Bag body and manufacturing process thereof and knapsack with bag body

A manufacturing process and bag body technology, which is applied in the field of backpacks, can solve problems such as uneven overlapping and folding parts, uneven joints, and burrs on the edges, achieving high flatness, high aesthetics, and avoiding burrs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

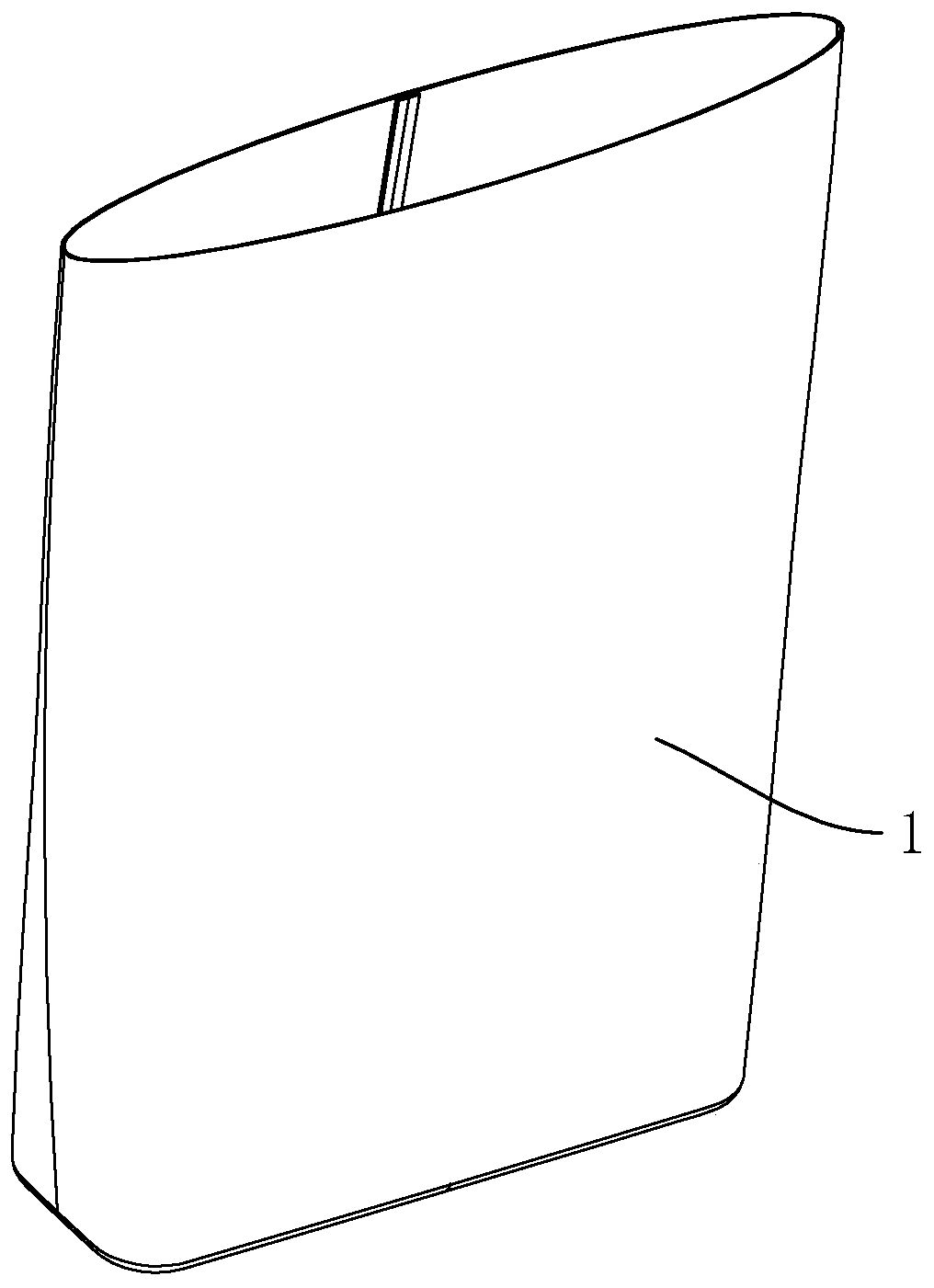

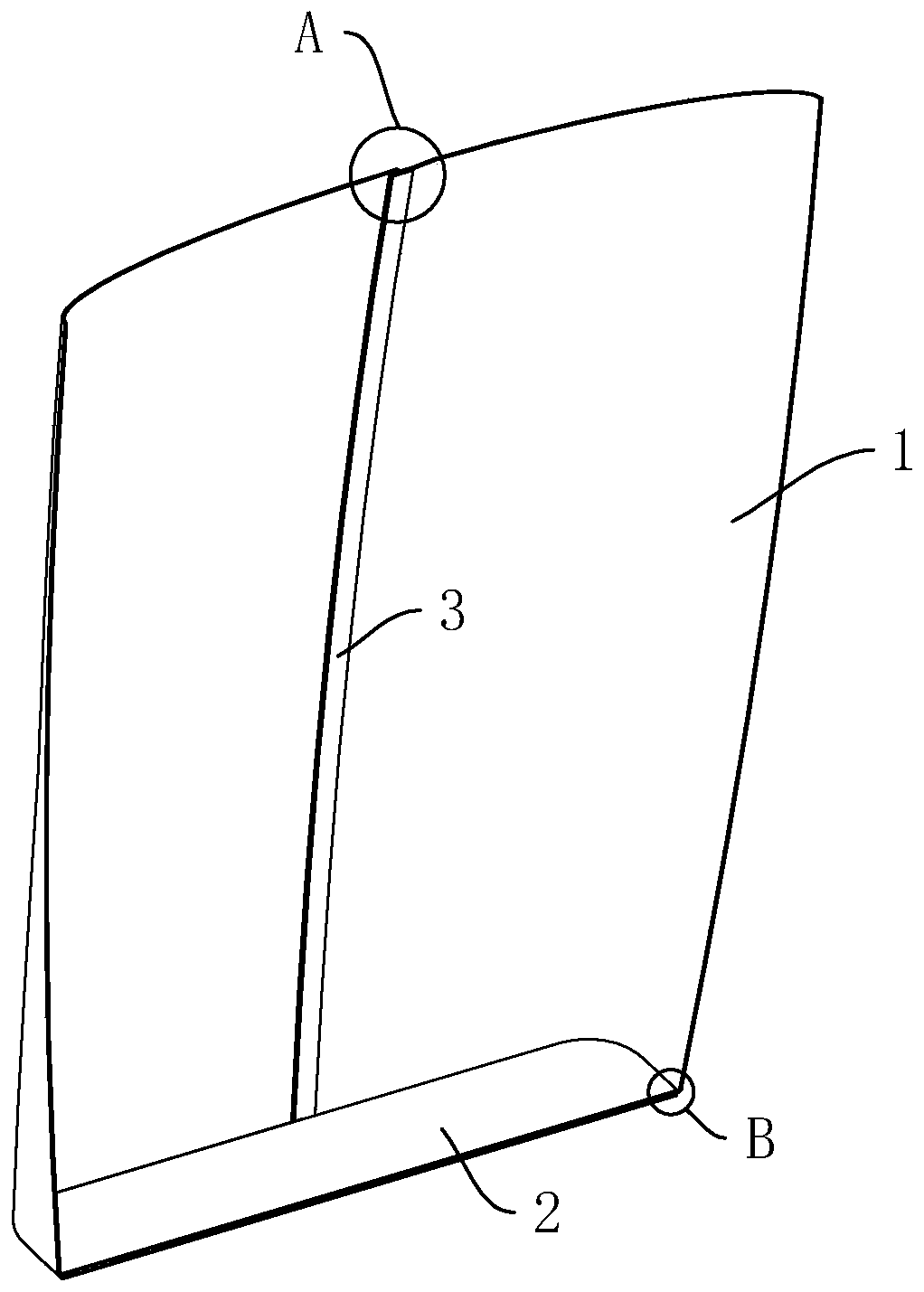

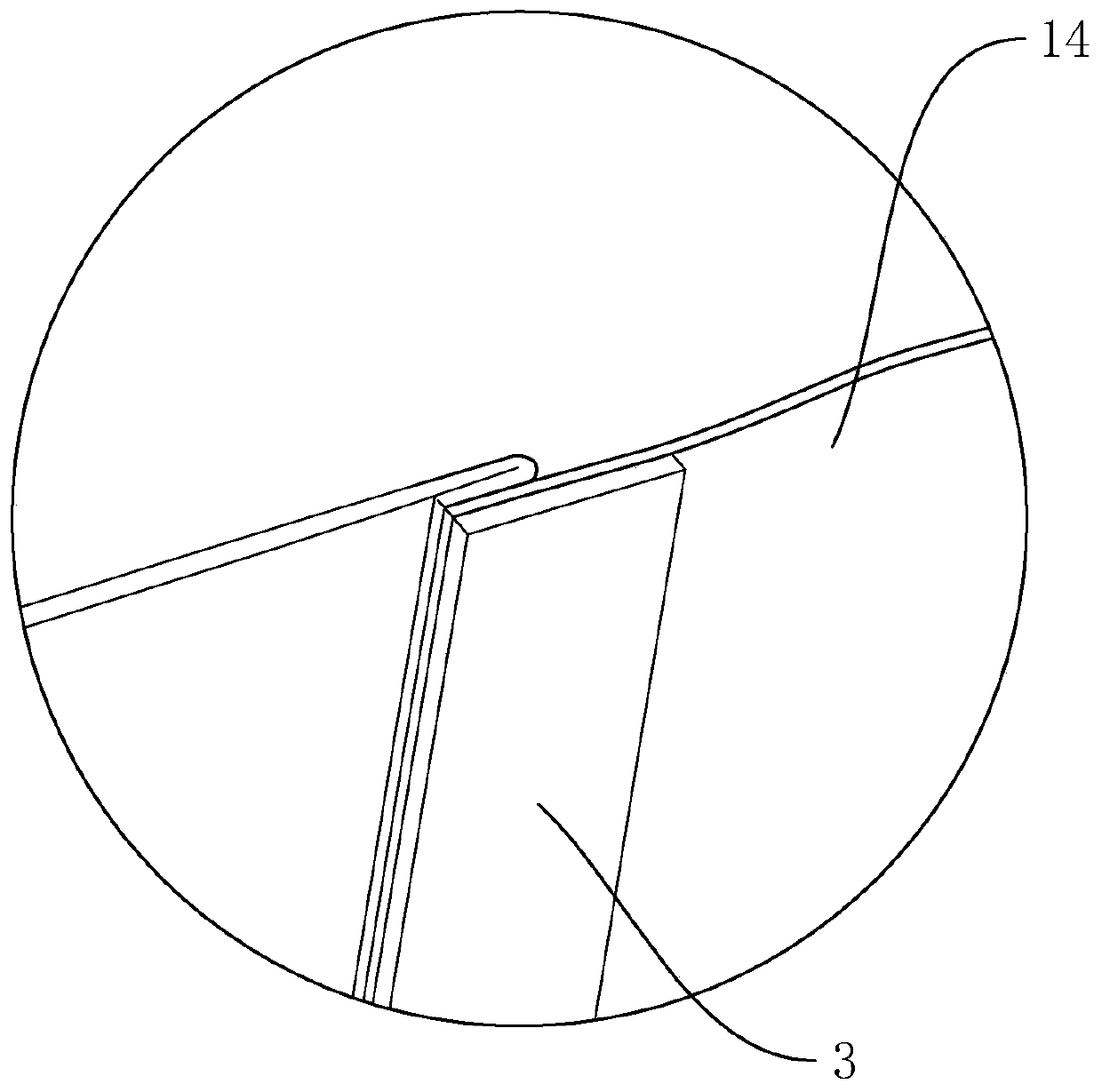

[0043] refer to Figure 1-Figure 4, is a bag body disclosed by the present invention, comprising a cylindrical bag body 1 with upper and lower ends open and a bag bottom 2 connected to the lower end of the bag body 1. The bag body 1 is formed by aligning and sewing two opposite sides of a rectangular sheet. The bag body 1 of the cylindrical body, the fabric of the rectangular sheet is a waterproof composite fabric with one side being a waterproof layer and the other side being a fabric layer, that is, the inner side of the bag body 1 is a waterproof layer, and the outer side of the bag body 1 is a cloth layer, which is waterproof The material of the layer is PVC or EVA or TPU or PU film. In this embodiment, the waterproof layer adopts PVC film, so that the body of the bag is waterproof, and the fabric of the waterproof layer of the PVC film is relatively soft, and the shape of the bag body is convenient. The body of the bag is 1 A waterproof strip 3 is welded on the inner side...

Embodiment 2

[0047] The difference between this embodiment and the first embodiment above is that the edge of the ring-shaped connecting portion 13 facing the inside of the bag body 1 is integrally connected with the edge of the flange 11 .

Embodiment 3

[0049] The difference between this embodiment and the above-mentioned first embodiment is that the bag body 1 includes a back rectangular sheet and a front rectangular sheet with the same width, and the two opposite sides of the back rectangular sheet are respectively connected to the front rectangular sheet. The two opposite sides are sewed one by one to form a cylindrical bag body 1, so that the inner side of the bag body 1 is a waterproof layer, and the outer side of the bag body 1 is a fabric layer. This kind of fabric is relatively soft and can be easily Connect the shoulder straps and other structures of the bag body on the back rectangular sheet, and then sew the two rectangular sheets together, which is convenient for processing, and the shape of the bag body is convenient. A waterproof strip 3 is welded on the inner side of the seam of the bag body 1, The material of waterproof strip 3 is PVC or EVA or TPU or PU strip, and the material of waterproof strip 3 in this emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com