A release gas temperature detection platform for vacuum cleaner processing

A gas temperature and vacuum cleaner technology, which is applied in the field of released gas temperature detection table for vacuum cleaner processing, can solve the problems of inaccurate measurement, poor sealing performance, lack of thermal insulation structure, etc., to optimize thermal insulation effect, improve accuracy, increase sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

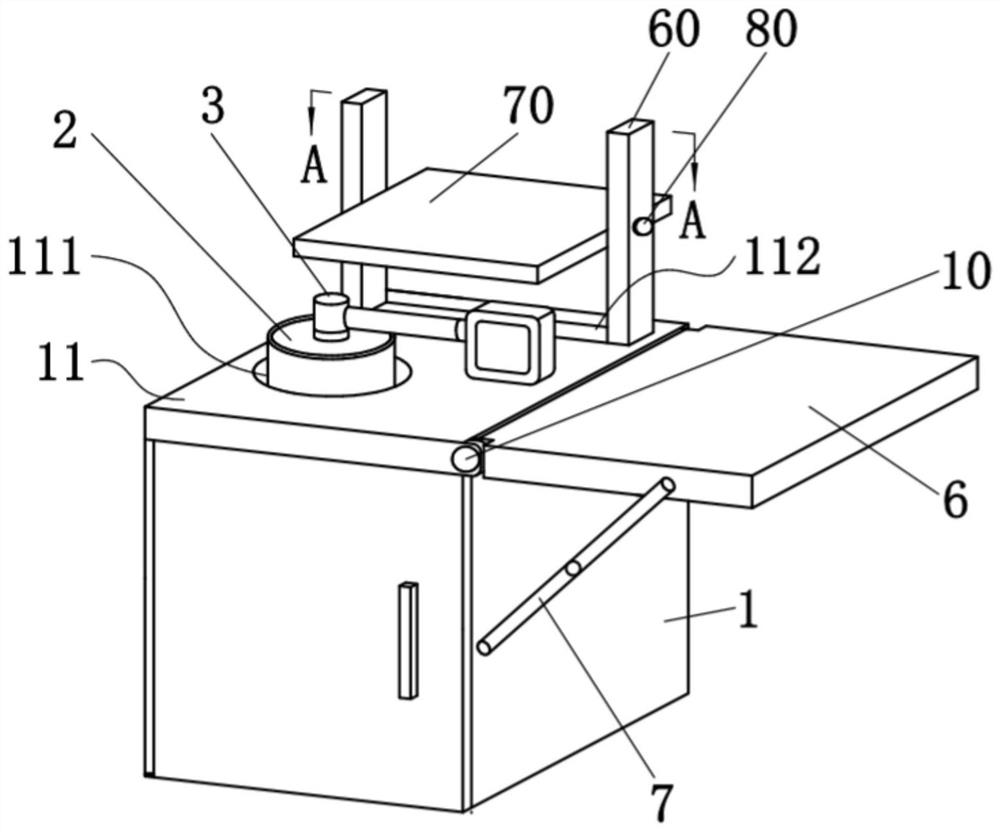

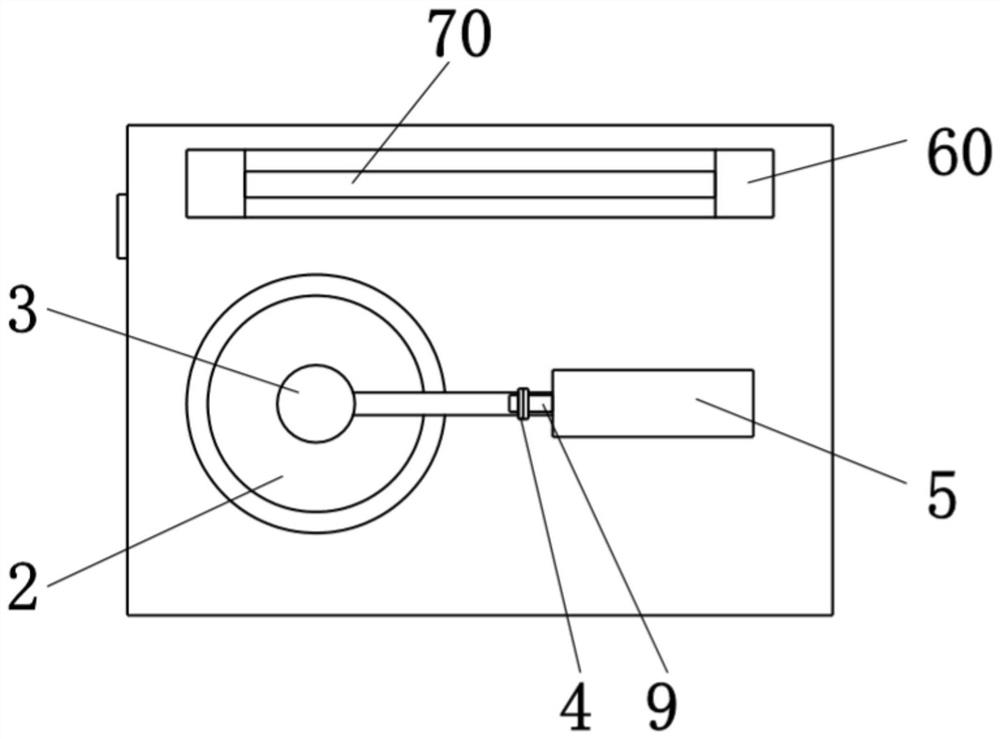

[0025] Such as figure 1 with figure 2 As shown, a release gas temperature detection platform for vacuum cleaner processing includes a cabinet body 1, wherein the top of the cabinet body 1 has a first platen 11, and the top end of the first platen 11 is provided with a groove 111, The groove 111 is inserted with a gas storage tank 2, the top of the gas storage tank 2 is plugged with a conduit 3, and the outside of the conduit 3 is threaded with a gas thermometer 5 through a threaded seat 4, through which the gas storage tank 2 And conduit 3 can guarantee the constant volume of gas.

[0026] Such as image 3 As shown, the connection end of the gas thermometer 5 is fixed with a detection head 9 , and the detection head 9 is located inside the conduit 3 .

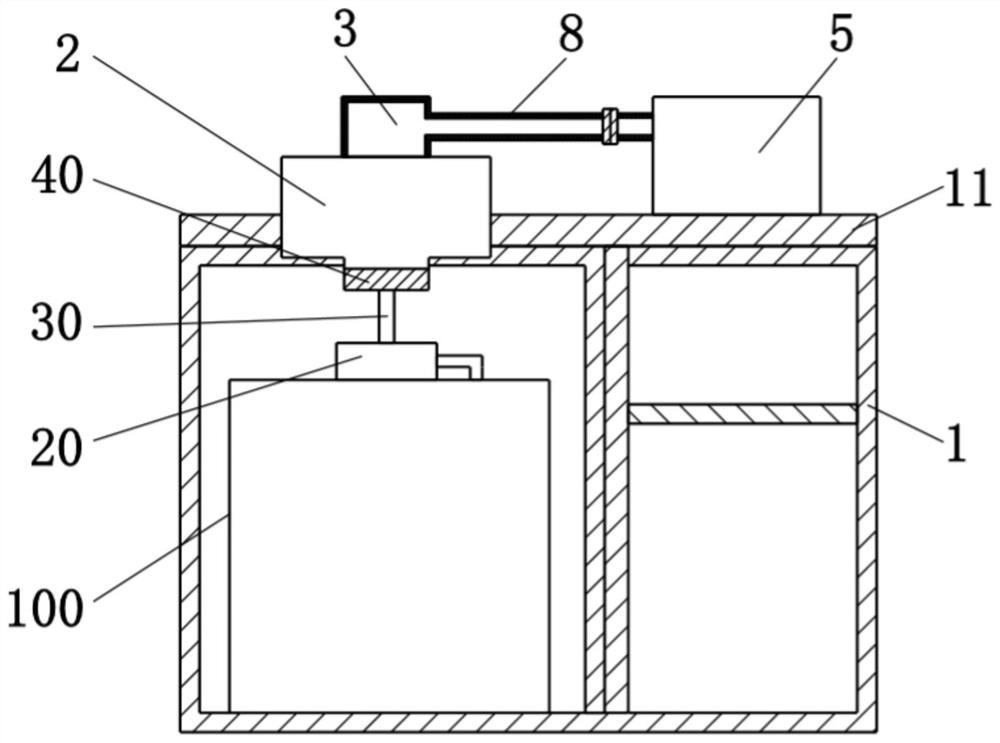

[0027] Such as figure 2 As shown, the interior of the cabinet 1 is provided with a vacuum cleaner body 100, the top of the vacuum cleaner body 100 is fixedly provided with an air pump 20, and the top of the air pump 20 is...

Embodiment 2

[0031] Such as figure 2 As shown, on the basis of Embodiment 1, the inner wall of the conduit 3 is fixedly provided with an insulation layer 8, and the insulation layer 8 is made of foam cotton material, thereby optimizing the insulation effect of the conduit 3 and avoiding the need for vacuum cleaner processing. The temperature of the released gas changes after passing through the conduit 3, which improves the accuracy of measurement.

Embodiment 3

[0033] Such as figure 1 As shown, on the basis of the second embodiment, the vacuum cleaner processing release gas temperature detection platform also includes a second platform 6, and the second platform 6 is rotatably connected to one of the first platform 11 through a rotating shaft 10. side, and the second platform 6 is fixedly connected to one side of the cabinet body 1 through a pair of folding structural members 7, and the pair of folding structural members 7 are respectively located on the inner and outer sides of the second platform 6 , thereby increasing the area of the workbench, and it can be folded and contracted. When the area of the workbench needs to be enlarged, the second platen 6 is rotated to be parallel to the first platen 11 .

[0034] During specific use, first open the cabinet door on the front of the cabinet body 1 by the handle, place the vacuum cleaner body 100 to be tested inside the cabinet body 1, connect the tube body 30 and one end of the co...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap