Sound insulation device

A technology of sound insulation device and sound insulation felt, which is applied in the directions of sound insulation, insulation layer, building components, etc., can solve the problems of inability to limit sound transmission in all directions, poor sound insulation effect, etc., and achieve the effect of reducing vibration and weakening strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

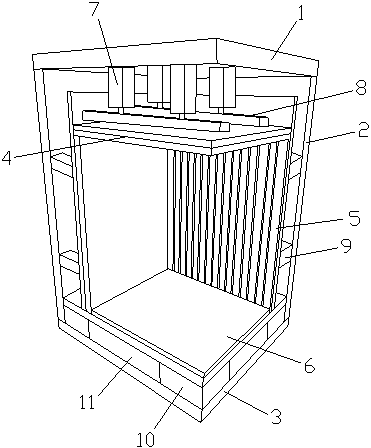

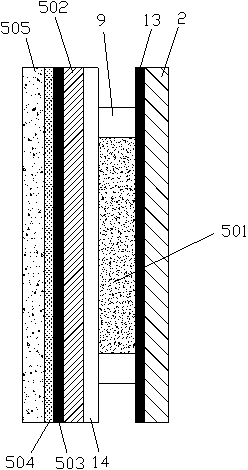

[0037] Such as figure 1 As shown, the present invention provides a sound insulation device, comprising an upper base plate 1, a side base plate 2 and a lower base plate 3, a first upper sound insulation felt 12 is installed on the inner side of the upper base plate 1, and a sound insulation top plate 4 is provided on the inner side of the upper base plate 1, The inner surface of the side base plate 2 is provided with a first side sound-insulating felt 13, the inner side of the side base plate 2 is provided with a sound-insulating side plate 5, the inner side of the lower base plate 3 is provided with a sound-insulating bottom plate 6, a sound-insulating top plate 4, a sound-insulating side plate 5 and a sound-insulating bottom plate 6 A sealed space is formed, a first keel 8 is installed on the outer surface of the sound-insulating top plate 4, a first damping device 7 is installed between the first keel 8 and the upper base plate 1, and a second keel 14 is installed on the out...

Embodiment 2

[0039] Present embodiment 2 adopts following preferred scheme on the basis of embodiment 1:

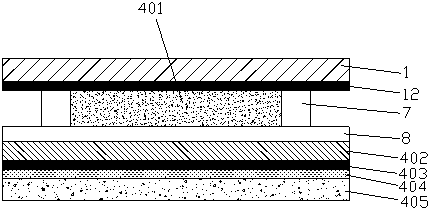

[0040] Such as figure 2As shown, specifically, the sound insulation roof 4 includes a first sound insulation board 402 and a first sound absorption board 405, the first sound insulation board 402 is connected to the first keel 8, and the lower end of the first sound insulation board 402 is provided with a second upper sound insulation felt 403, The second upper sound insulation felt 403 is installed and connected with the bottom surface of the first sound insulation material 401, and the first woodworking board 404 is arranged between the second upper sound insulation felt 403 and the first sound absorbing board 405, and the first wood working board 404 and the first sound absorbing board 405 Adhesive connection, the first sound insulation material 401 is filled between the first keel 8 and the first upper sound insulation felt 12, the first sound insulation material 401 is sound ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com