Recovery device and recovery method for waste heat of raw coke oven gas of coking plant

A waste heat recovery device and waste heat recovery technology, which are applied in the discharge device of dry distillation gas, the steam generation method using heat carrier, the steam generation method, etc., can solve the problems of small demand, rupture of the inner wall of the riser, and limited application occasions. , to achieve the effect of huge cost, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

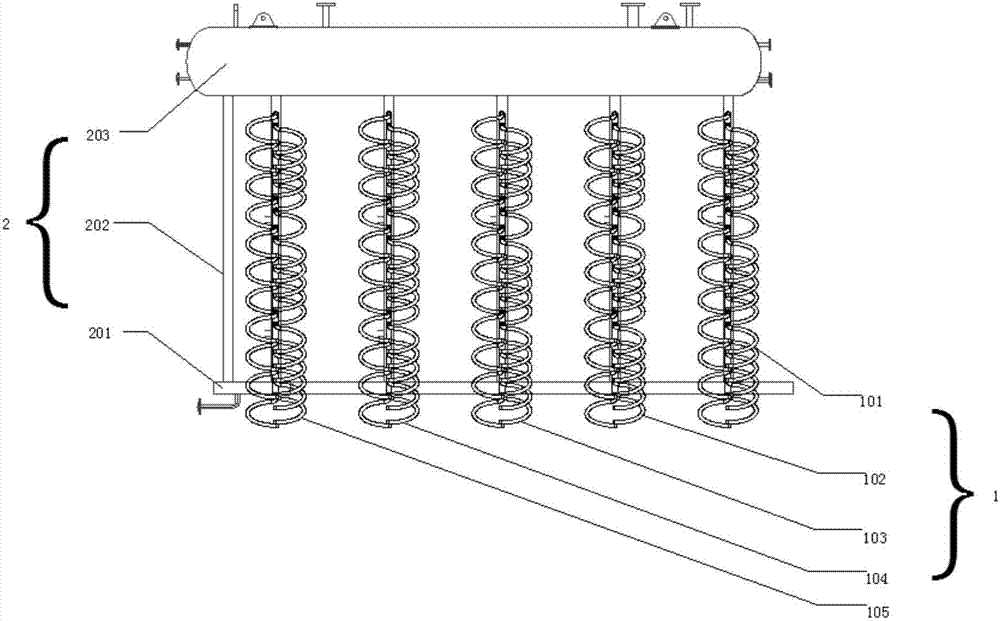

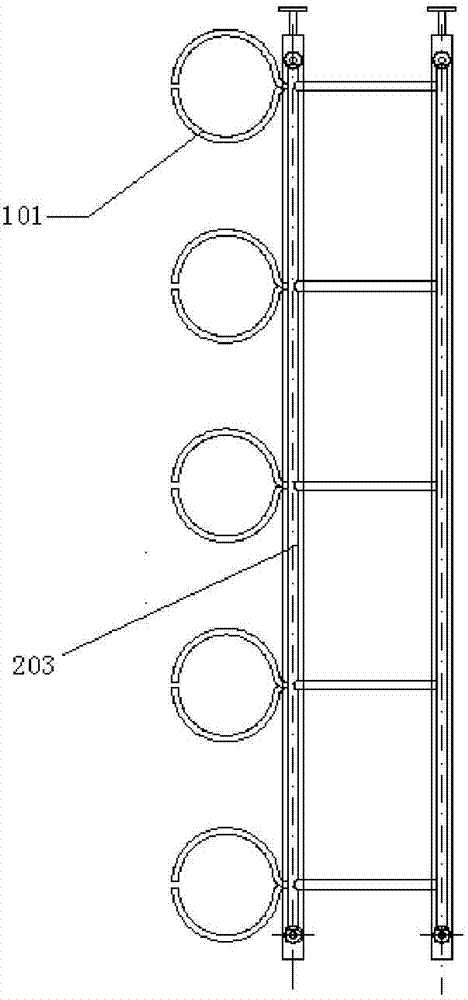

[0060] Please refer to figure 1 , figure 2 as well as image 3 , a coking plant raw gas waste heat recovery device provided in an embodiment of the present invention includes a heat conduction device 1 and a steam device 2;

[0061] Wherein, the heat conduction device 1 includes heat conduction pipes 101, heat conduction pipes 102, heat conduction pipes 103, heat conduction pipes 104, and heat conduction pipes 105, etc., which are arranged in parallel;

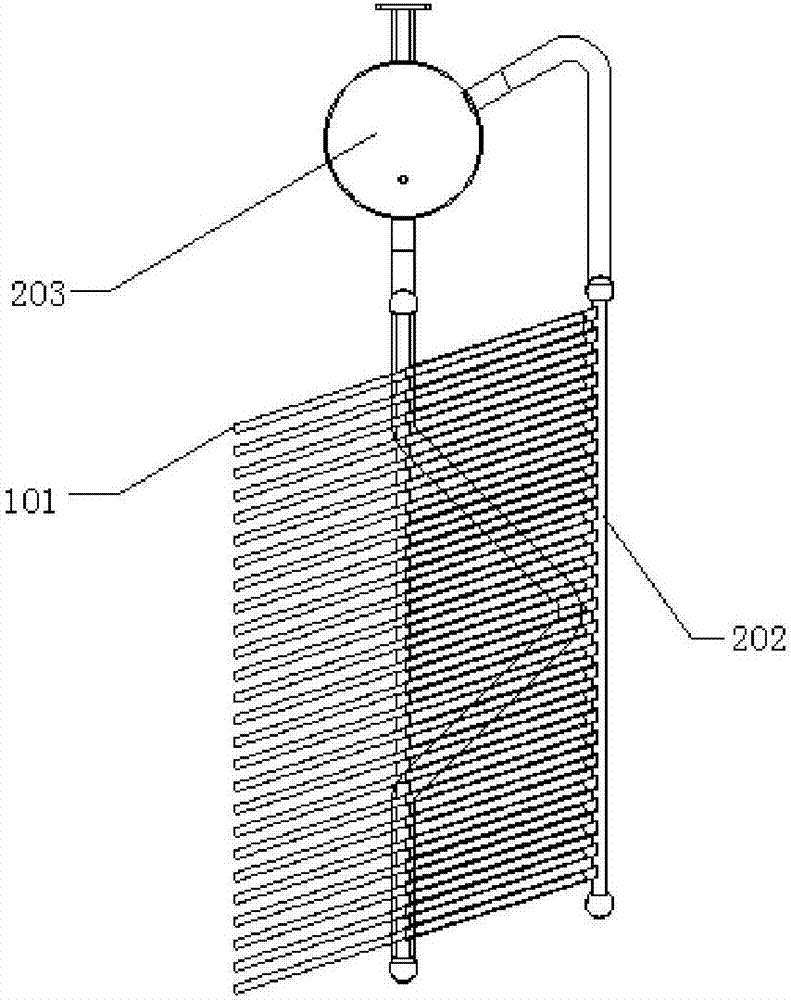

[0062] The steam device 2 includes a water pipe 201, a steam pipe 202 and a steam drum 203;

[0063] Wherein, the heat pipe 101 has a spiral structure and is connected with the steam pipe 202 .

[0064] Further, the heat pipe 101 is a hollow structure, and further includes a pipe wall and a liquid-absorbing core, and the absorbent core is provided with metal sodium as a heat transfer working medium.

[0065] Please refer to Figure 4 as well as Figure 5 , in the coking plant raw gas waste heat recovery device of the pr...

Embodiment 2

[0068] Please refer to figure 1 , figure 2 , image 3 , Figure 4 as well as Figure 5 A method for recovering waste heat from raw gas in a coking plant provided by an embodiment of the present invention includes the following steps:

[0069] Raw coal gas is introduced from the lower part of the riser 3, the heat receiving section of the heat transfer pipe 101 absorbs heat in the riser 3, the metal sodium working fluid in the heat transfer pipe 101 gradually melts, and forms sodium vapor in the steam channel area at the center of the heat transfer pipe 101 , as the evaporation continues, after the accumulation of steam in the central area of the evaporation section reaches a certain amount, a continuous flow of steam is gradually established; The end of the heat release section makes all sections of the heat pipe 101 reach the state of continuous steam flow, and the heat pipe 101 enters the working state. With the passage of time and the continuous transfer of heat, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com