Compact quantitative glue application device

A glue application device and compact technology, which can be applied to the device, coating, pretreatment surface, etc. for applying liquid to the surface, which can solve the problems of uneven glue supply, inability to guarantee glue, and low work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

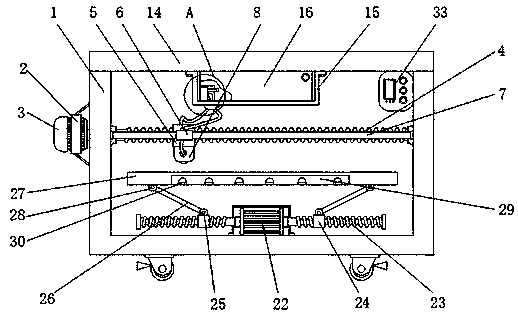

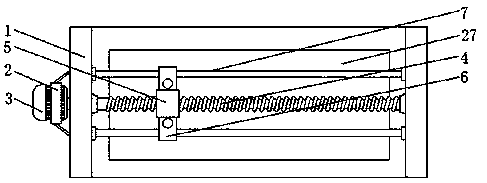

[0031] Embodiment one, with reference to Figure 1-2 , a kind of compact quantitative gluing device, by installing a rotating motor 3 on the inside of the mounting frame 2 welded on the outside of the gluing frame 1, the output shaft of the rotating motor 3 runs through the gluing frame 1 and is fixedly connected with the first screw mandrel 4, The first screw mandrel 4 is movably connected with the shaft seat installed on both sides of the inside of the glue spreader 1 to stabilize the output position of the first screw mandrel 4, and the first threaded sleeve 5 is screwed on the outer side of the first screw mandrel 4 again, the first The two connecting blocks 6 welded on both sides of the threaded sleeve 5 are movably connected with the two sliding rods 7 inserted into the inner side of the gluing frame 1, so that the first threaded sleeve 5 can reciprocate and linearly move smoothly on the first screw rod 4 Do glue work.

Embodiment 2

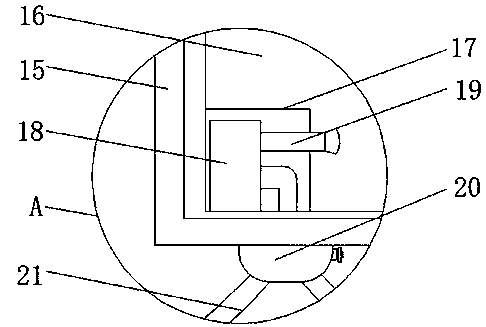

[0032] Embodiment two, refer to figure 1 , image 3 and Figure 4 , by installing the rubber storage cylinder 16 inside the fixed frame 15 installed by bolts at the bottom of the top plate 14 installed on the top of the glue application frame 1, the rubber pump 18 is installed in the installation chamber 17 provided on the inner side of the bottom of the rubber storage cylinder 16, and the rubber pump 18 The upper part is respectively connected with the feed pipe 19 and the control chamber 20, the feed pipe 19 runs through the installation chamber 17 and extends into the glue storage cylinder 16, the side of the control chamber 20 is provided with a flow valve, the flow valve can be used to control the flow rate of the glue, and The other end of the discharge pipe 21 connected to the bottom of the control chamber 20 is connected to the stick shaft tube 9, and the inside of the stick shaft tube 9 is movably installed with a glue spreader 10, and the stick shaft tube 9 is a hol...

Embodiment 3

[0033] Embodiment three, refer to figure 1 and Figure 5 , the double-axis motor 22 is installed through the inner side of the bottom of the gluing frame 1, the second threaded mandrel 23 fixedly connected on the output shaft of the double-axis motor 22 is threaded to connect the second threaded sleeve 24, and the top of the second threaded sleeve 24 is welded The first mounting plate 25 is connected to the connecting rod 26 through the rotation of the rotating shaft, and the other end of the connecting rod 26 is movable to install the gluing platform 27, and the installation groove 29 provided on the inner side of the gluing platform 27 is provided at the bottom to install the heating bulb 30, which can be opened at the top of the gluing platform 27. The drying hole 32 can dry the glue on the plank from time to time, so that the drying step and the gluing work are carried out synchronously, which improves the work efficiency. The frictional force of the rubber platform 27 av...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com