Display substrate and display device

A technology for display substrates and display devices, which is applied in semiconductor devices, electrical components, circuits, etc., and can solve problems such as affecting display effects, missed detection of bright spots, and ET twill

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

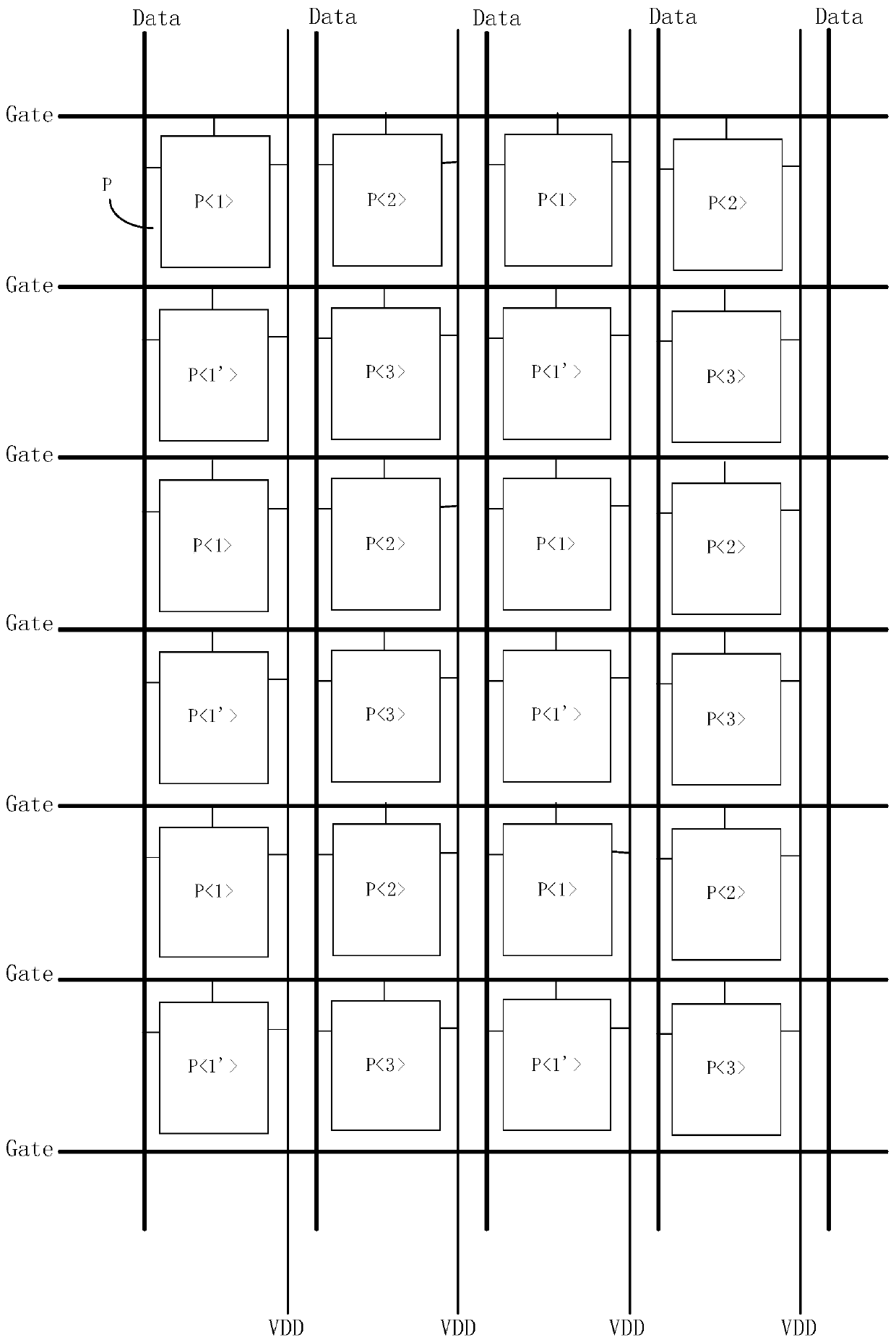

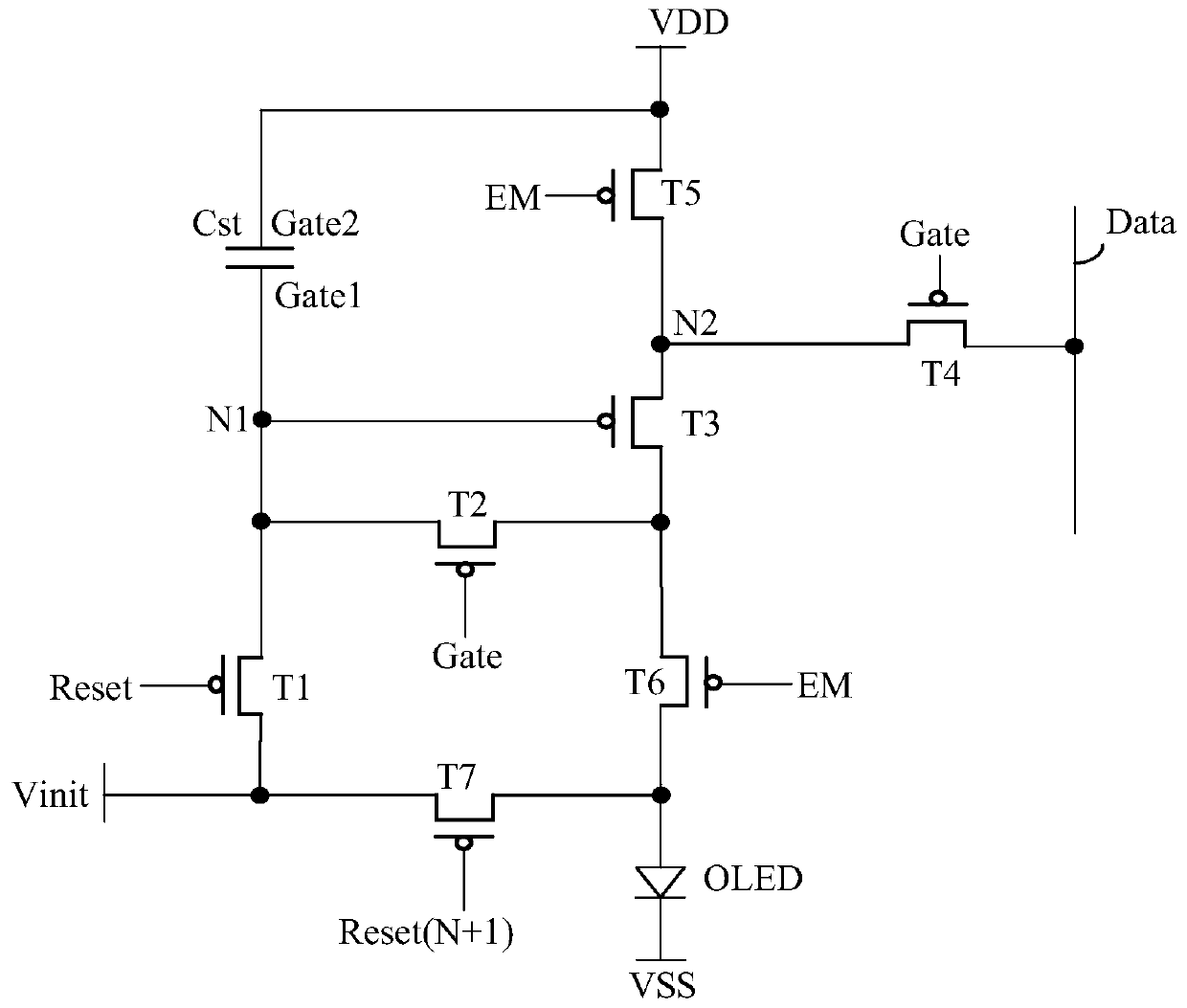

[0084] Image 6 It is a schematic structural diagram of a first sub-pixel in each pixel unit in Embodiment 1 of the present disclosure, Figure 7 It is a schematic structural diagram of another first sub-pixel in each pixel unit in Embodiment 1 of the present disclosure. In order to effectively solve the technical problems in the comparative embodiment, Embodiment 1 of the present disclosure provides a comparison with the foregoing comparative embodiment. Different settings of the film layer structure of the first sub-pixel, specifically, the difference between Embodiment 1 of the present disclosure and the foregoing comparative embodiment is that in Embodiment 1 of the present disclosure, as figure 1 , figure 2 , Image 6 with Figure 7 As shown, for each first sub-pixel (such as P or P), the first sub-pixel (such as P or P) also includes a setting corresponding to the through hole h In the first sub-pixel (such as P or P), the orthographic projection of the second plate...

Embodiment 2

[0095] Figure 8 It is a schematic structural diagram of a first sub-pixel in each pixel unit in Embodiment 2 of the present disclosure, Figure 9It is another schematic structural diagram of a first sub-pixel in each pixel unit in Embodiment 2 of the present disclosure. In order to effectively solve the technical problems in the comparative embodiment, Embodiment 2 of the present disclosure provides Different setting of the film layer structure of the first sub-pixel, specifically, the difference between the second embodiment of the present disclosure and the aforementioned comparative embodiment is that in the second embodiment of the present disclosure, for each pixel unit, such as figure 1 , figure 2 with Figure 8 As shown, in a first sub-pixel P of the pixel unit, the anode AND of the light-emitting device OLED is located on the side of the second plate Gate2 away from the substrate, and the anode AND is on the first plate Gate1 The orthographic projection of covers ...

Embodiment 3

[0108] Figure 10 It is a schematic structural diagram of a first sub-pixel in each pixel unit in Embodiment 3 of the present disclosure, Figure 11 It is a schematic structural diagram of another first sub-pixel in each pixel unit in Embodiment 3 of the present disclosure. In order to effectively solve the technical problems in the comparative embodiment, Embodiment 3 of the present disclosure provides a comparison with the foregoing comparative embodiment. Different setting of the film layer structure of the first sub-pixel, specifically, the difference between the third embodiment of the present disclosure and the aforementioned comparative example is: in the third embodiment of the present disclosure, as figure 1 , figure 2 , Figure 10 with Figure 11 As shown, for each first sub-pixel (such as P or P), in the first sub-pixel (such as P or P), the light emitting device OLED The anode AND is located on the side of the second plate Gate2 away from the substrate, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com