Optical adhesive and optical sensor module

An optical sensor and adhesive technology, which is used in instruments, character and pattern recognition, printing and image acquisition, etc., can solve the problem that the performance of optical sensor modules needs to be improved, and achieves small differences in refractive index changes, improved performance, and uniformity. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] As mentioned in the background, existing optical sensor modules have poor performance.

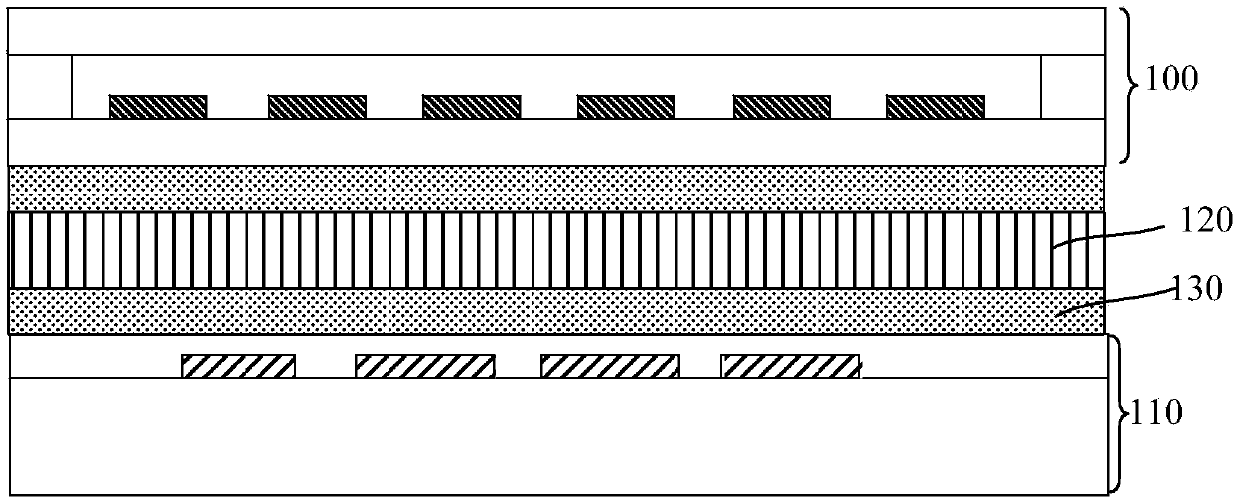

[0034] An optical sensor module, reference figure 1 , comprising: a self-luminous display panel 100; an optical sensor 110; a light collimation layer 120 between the self-luminous display panel 100 and the optical sensor 110; a light collimation layer between the light collimation layer 120 and the optical sensor 110 120 and the adhesive layer 130 between the self-luminous display panel 100 .

[0035] The material of the adhesive layer 130 is optical glue.

[0036] The adhesive layer 130 bonds the self-luminous display panel 100 and the light-collimating layer 120, and bonds the optical sensor 110 and the light-collimating layer 120, avoiding an air layer between the self-luminous display panel 100 and the optical sensor 110, The light scattering phenomenon caused by the air layer is avoided, thereby improving the clarity of the image of the optical sensor.

[0037] After bonding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com