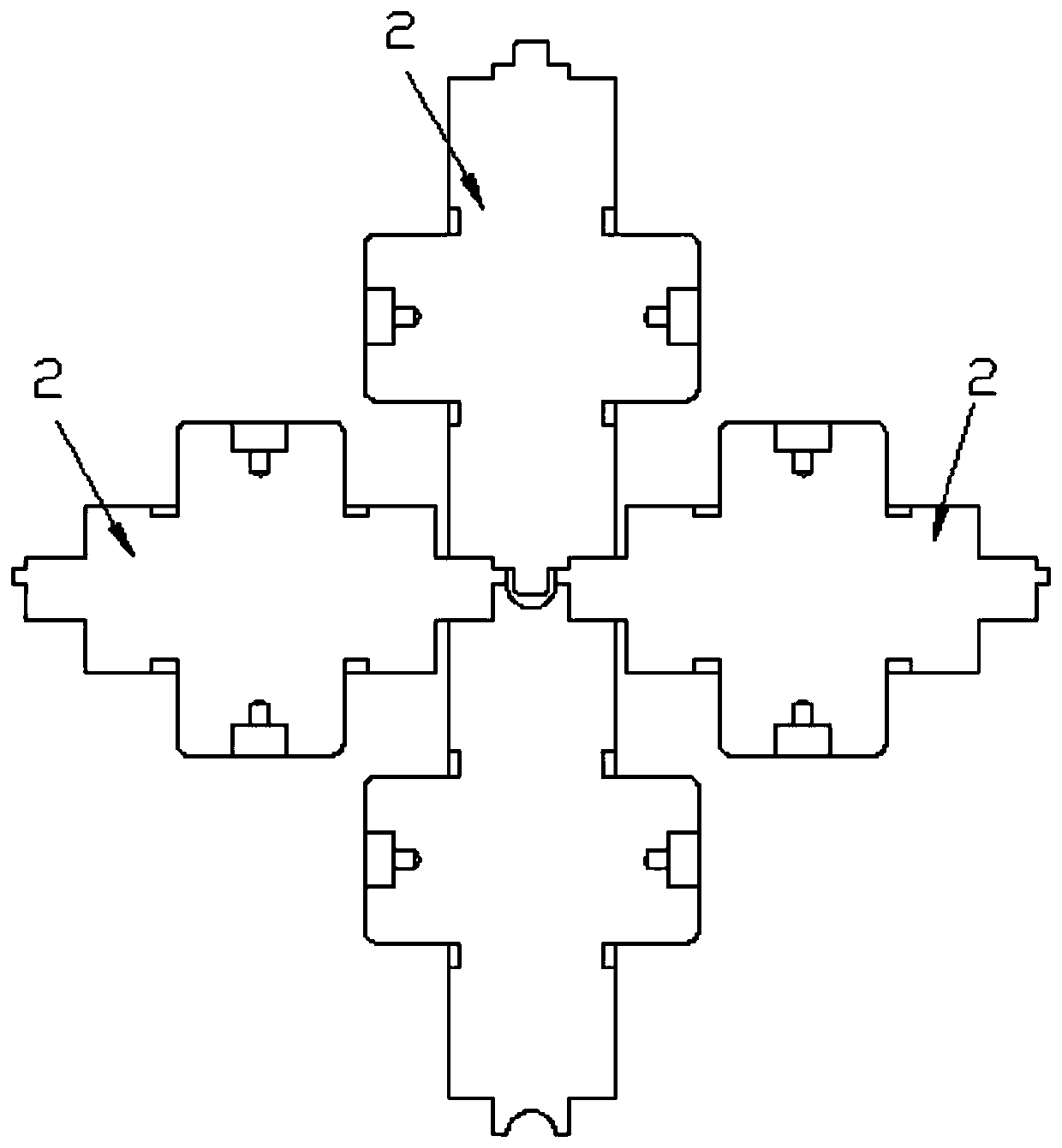

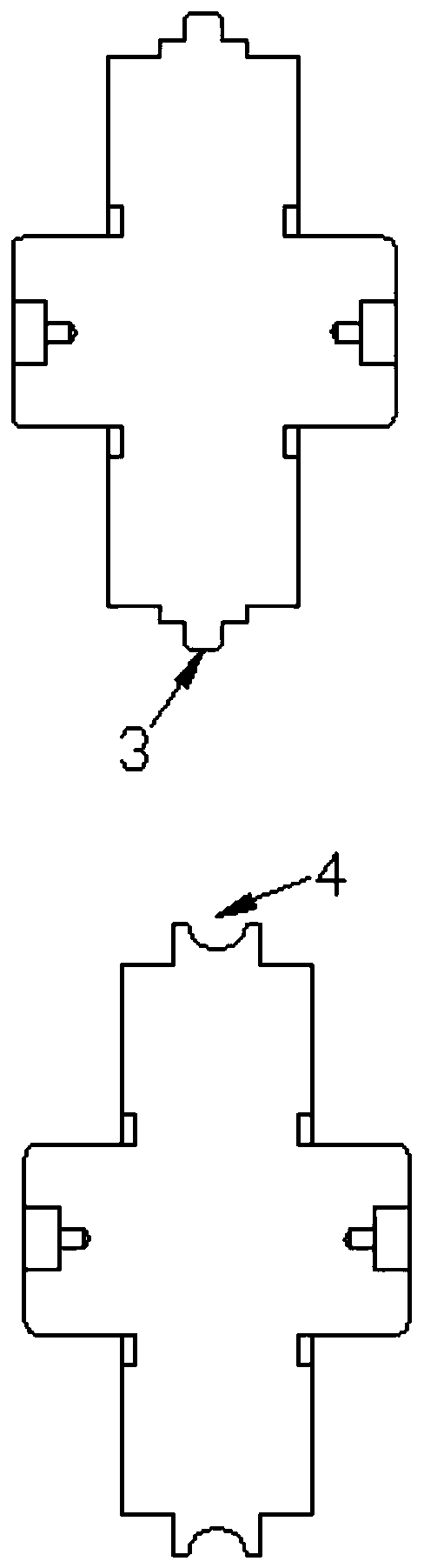

[0022] Such as Figure 1 to Figure 4 As shown, the present invention is a processing technology for austenitic stainless steel medical device parts, including making medical device parts 6 after austenitic stainless steel disc 1 (i.e. wire rod) is cold-rolled for 10-13 passes. The 10-13 cold-rolling process also includes annealing the austenitic stainless steel disc 1 for 9-11 times, and the rolling deformation rate of each cold-rolling process compared with the previous cold-rolling process Less than 75%; the annealing temperature is 1000°C to 1200°C. The speed of the stainless steel disc 1 passing through the rolling zone is V1, and the speed through the heat treatment zone is V2. In the heat treatment process, a tube furnace 5 is used, and the furnace length of the tube furnace 5 is 8-10m; 0m / min<V1<20m / min, 1m / min<V2<8m / min. The diameter of the disc 1 is 17±0.3 mm; the material of the disc 1 is 301 stainless steel. The annealing temperature is 1050°C to 1080°C. The ro...

Embodiment 2

[0024] The difference from Example 1 is that after the last cold rolling process, the surface electrolytic treatment is carried out on the finished medical device parts, after electrolysis, it is cleaned, and after cleaning, it is air-dried. After electrolytic cleaning and air-drying, the medical device parts are soaked in After 10 hours in the liquid medicine, air-dry, and apply a layer of water-proof protective film on the surface of medical device parts after air-drying. Nano-robots for entering the human body to reach the lesion to destroy tumors are set in the corroded micropores on the surface of medical device parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com