A method for filtering radioactive waste incineration flue gas

A radioactive waste and incineration flue gas technology, which is applied in the field of radioactive waste incineration and incineration flue gas dust removal, can solve the problems such as difficulty in filter ash removal, achieve easy ash removal and filter bag replacement, low pollution degree, and good filtering effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

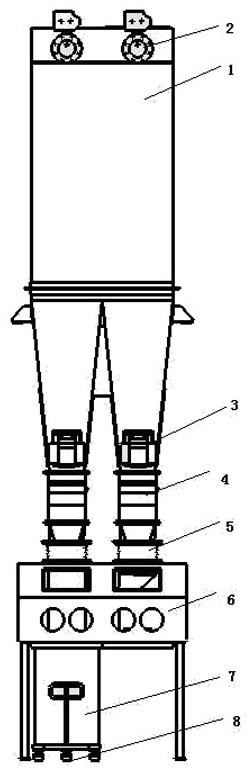

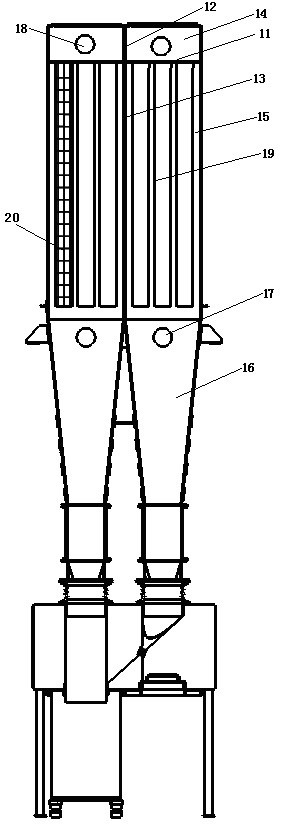

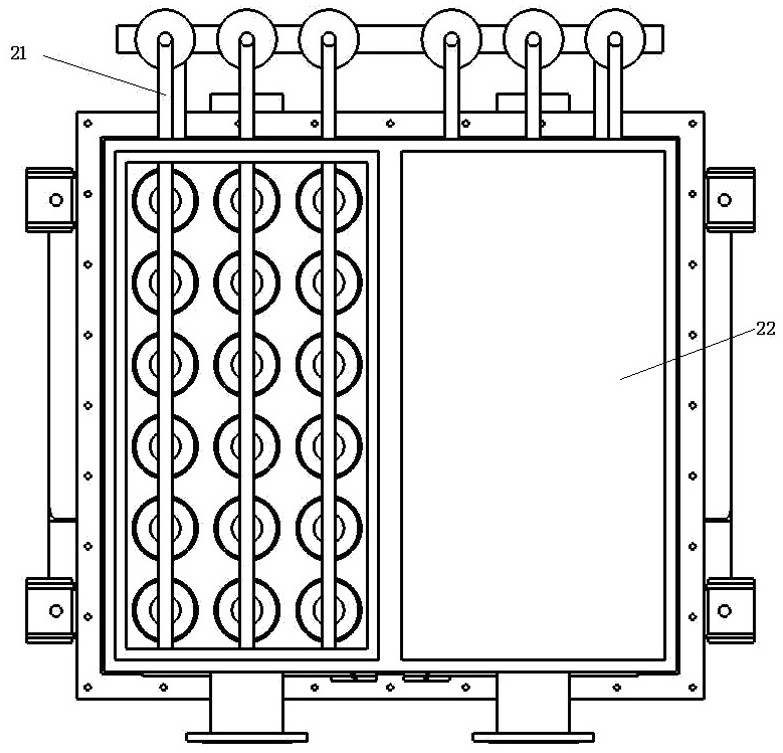

[0069] As shown in the figure, the bag filter of this embodiment includes a box body 1, a partition assembly, a filter unit, and an ash removal unit. Wherein, the partition assembly is arranged in the box body 1, and a dust filter chamber is formed between the partition board assembly and the inner wall of the box body 1, and there are two dust filter chambers and two filter units respectively. In this embodiment, the partition assembly is composed of an upper partition 12 and a lower partition 13 , the upper partition 12 is located above the flower board 11 , and the lower partition 13 is located below the flower board 11 .

[0070] The filter unit includes a flower plate 11, a cage 20, a filter bag 19, an ash hopper 16, an air inlet 17, an electric heating element 23, a wall vibrator 3, a heavy hammer type flap ash removal valve 4, a connecting hose 5, maintenance Door 22, air outlet hole 18, air outlet valve 2, spray pipe 21. In this embodiment, the connecting hose 5 is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com