Array substrate and preparation method thereof

A technology of an array substrate and a substrate layer, applied in the field of array substrates and their preparation, can solve problems such as multi-mask processes, and achieve the effects of saving mask processes and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] Please refer to the drawings in the accompanying drawings, wherein the same component symbols represent the same components, the following description is based on the specific embodiment of the invention shown, and it should not be considered as limiting the invention to other specific embodiments not described in detail herein. Example. The word "embodiment" as used in this specification means an example, instance or illustration. Furthermore, as used in this specification and the appended claims, the article "a" or "an" may generally be construed as "one or more" unless specified otherwise or clear from the context in the singular.

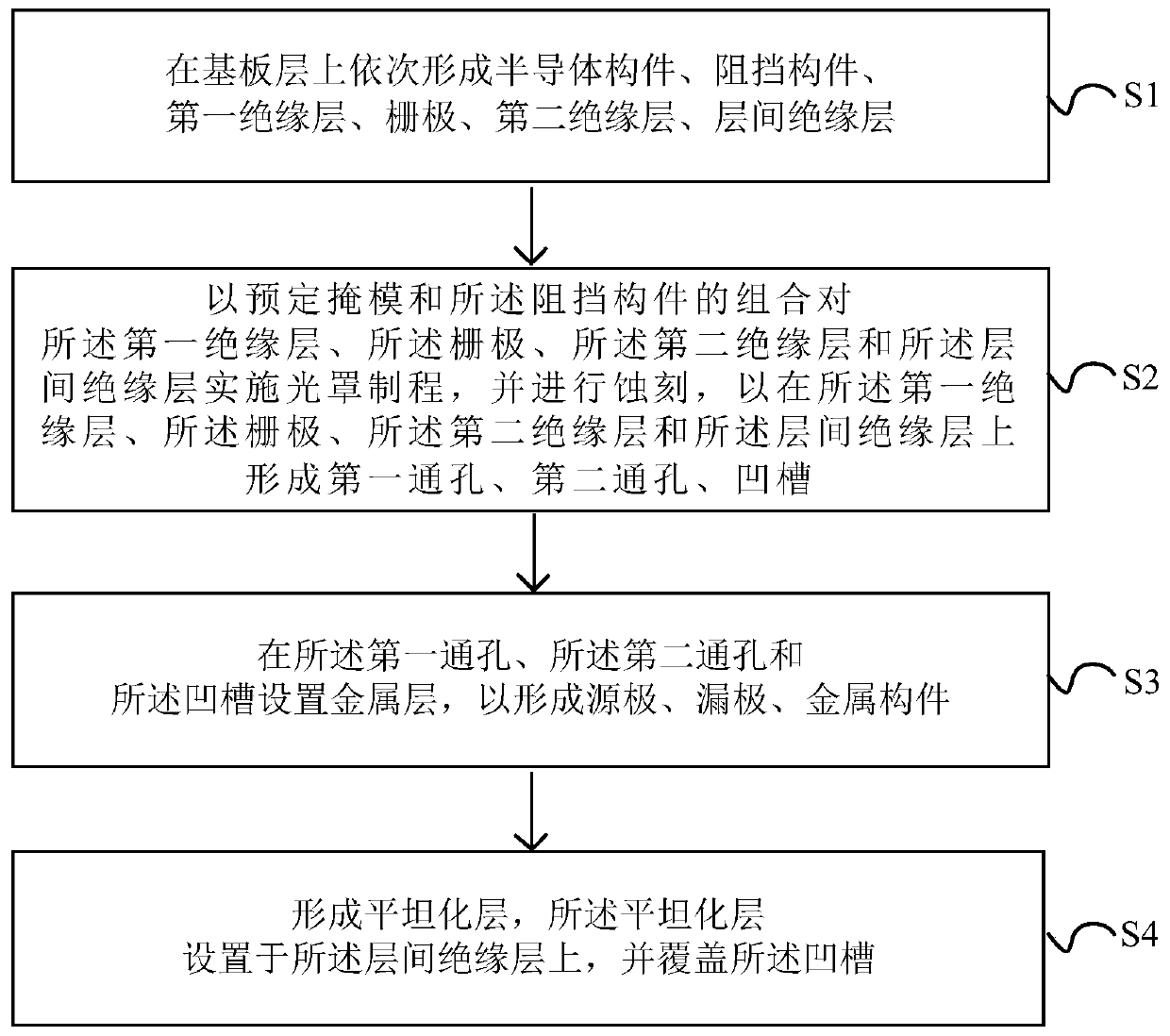

[0062] Such as figure 1 As shown, the embodiment of the present invention provides a method for preparing an array substrate, the method comprising:

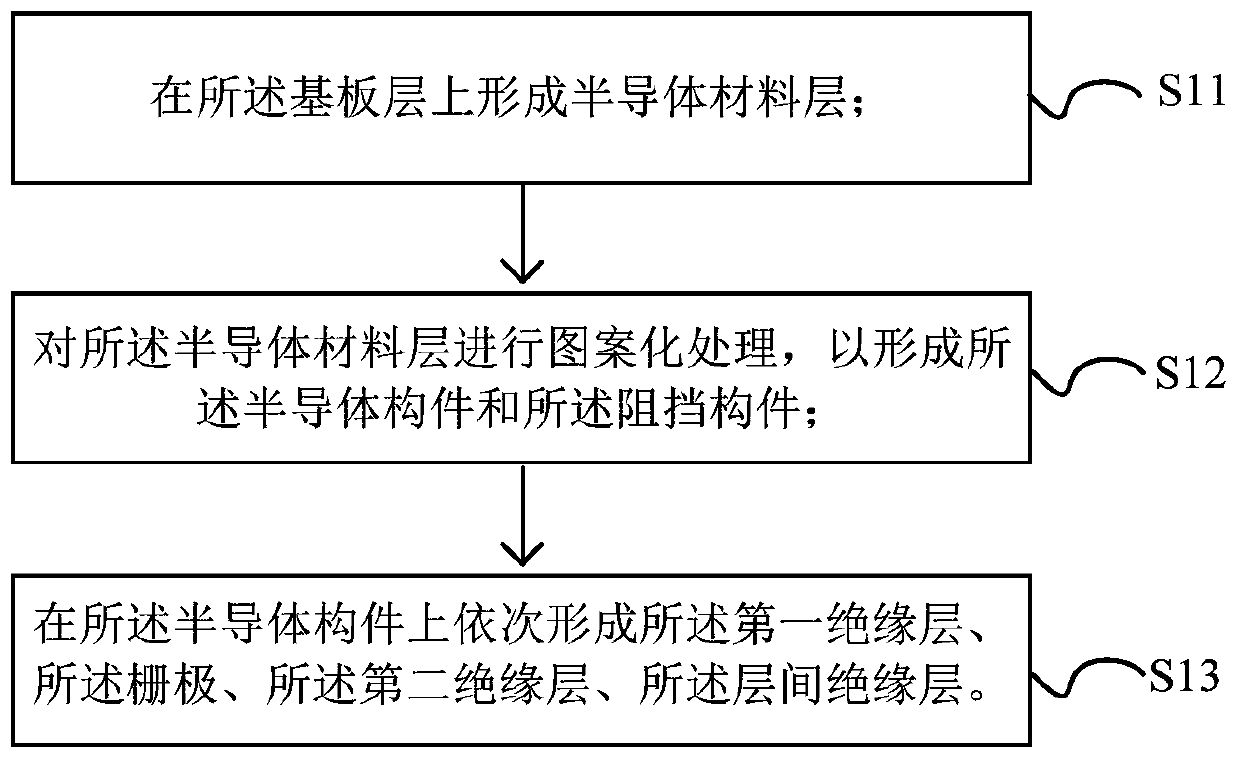

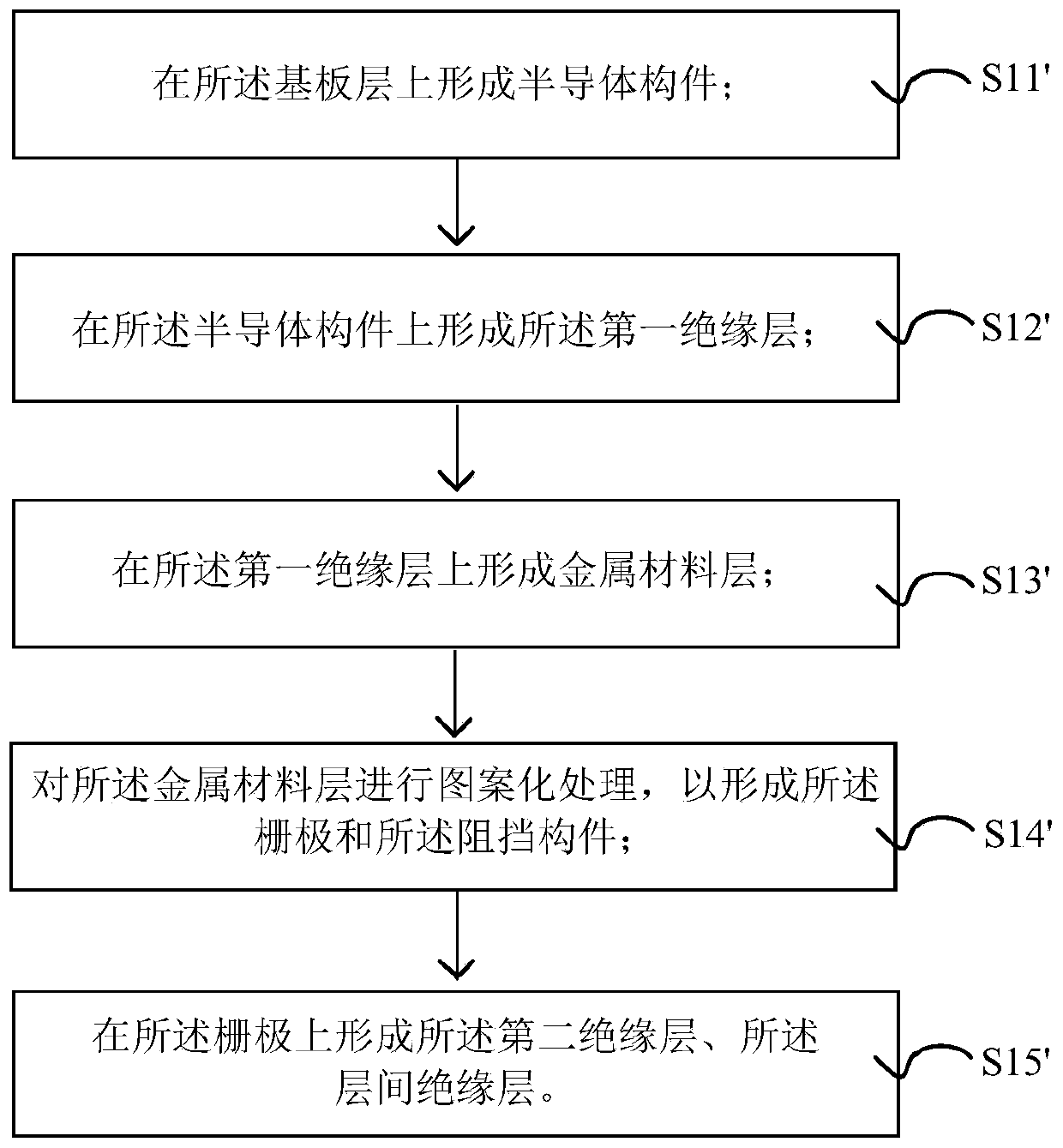

[0063] Step S1: sequentially forming a semiconductor component, a barrier component, a first insulating layer, a gate, a second insulating layer, and an interlayer insulating layer on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com