An automatic packaging device for capacitors

A technology for packaging devices and capacitors, which is applied in the direction of packaging capacitor devices, fixed capacitor shells/packages, capacitors, etc., which can solve the problems of increased packaging difficulty, poor moisture resistance and gas barrier properties, and increased residual products, so as to save human resources. , avoid manual participation, and improve the effect of yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

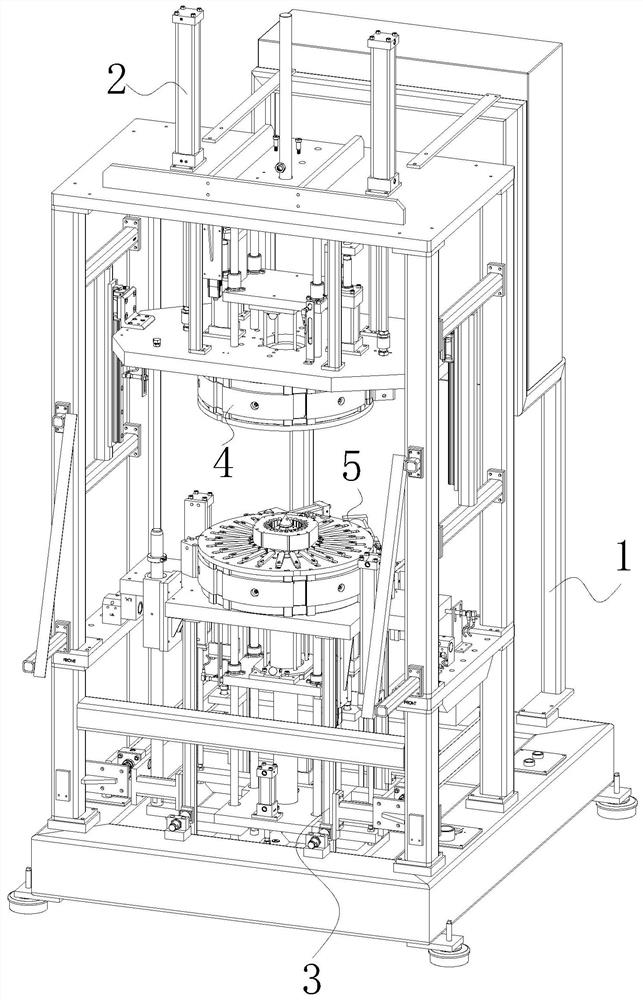

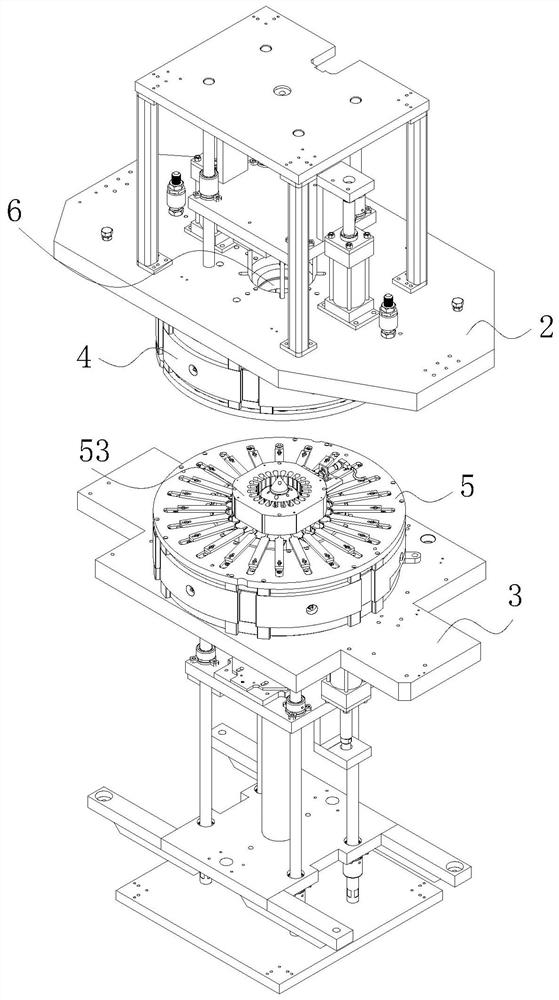

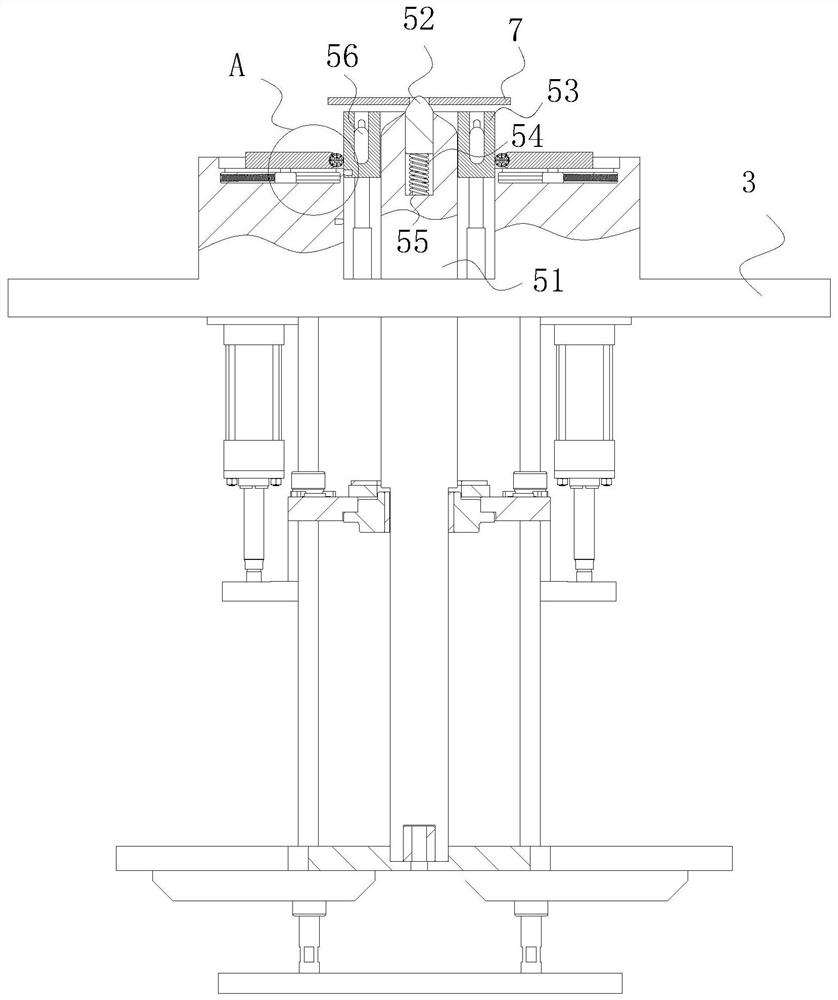

[0021] use Figure 1-Figure 5 An automatic packaging device for capacitors according to an embodiment of the present invention will be described as follows.

[0022] like Figure 1-Figure 5 As shown, a capacitor automatic packaging device according to the present invention includes a main body 1, an upper mounting frame 2, a lower mounting frame 3, an upper fixing block 4 and a lower fixing block 5; the upper end of the main body 1 is slidably connected with an upper mounting frame 2, the lower end of the main body 1 is slidingly connected with a lower mounting frame 3; the interior of the upper mounting frame 2 is fixedly installed with an upper fixing block 4; the inside of the upper fixing block 4 is provided with an insertion hole 6; the lower mounting The inside of the frame 3 is fixedly installed with a lower fixing block 5, and the lower mounting frame 3 is located directly below the upper mounting frame 2; A mounting rod 51 is slidably installed; the upper end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com