Knee joint spacer and preparation method thereof

A knee joint and spacer technology, applied in knee joints, elbow joints, joint implants, etc., can solve problems such as different experiences, large resistance to movement, scarring, etc., and achieve the effect of easy revision surgery and less pain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

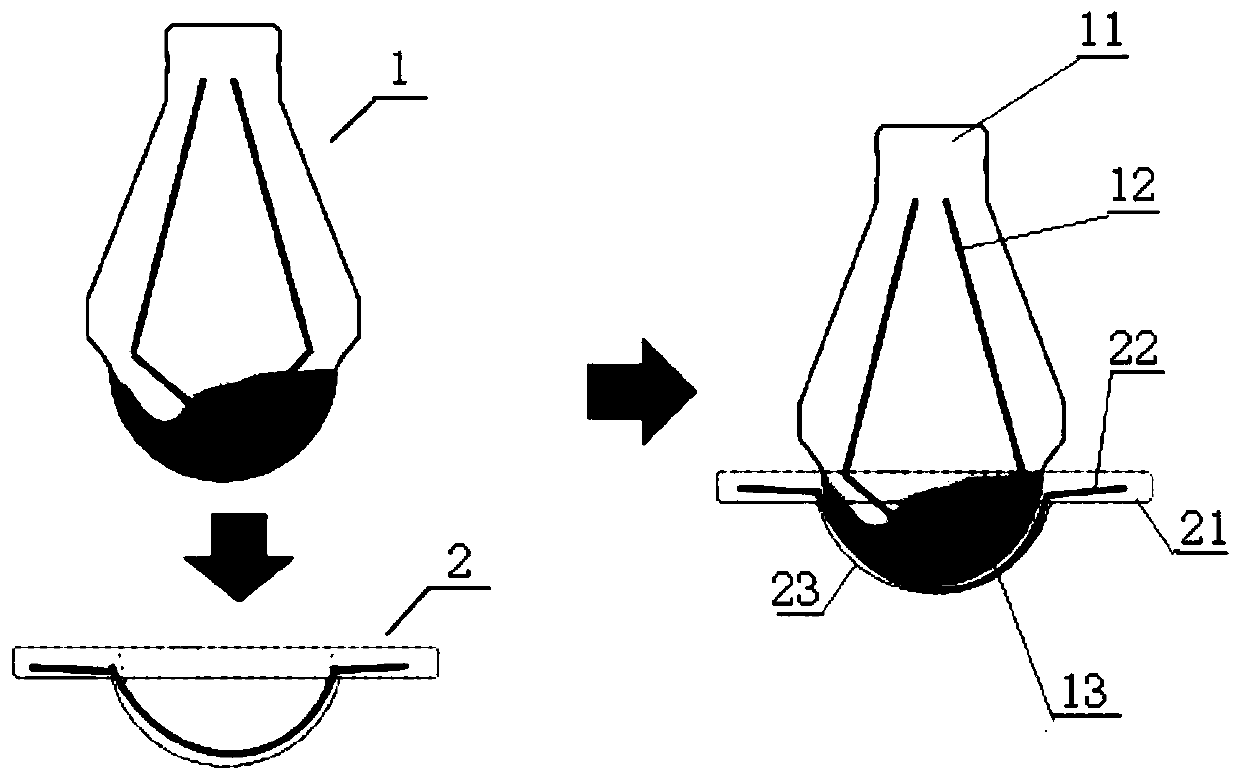

[0058] see Figure 1-12 , the present embodiment provides a knee spacer, including the Spacer femoral side 1;

[0059] The Spacer femoral side 1 includes a first bone cement body part 11, a first Kirschner wire 12 and a first metal prosthesis contact part 13;

[0060] The first bone cement main body 11 includes a first cylinder 111, the lower end of the first cylinder 111 is connected with a first circular platform 112 with a narrow top and a wide bottom, and a second cylindrical body 113 is connected with the lower end of the first circular platform 112 , the lower end of the second cylinder 113 is connected with a second circular platform 114 with a wide top and a narrow bottom;

[0061] The first metal prosthesis contact part 13 is a semi-spherical structure with the spherical surface facing downwards, and the upper surface of the semi-spherical structure is connected to the lower end of the second round platform 114;

[0062] The first Kirschner wire 12 is located in the m...

Embodiment 2

[0072] This embodiment provides a method for preparing a knee joint spacer, comprising the following steps:

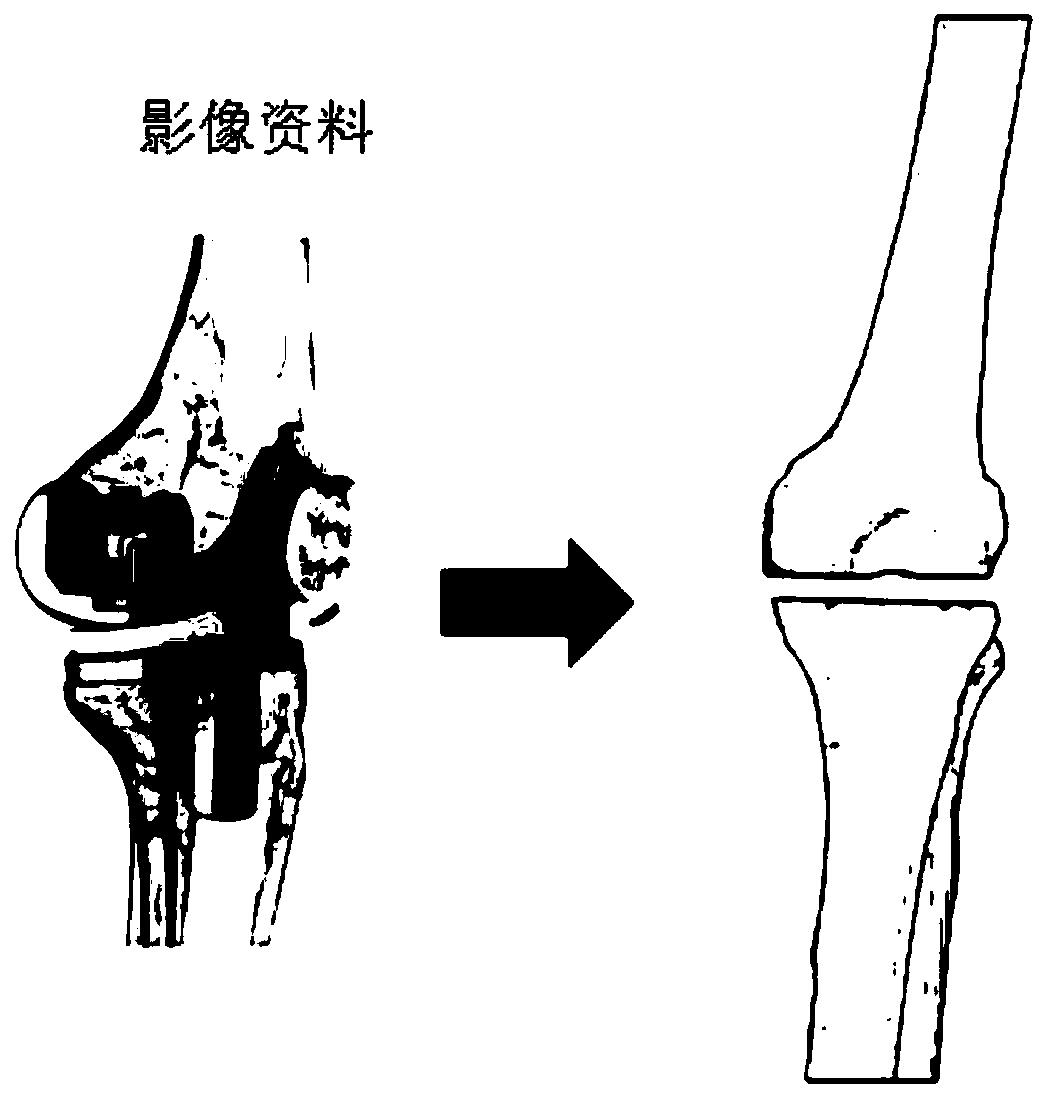

[0073] Step 1, obtain the image data of the patient's knee joint through the patient's X-ray or CT;

[0074] Step 2, converting the image data into editable three-dimensional data of the knee joint through a computer;

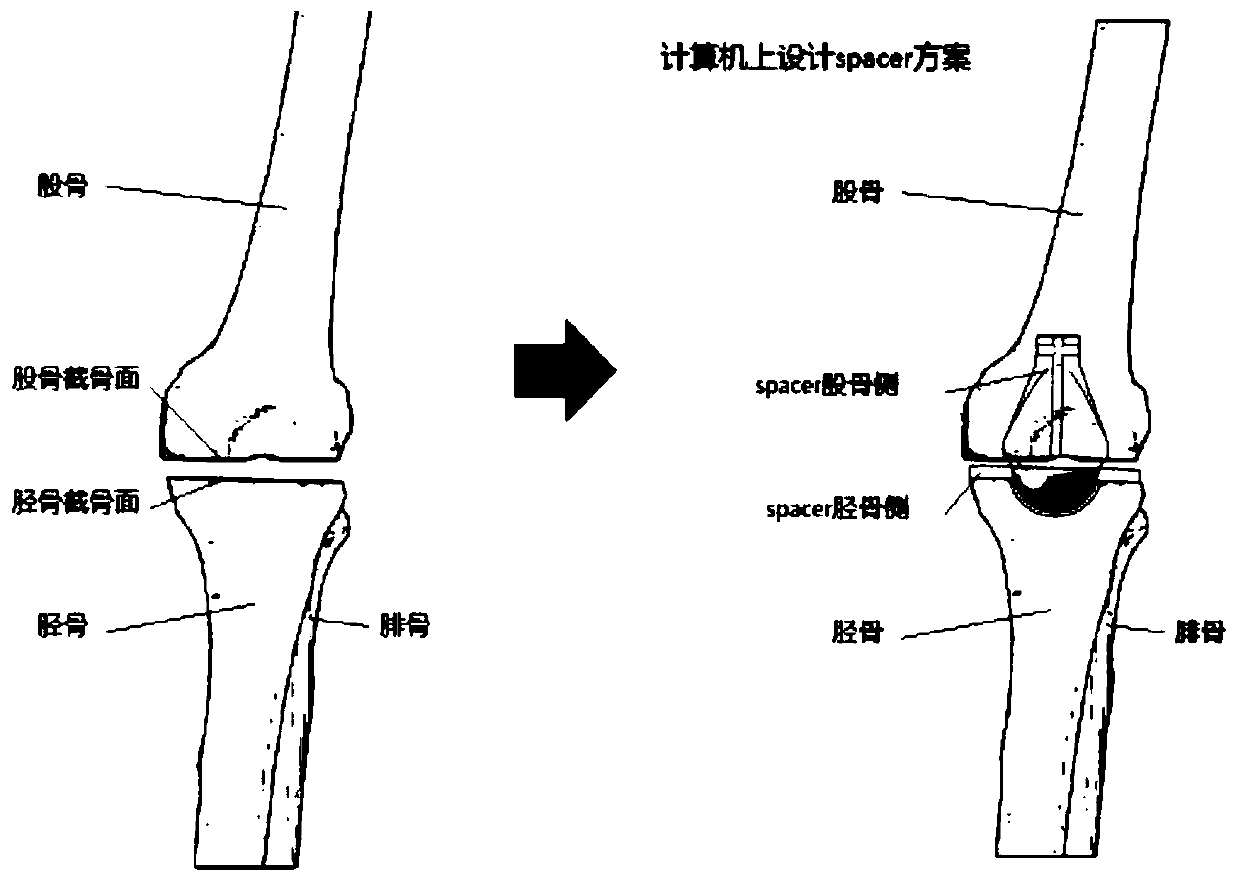

[0075] Step 3, determine the osteotomy scheme on the computer according to the three-dimensional data of the knee joint;

[0076] Step 4, formulate Spacer femoral side 1 and Spacer tibial side 2 plans on the computer;

[0077] Step 5, according to the Spacer femoral side 2 and Spacer tibial side 2 plans, design and determine the femoral side medullary canal reamer and tibial side medullary canal reamer;

[0078] Step 6: Design the specific structures of Spacer femoral side 1 and Spacer tibial side 2 according to the femoral and tibial canal rasp scheme;

[0079] Step 7, according to the specific structure of the designed Spacer femoral side 1 and Spa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com