An intelligent hot runner temperature control method and temperature control system

An intelligent heat flow and temperature control system technology, applied in the field of temperature control systems, can solve problems such as complicated wiring, inconvenient troubleshooting, and large control boxes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

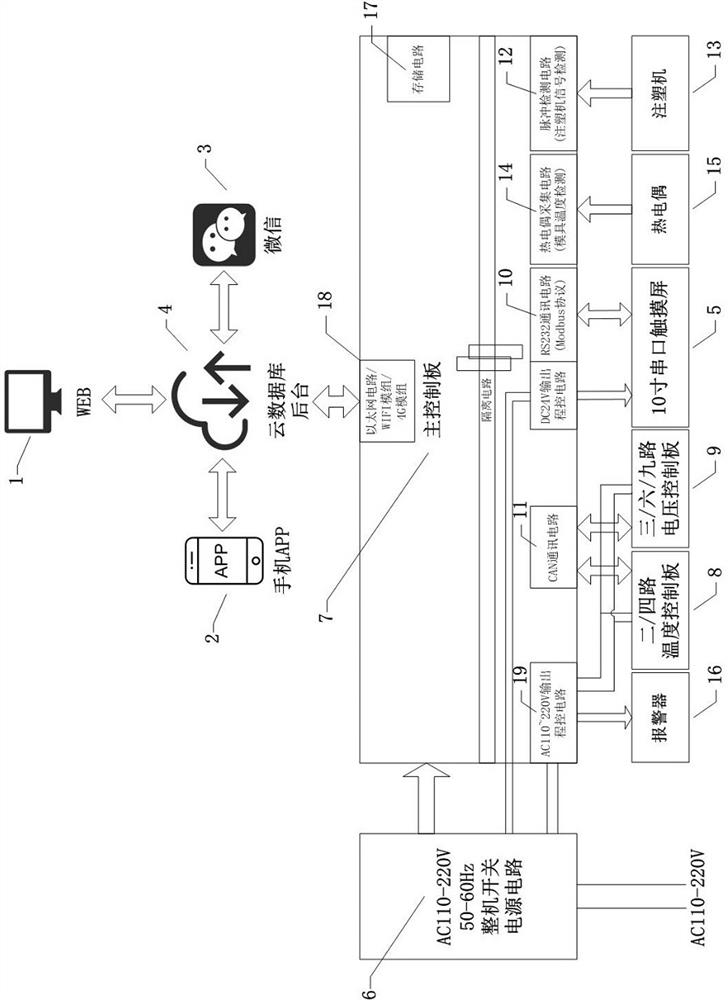

[0041] as attached figure 1 As shown, the intelligent hot runner temperature control system includes a power supply circuit 6, which can obtain the power required by the system from the mains, preferably an AC110-220V switching power supply circuit for the whole machine.

[0042] The main control board 7 obtains power from the power supply circuit 6 to perform control.

[0043] Different from the traditional nixie tube display, this system is equipped with a touch screen 5. In order to control better, the touch screen is preferably a 10-inch serial port touch screen. The touch screen can be selected as China Taiwan Weilun touch screen.

[0044] An isolated RS232 communication line is used between the main control board 7 and the touch screen 5, and data communication is performed through the Modbus communication protocol.

[0045] The main control board 7 uses an isolated CAN communication line to communicate with the temperature control board 8 and the voltage control board...

Embodiment 2

[0049] On the basis of the first embodiment, the main control board 7 of the system is provided with a pulse detection circuit 12, and the pulse detection circuit is used to detect whether there is a pulse of the injection molding machine 13 to determine whether the injection molding machine is offline.

[0050] The main control board 7 is also provided with a thermocouple acquisition circuit 14, and the thermocouple acquisition circuit collects the temperature of the mold through the thermocouple 15 to monitor the production environment, thereby realizing safe production.

[0051] The main control board 7 is also provided with a first program-controlled circuit 19 connected to an external alarm 16, which is used to warn the on-site production operators of dangerous signals (such as abnormal mold temperature, offline injection molding machine, etc.). The main control board 7 is connected to the temperature control board and the voltage control board through the first program co...

Embodiment 3

[0056] On the basis of the above two embodiments, the main control board can perform associated linkage control of each circuit according to the configuration of the touch screen by analyzing the information of each temperature / voltage control board. At present, there is no prior art about linkage control for controlling the temperature of molds in a large range (such as higher than 4 channels). Even on the same temperature control board, such as the two / four-way temperature control board mentioned above, multiple temperature controls are integrated into one control board, which is still an independent control in essence.

[0057] The specific method of temperature control is as follows:

[0058] After starting up, the main control board controls the storage circuit to read the system configuration of the default / last shutdown;

[0059] The main control board detects the number of circuits of the temperature control board and the voltage control board connected to the main co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com