Preparation method of mixed PVA film and polarizer

一种混合型、混合染料的技术,应用在光学、偏振元件、光学元件等方向,能够解决碘系偏光片耐久性差、不适应高温高湿环境等问题,达到优偏光性、好偏光性和耐 High temperature and high humidity characteristics, the effect of improving the characteristics of high temperature and high humidity resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

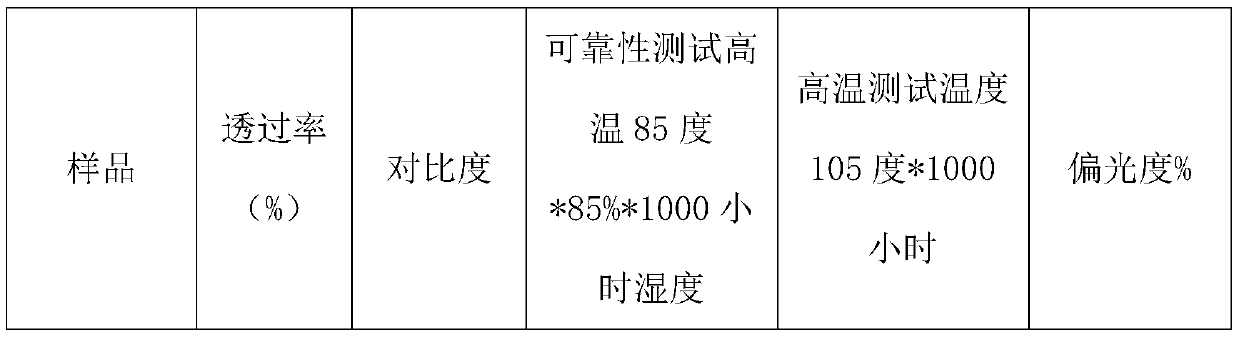

Examples

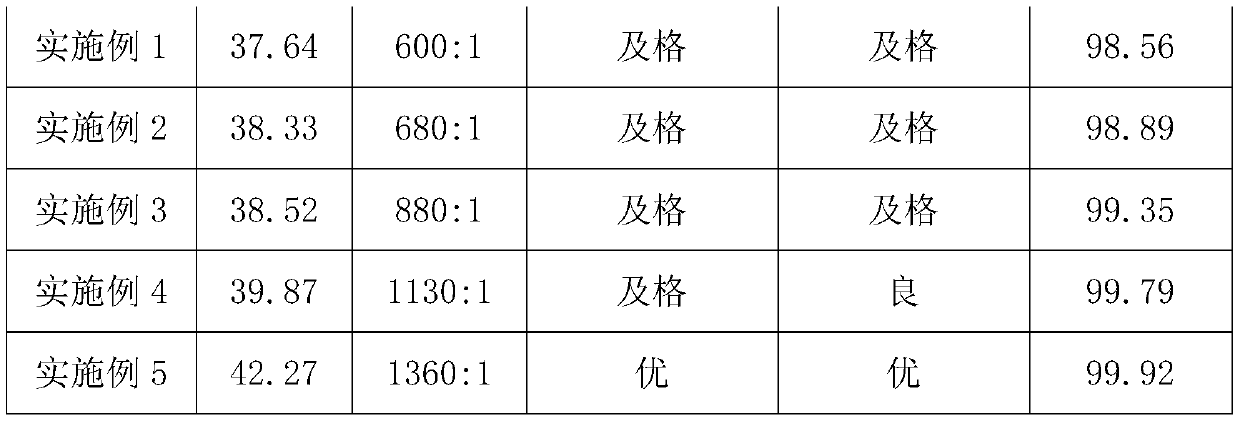

Embodiment 1

[0033] A kind of preparation method of mixed type PVA film, described method comprises steps:

[0034] Step S1. Washing: placing the PVA base film in a washing tank;

[0035] Step S2. swelling: place the cleaned PVA base film in a swelling tank containing 0.3% boric acid solution for swelling treatment;

[0036] Step S3. Dyeing: immerse the swollen PVA basement membrane in a dyeing tank containing a dyeing liquid for dyeing treatment, the dyeing liquid includes by mass percentage: 1.92% dichroic mixed dye, 0.7% iodine, and 1.8% potassium iodide %, boric acid 0.1%;

[0037] Step S4. Stretching: After the dyeing is finished, the PVA film is first cleaned in the cleaning tank, and then enters the stretching tank for stretching. The stretching ratio is 4.6 times that of the PVA base film, and the stretching tank solution is 3% boric acid solution. The temperature of the stretching bath is 52°C;

[0038] Step S5. Complementary color: the stretched PVA film is dipped in a color-r...

Embodiment 2

[0042] A kind of preparation method of mixed type PVA film, described method comprises steps:

[0043] Step S1. Washing: placing the PVA base film in a washing tank;

[0044] Step S2. swelling: place the cleaned PVA base film in a swelling tank containing 0.5% boric acid solution for swelling treatment;

[0045] Step S3. Dyeing: immerse the swelled PVA basement membrane in a dyeing tank containing a dyeing solution for dyeing treatment, the dyeing solution includes by mass percentage: 1.7% dichroic mixed dye, 0.85% iodine, 1.65% potassium iodide %, boric acid 0.3%;

[0046] Step S4. Stretching: After the dyeing is finished, the PVA film is first cleaned in the cleaning tank, and then enters the stretching tank for stretching. The stretching ratio is 4.93 times that of the PVA base film, and the stretching tank solution is 2.8% boric acid solution. The temperature of the stretching bath is 52°C;

[0047] Step S5. Complementary color: the stretched PVA film is dipped in a col...

Embodiment 3

[0051] A kind of preparation method of mixed type PVA film, described method comprises steps:

[0052] Step S1. Washing: placing the PVA base film in a washing tank;

[0053] Step S2. swelling: place the cleaned PVA base film in a swelling tank containing 0.5% boric acid solution for swelling treatment;

[0054] Step S3. Dyeing: immerse the swollen PVA basement membrane in a dyeing tank containing a dyeing liquid for dyeing treatment, the dyeing liquid includes: 1.6% dichroic mixed dye, 0.9% iodine, 1.75 potassium iodide by mass percentage %, boric acid 0.5%;

[0055] Step S4. Stretching: After the dyeing is finished, the PVA film is first cleaned in the cleaning tank, and then enters the stretching tank for stretching. The stretching ratio is 5.12 times that of the PVA base film, and the stretching tank solution is 3.1% boric acid solution. The temperature of the stretching bath is 52°C;

[0056] Step S5. Complementary color: the stretched PVA film is dipped in a color-rep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com