Forming mould for ecological wood external wall panel with textures

A technology for hanging wall panels and forming molds is applied in the field of extrusion forming molds, which can solve the problems of low forming quality and high mold pressure ratio requirements, and achieve good texture effect, good product forming effect, and good practical use and promotion. effect of value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

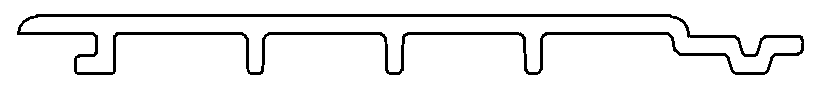

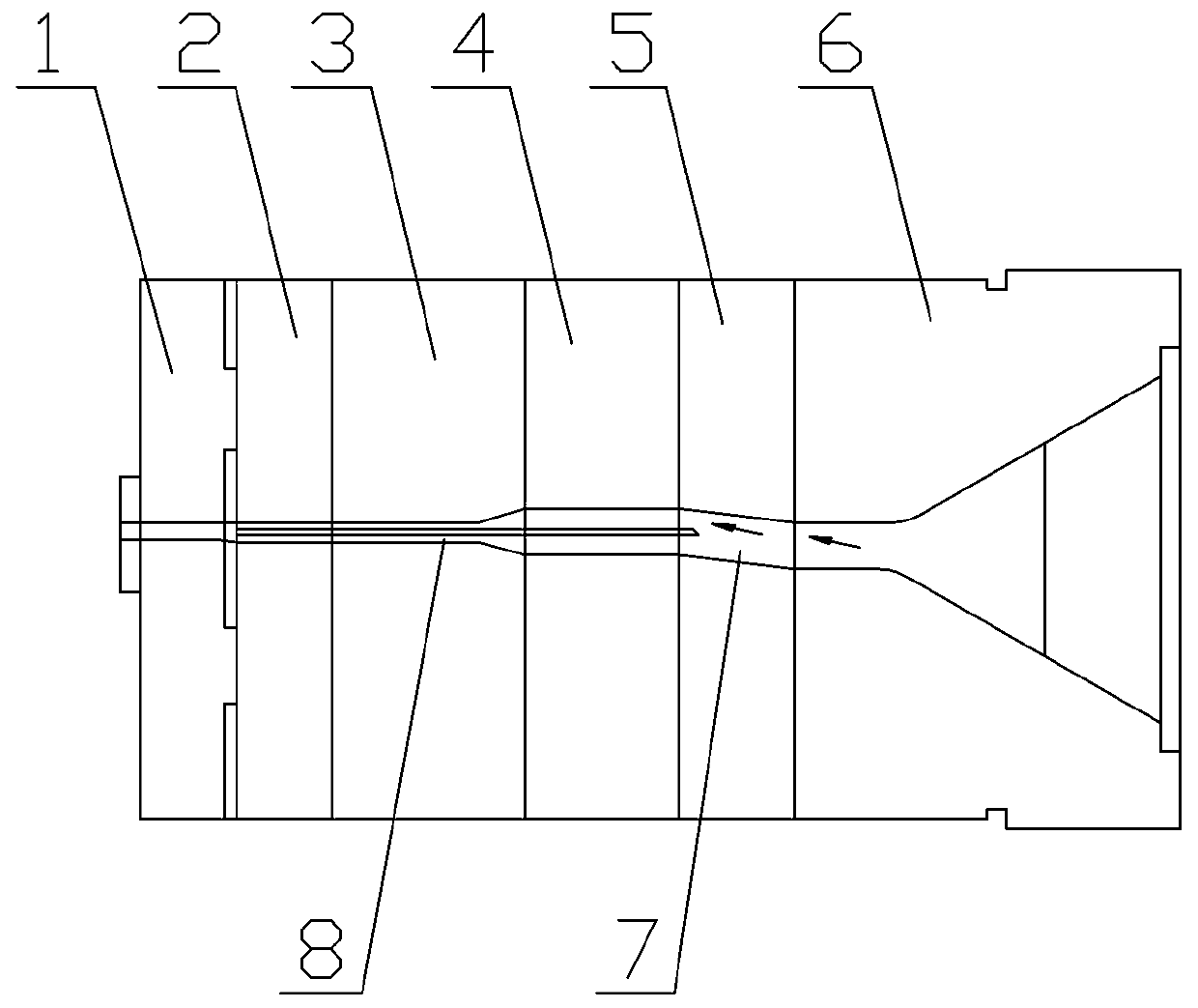

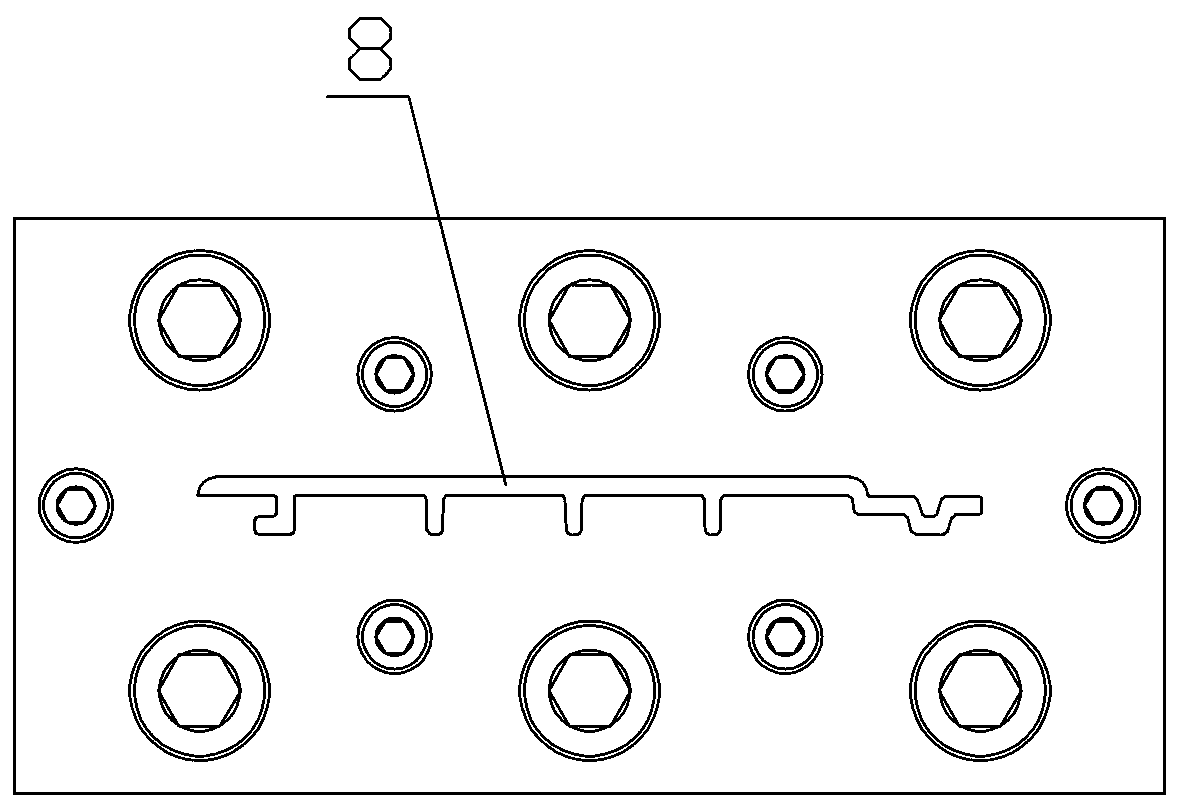

[0011] see figure 2 , image 3 , the present invention is a kind of eco-wood self-contained texture exterior wall panel forming mold, comprising mold body 6, transition plate 5, support plate 4, die one 3, die two 2 and water jacket 1, support plate, mouth Die 1 and Die 2 have molding cavities 8 inside, and the entrance of the mold body is processed into a circular arc shape with a depth of 40mm by turning; the central axis of the molding cavity and the material flow channel in the mold body The central axis is in a staggered arrangement, and the material flow channel in the transition plate is an inclined flow channel 7, and the inclined flow channel in the transition plate connects the molding cavity and the material flow channel in the mold body.

[0012] The present invention has the following beneficial effects: because the depth of the mold body inlet is set to 40mm, the material flow pressure is distributed for the first time at the material flow inlet, and then throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com