High multi-layer board layer detection fool-proof method

A separate detection, high-level multi-layer technology, applied in the field of high-level multi-layer board level detection and fool prevention, it can solve the problems of error-prone, misplaced adjacent layers, inability to identify, and difficult to distinguish and identify, so as to reduce abnormal leakage. , The effect of avoiding the outflow of bad products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

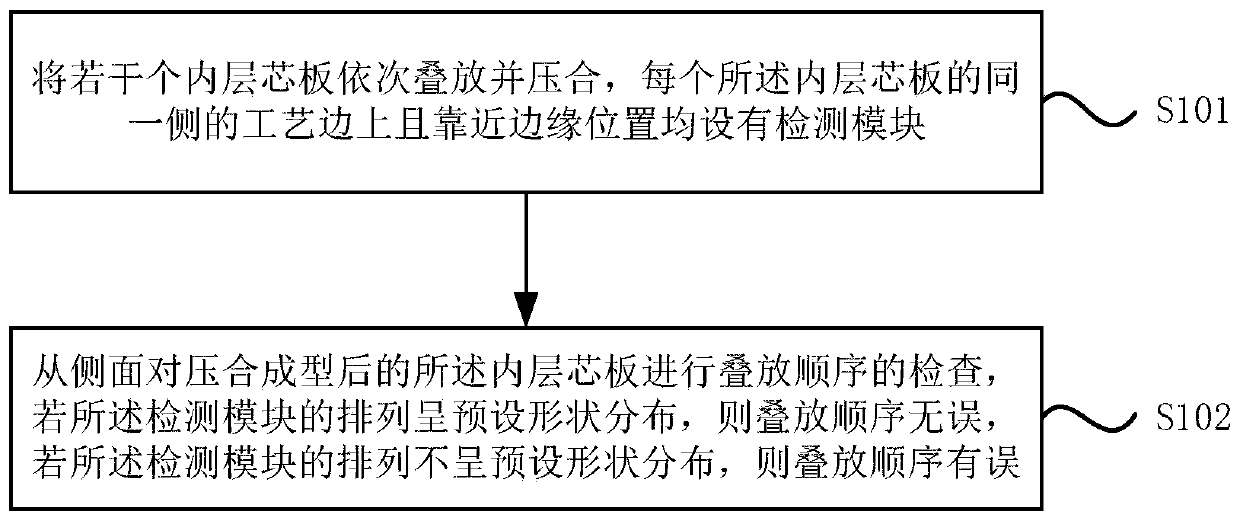

[0026] Please refer to the attached figure 1 , is a schematic flowchart of a layer-specific detection and anti-fooling method for a high-multilayer board provided in Embodiment 1 of the present invention. The method specifically includes the following steps:

[0027] S101. Stack and press several inner core boards in sequence, and each of the inner core boards is provided with a detection module on the same side of the process edge and near the edge.

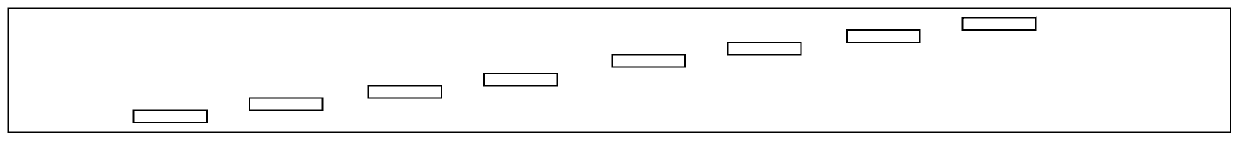

[0028] S102. Check the stacking sequence of the laminated inner core board from the side. If the detection modules are arranged in a preset shape, the stacking sequence is correct. If the detection modules are arranged incorrectly If they are distributed in a preset shape, the stacking order is wrong.

[0029] It should be noted that the preset shape can be a slanted line or any other shape, as long as it can identify whether the core board is misplaced.

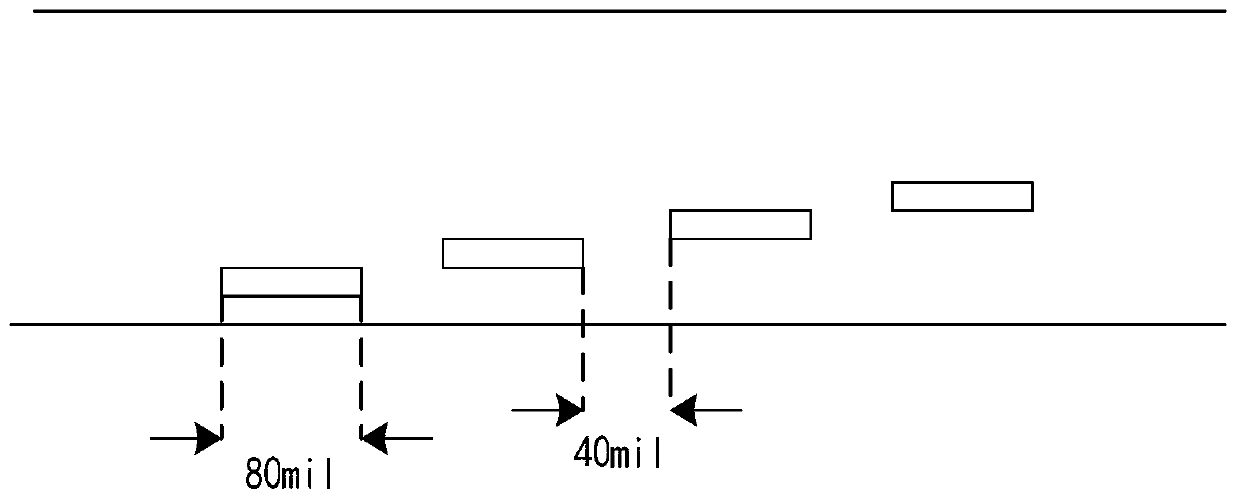

[0030] Preferably, before the step of stacking and pressing several in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com