Oil path system used for double-needle-bar warp knitting machine

A double-needle bed warp knitting machine and oil circuit system technology, applied in knitting, textiles and papermaking, etc., can solve problems such as cloth surface weaving defects, accelerated wear of connecting rod frame groups, deformation of knitting elements, etc., and achieve lubricating effect and thermal Improvement of exchange efficiency, improvement of heat exchange performance, and improvement of lubricating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

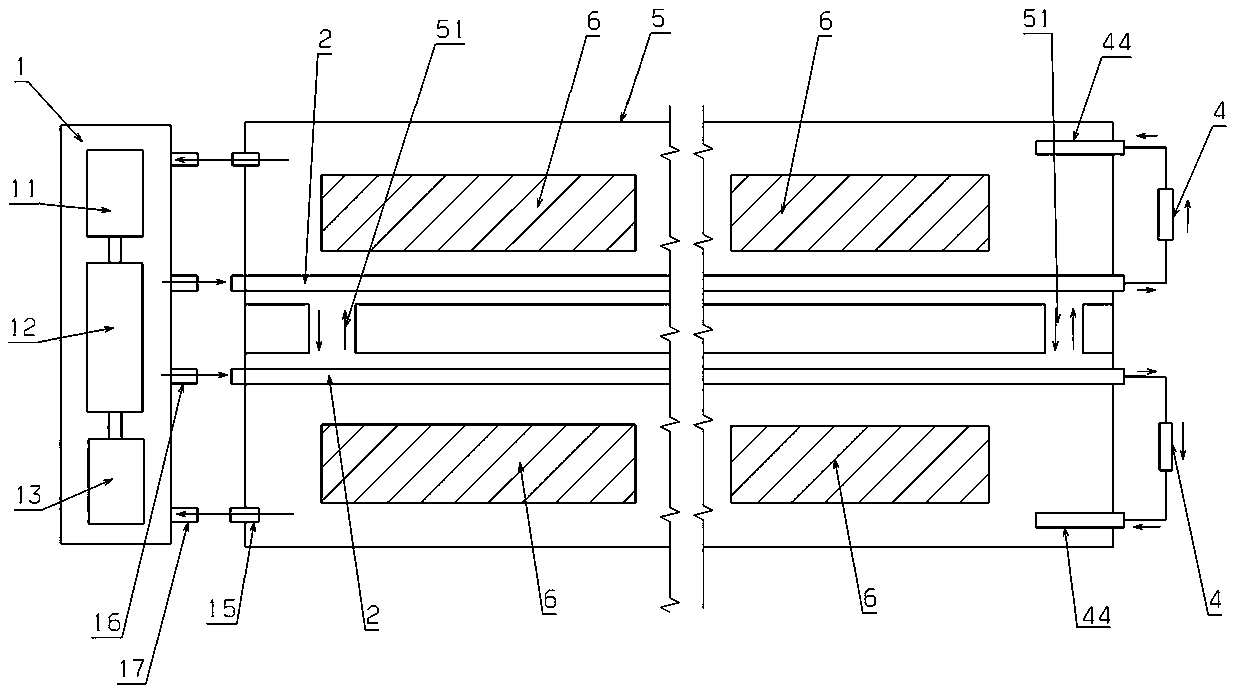

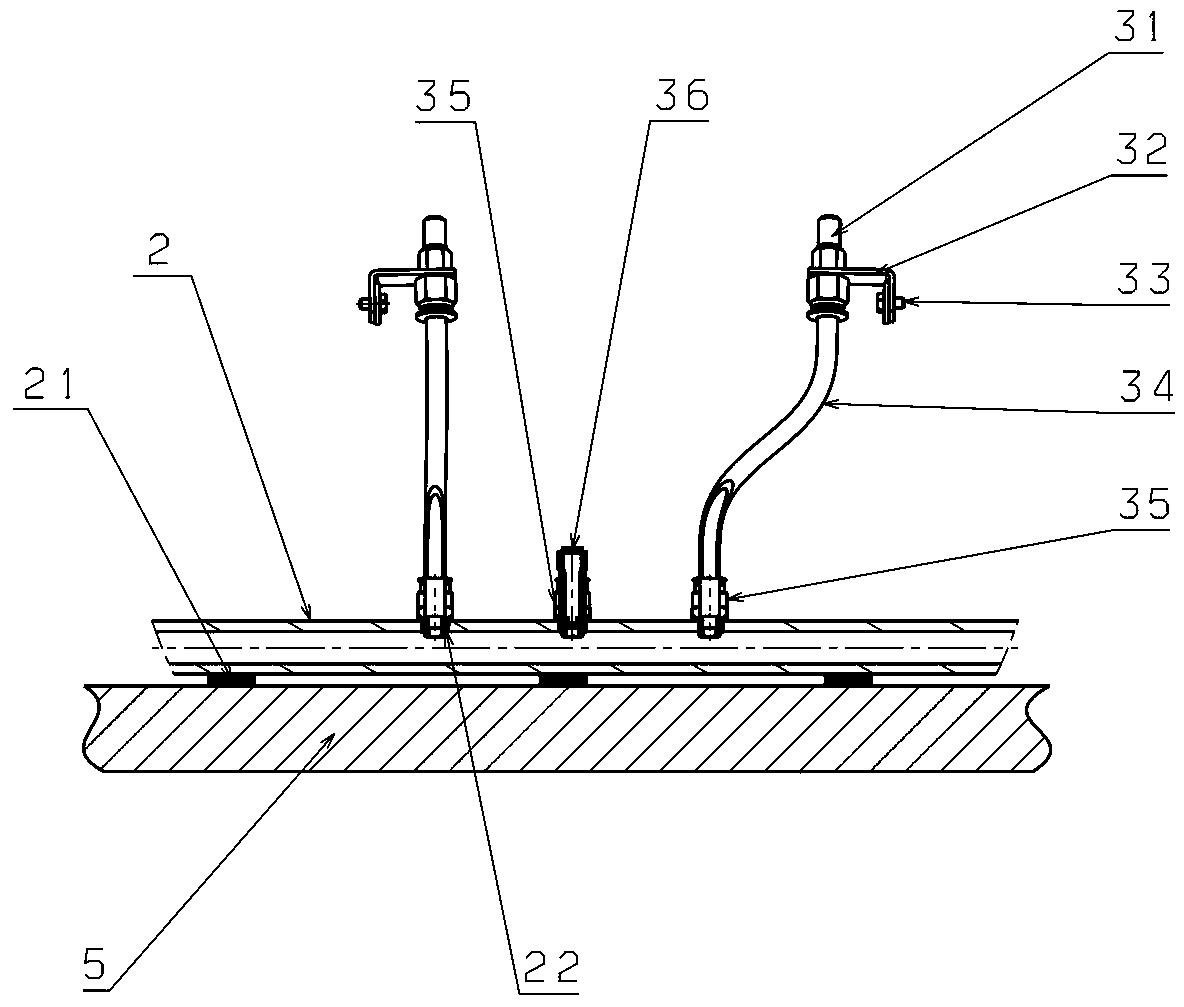

[0020] Such as figure 1 and 2 As shown: this embodiment is an oil circuit system for a double-needle bed warp knitting machine, including a heating pump oil device 1 and an oil delivery pipe 2, the oil delivery port 16 of the heating pump oil device 1 communicates with the oil delivery pipe 2, and the heating pump oil The oil suction port 17 of the device 1 communicates with the oil outlet hole 15 on the bed 5, the oil delivery pipe 2 is installed inside the bed 5, and a plurality of threaded holes 22 are formed on the pipe body of the oil delivery pipe 2, and the threaded holes 22 are detachably connected with Fuel injection system or plug 36.

[0021] In this embodiment, an oil delivery pipe 2 is respectively installed in the front cabin and the rear cabin inside the bed 5; A fixed connection structure is formed; in this design, both ends of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com