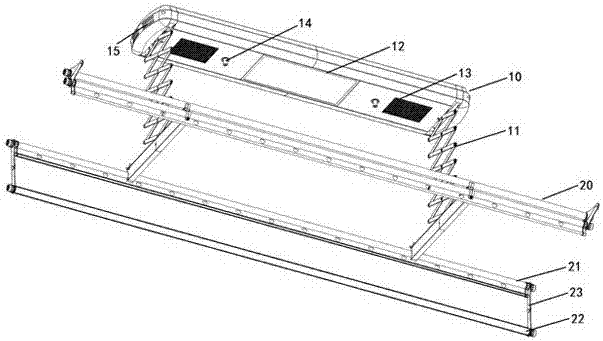

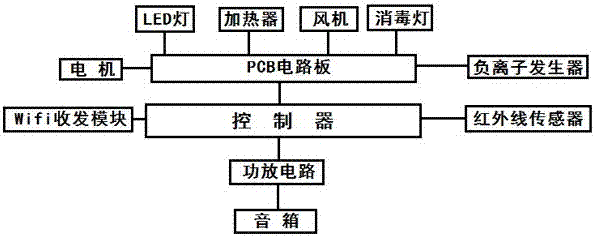

Multifunctional smart clothes dryer

A clothes dryer and multi-functional technology, which is applied in the field of multi-functional intelligent clothes dryers, can solve the problems of not being able to meet the user's personalization and interaction needs, single function, etc., and achieve the effect of excellent corrosion resistance and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

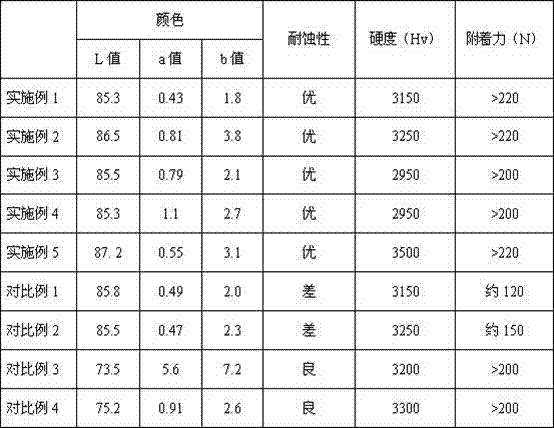

Embodiment 1

[0023] In this embodiment, a Ni metal layer, a barrier layer and a wear-resistant surface layer are sequentially formed on the surface of the aluminum alloy. First, a Ni metal layer was deposited by multi-arc ion plating (Ni target, background vacuum degree 10 -3 Pa, the target current is 25A, the deposition temperature is above 250°C, the bias voltage is 200V, the pressure of argon is 0.1 Pa), and the thickness is controlled at 50~60nm. Deposition by reactive magnetron sputtering on the Ni metal layer (Ni target, background vacuum degree 10 -3 Pa, deposition temperature 300°C, Ar 200sccm, N 2 10 sccm, O 2 5 sccm, bias voltage 200V, current 20 A) a barrier layer with a thickness of 0.2 μm, the content of N in the obtained barrier layer was 1.1wt%, and the content of O was 0.65wt%. Deposition by reactive magnetron sputtering on the barrier layer (background vacuum degree 10 -3 Pa, deposition temperature 300°C, Ar200sccm, N 2 20 sccm, O 2 20sccm, bias voltage 200V, cur...

Embodiment 2

[0025] In this embodiment, a Ni metal layer, a barrier layer and a wear-resistant surface layer are sequentially formed on the surface of the aluminum alloy. First, a Ni metal layer was deposited by multi-arc ion plating (Ni target, background vacuum degree 10 -3 Pa, the target current is 25A, the deposition temperature is above 250°C, the bias voltage is 200V, the pressure of argon is 0.1 Pa), and the thickness is controlled at about 300nm. Deposition by reactive magnetron sputtering on the Ni metal layer (Ni target, background vacuum degree 10 -3 Pa, deposition temperature 300°C, Ar 200sccm, N 2 10 sccm, O 2 5 sccm, bias voltage 200V, current 20 A) a barrier layer with a thickness of 0.5 μm, the content of N in the obtained barrier layer was 1.1wt%, and the content of O was 0.65wt%. Deposition by reactive magnetron sputtering on the barrier layer (background vacuum degree 10 -3 Pa, deposition temperature 300°C, Ar200sccm, N 2 20 sccm, O 2 20sccm, bias voltage 200V,...

Embodiment 3

[0027] In this embodiment, a Ni metal layer, a barrier layer and a wear-resistant surface layer are sequentially formed on the surface of the aluminum alloy. First, a Ni metal layer was deposited by multi-arc ion plating (Ni target, background vacuum degree 10 -3 Pa, the target current is 25A, the deposition temperature is above 250°C, the bias voltage is 200V, the pressure of argon is 0.1 Pa), and the thickness is controlled at 50~60nm. Deposition by reactive magnetron sputtering on the Ni metal layer (Ni target, background vacuum degree 10 -3 Pa, deposition temperature 300°C, Ar 200sccm, N 2 10sccm, bias voltage 200V, current 20 A) a barrier layer with a thickness of 0.2 μm, and the content of N in the obtained barrier layer was 1.2wt%. Deposition by reactive magnetron sputtering on the barrier layer (background vacuum degree 10 -3 Pa, deposition temperature 300°C, Ar 200sccm, N 2 20sccm, bias voltage 200V, current 20 A) has a wear-resistant surface layer with a thickn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com