Multifunctional automatic cable winding type excavator for mining

An excavator and multi-functional technology, which is applied in the field of mining multi-functional automatic cable-reeling excavators, can solve the problem of easily touching the roadway roof or anchor rods, anchor cables, reducing the safety factor of mine construction, and being afraid to move or rotate easily. and other problems, to avoid rolling back cables, facilitate continuous construction, and strengthen the stability of the excavator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

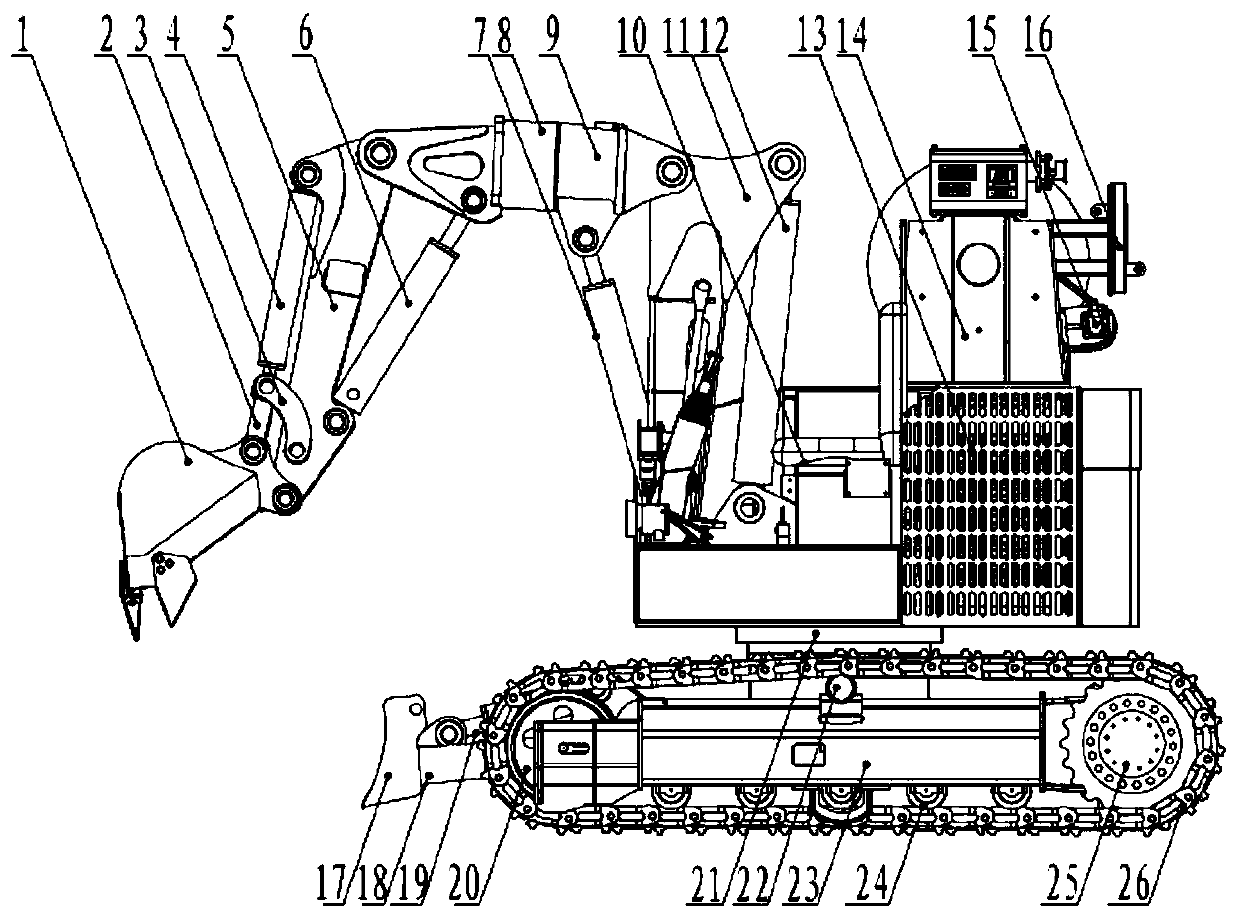

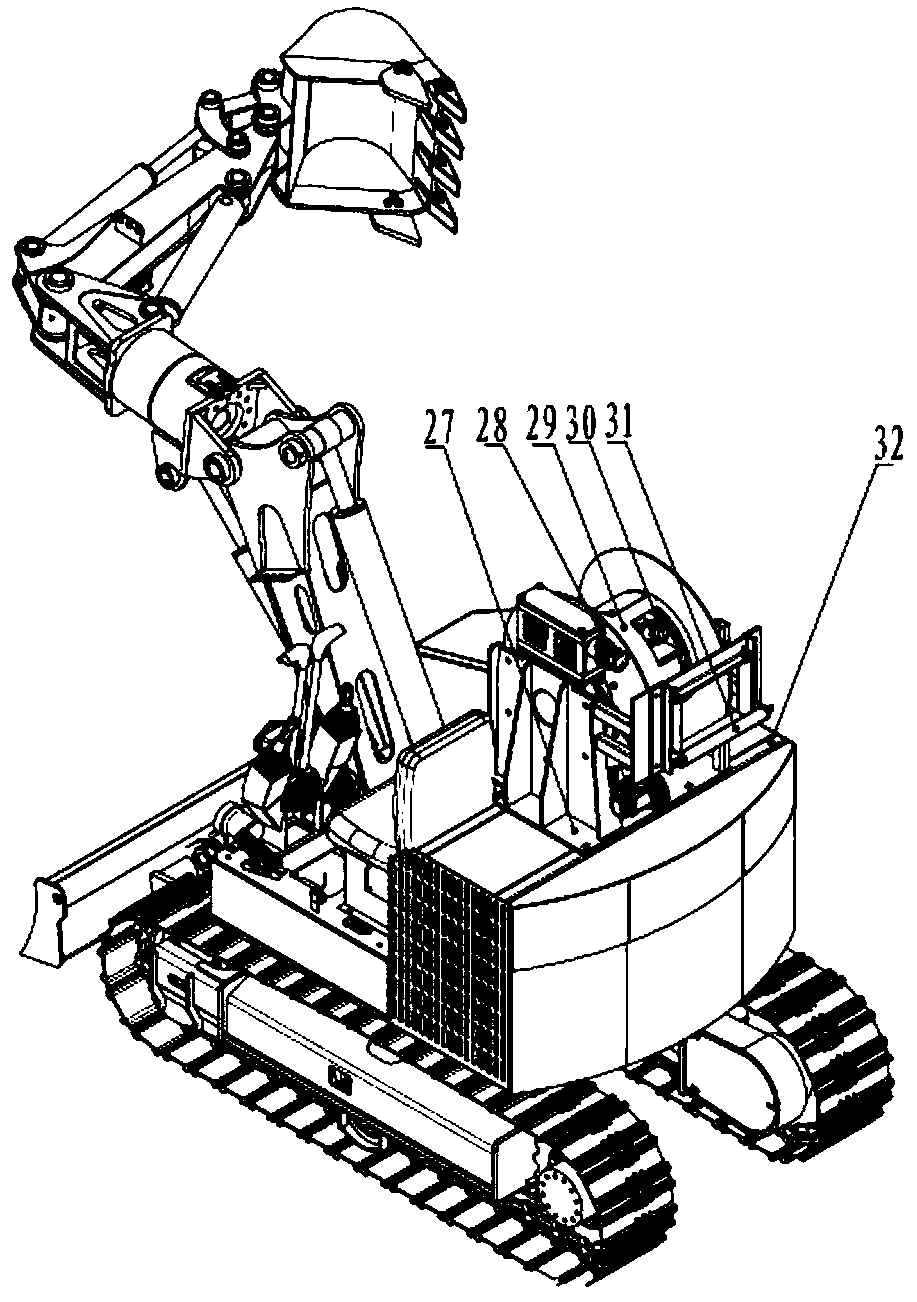

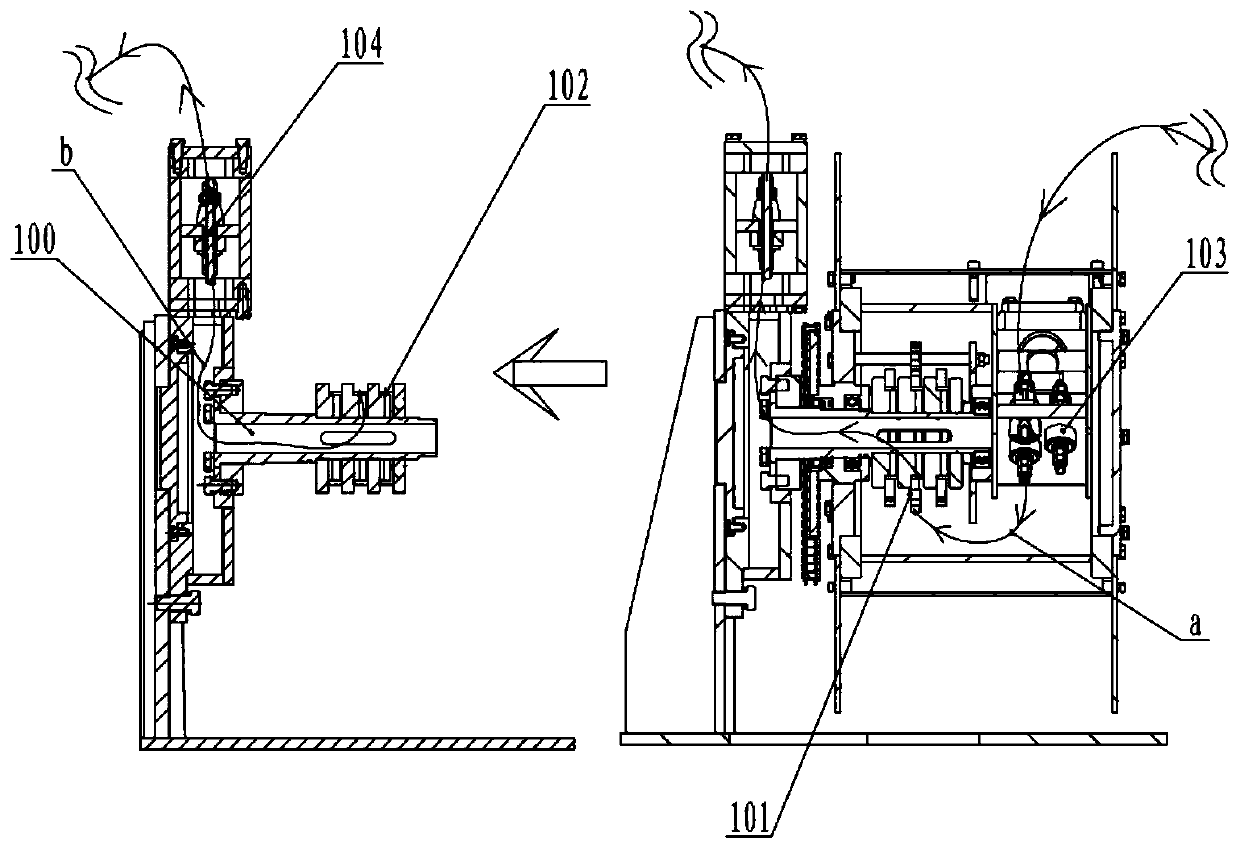

[0032] Such as Figure 1 to Figure 6 Shown, a kind of multi-functional automatic cable-coiling excavator for mining includes a walking drive device, an excavating device, a bulldozing device and a cable-coiling device.

[0033] The walking drive device includes a chassis frame 23, which is symmetrically arranged on both sides of the chassis frame 23. Chassis frame 23 front and rear ends are equipped with guide wheel 20, driving speed reducer 25 respectively, and chassis frame 23 undersides are equipped with support roller 24, and chassis frame 23 upper sides are equipped with carrier sprocket wheel 22; Track rollers 24, supporting sprockets 22 are provided with crawler belts 26 outside. The supporting roller 24 adopts a floating seal, and the operation is stable and reliable; the guide wheel 20 plays the three major roles of guiding, supporting, and track tensioning;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com