Remote cooperative control technology and method for fully-mechanized excavating complete equipment

A collaborative control and complete set of technology, applied in the direction of program control, electrical program control, general control system, etc., can solve problems such as inaccurate relative positions of three machines, cumbersome operator confirmation, safety accidents, etc., and achieve scientific linkage and low delay , improve the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing.

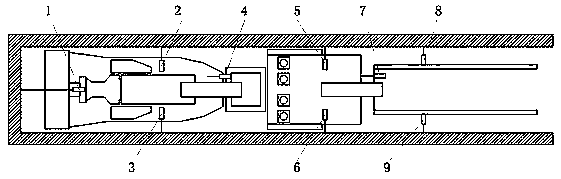

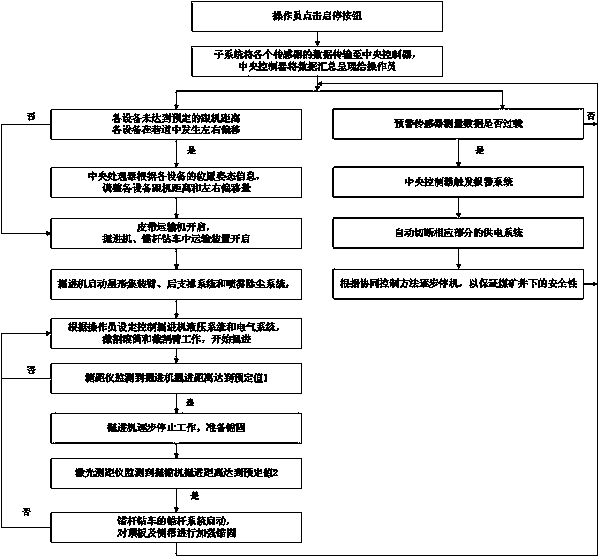

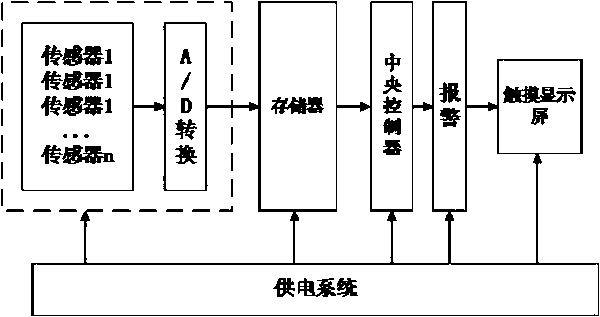

[0032] The remote cooperative control technology and method for the complete set of fully mechanized excavation equipment provided by the present invention includes a touch screen display, a wireless communication module, a central controller, and a roadheader control subsystem connected and controlled by it, a bolter control subsystem, and a belt conveyor control subsystem. subsystem.

[0033] figure 1 It is a touch screen display operation display interface, using HMI touch screen and 3DVR LCD screen. The input end of the HMI touch screen is connected to the output end of the PLC, and the input end of the HMI LCD screen is connected to the output end of the central controller. It is installed in the ground control center for The movement process of the three machines is always displayed, and the touch screen can control the start and stop of the system and set the initia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com