Cooling water pump for automobile engine

A technology of automobile engine and cooling water pump, which is applied in the direction of engine cooling, engine components, machines/engines, etc. It can solve the problems affecting the normal circulation of coolant and the normal operation of the pump body, so as to improve the heat dissipation and cooling effect and the service life Long, smooth circulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

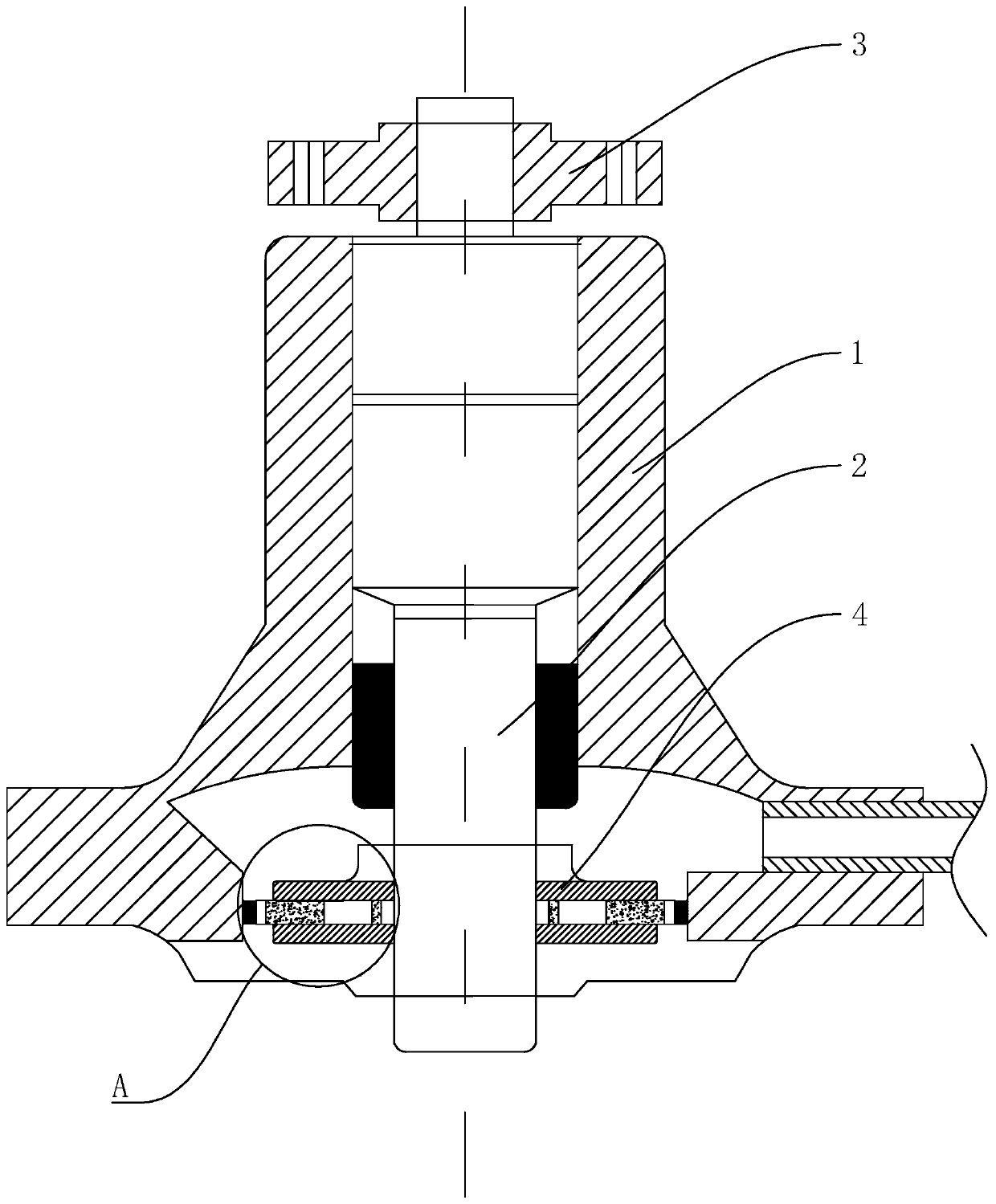

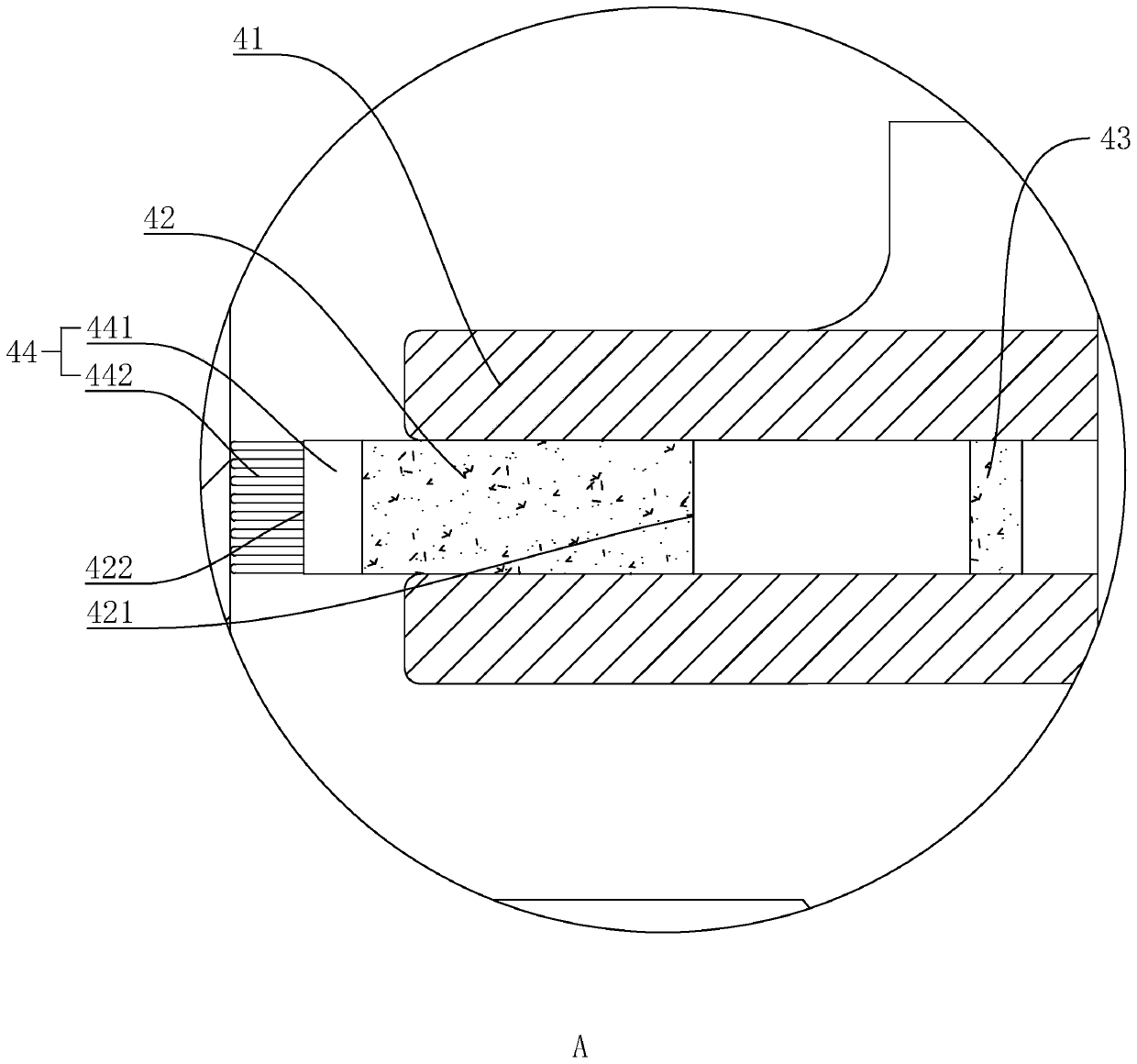

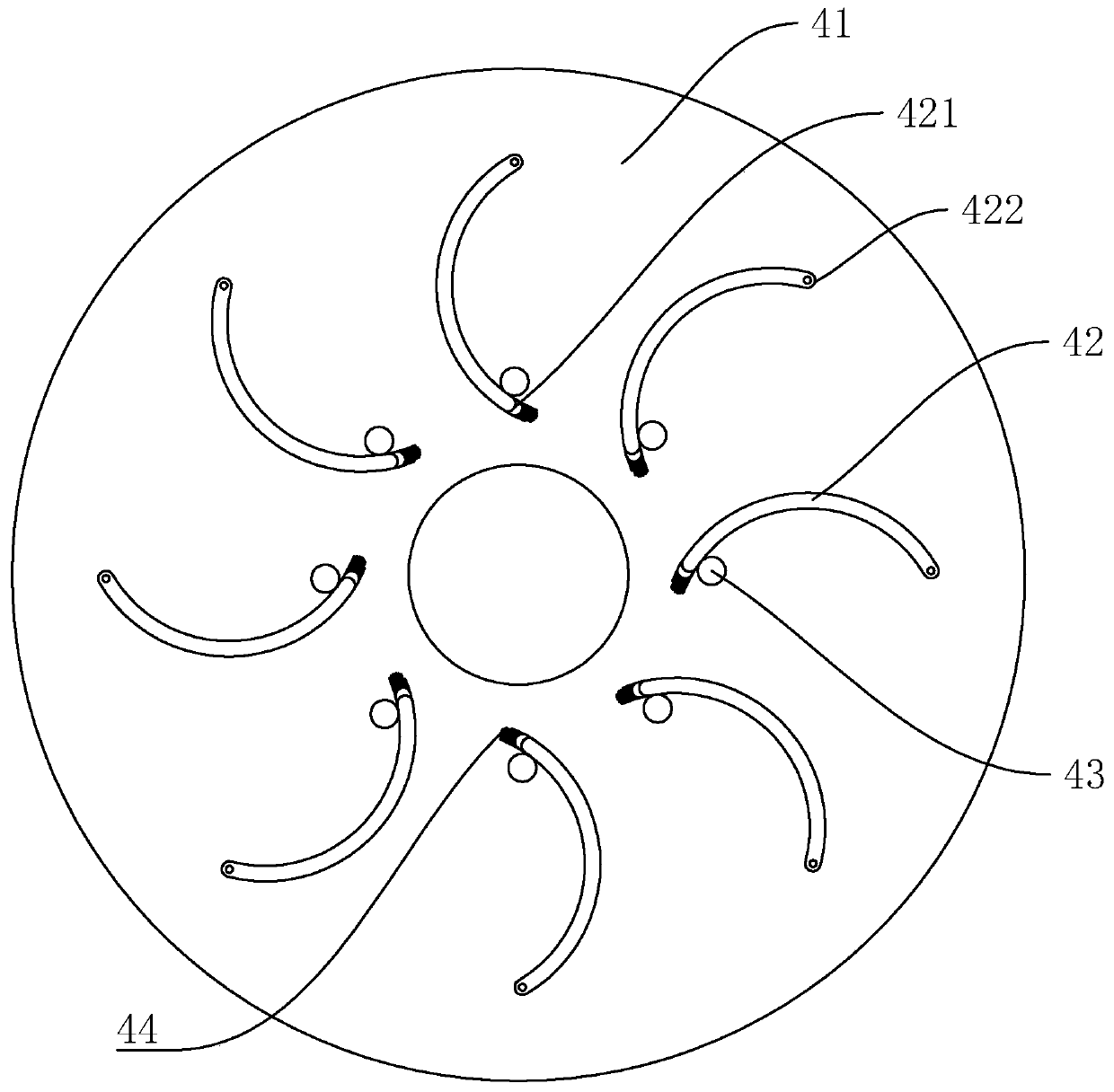

[0023] The cooling water pump for an automobile engine provided in this embodiment has a structure such as Figure 1 to Figure 4 As shown, the pump body 1 is included. The inner interference fit of the pump body 1 is provided with a shaft-connected bearing 2 and the upper and lower ends of the shaft-connected bearing 2 are respectively connected with a flange 3 and an impeller device 4. The impeller device 4 includes two circular clamping plates 41 parallel to each other. The two circular clamping plates 41 are arranged at intervals in the vertical direction. A number of blades 42 are rotatably connected between the two circular clamping plates 41. The rotation of the blades 42 The shaft is arranged in the vertical direction and is arranged at the end of the blade 42 itself close to the outer side of the impeller. A number of limit posts 43 are connected between the two circular clamping plates 41. The limit posts 43 are used to conflict with the corresponding blade 42. A clean...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com