Die for die cutting of tag paper

A label paper and die-cutting technology, which is applied in metal processing and other directions, can solve the problems of narrow application range and achieve the effect of increasing application range, increasing stability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings.

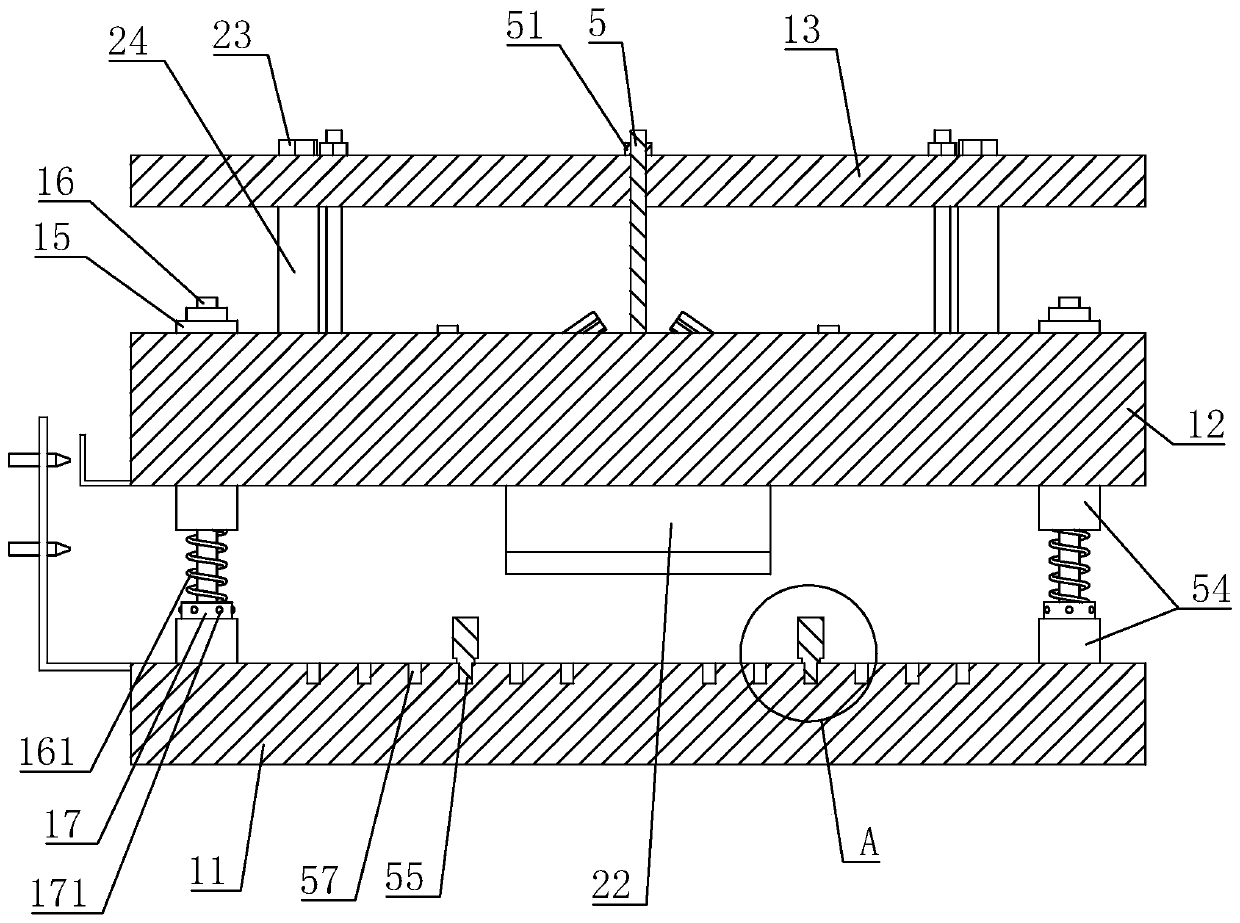

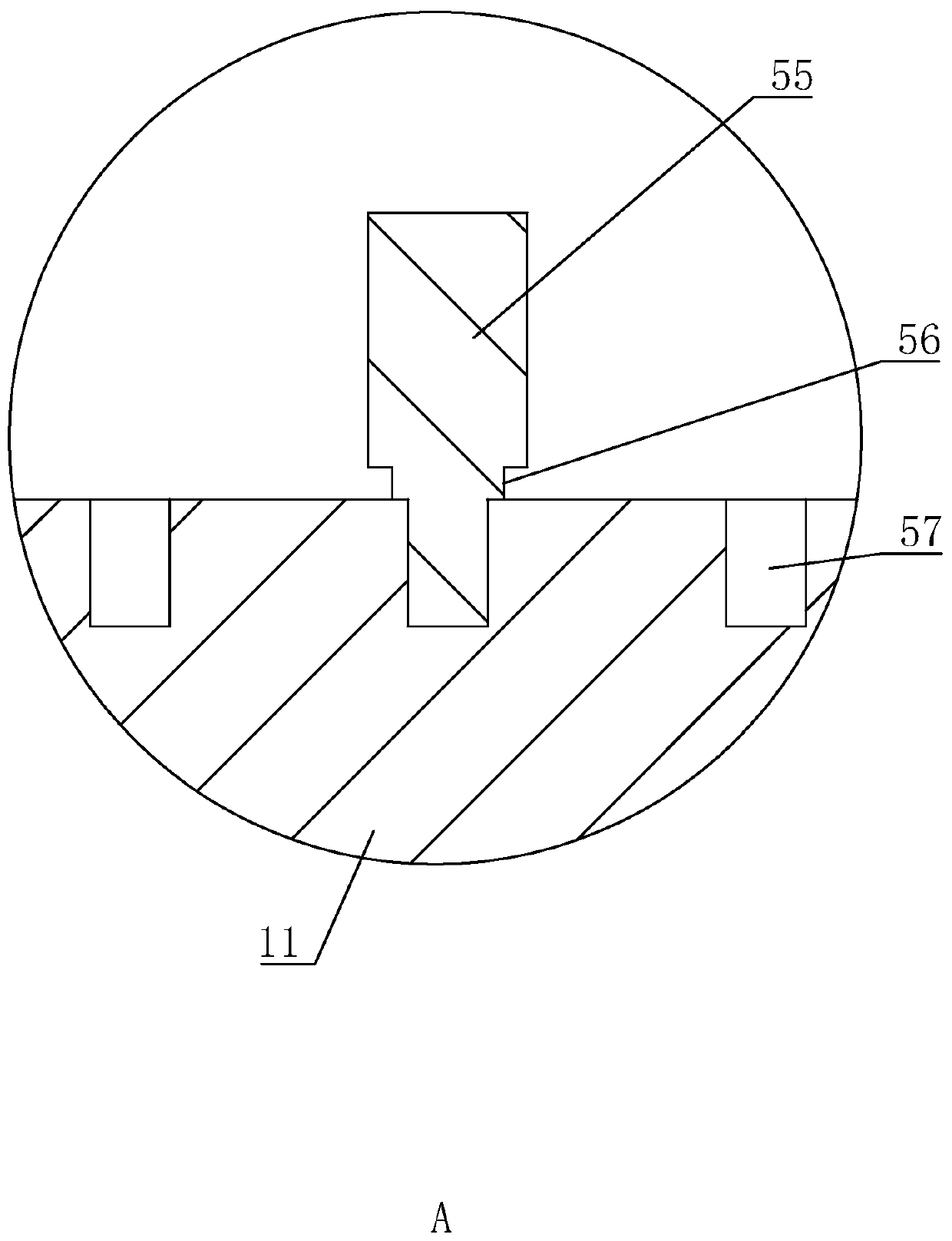

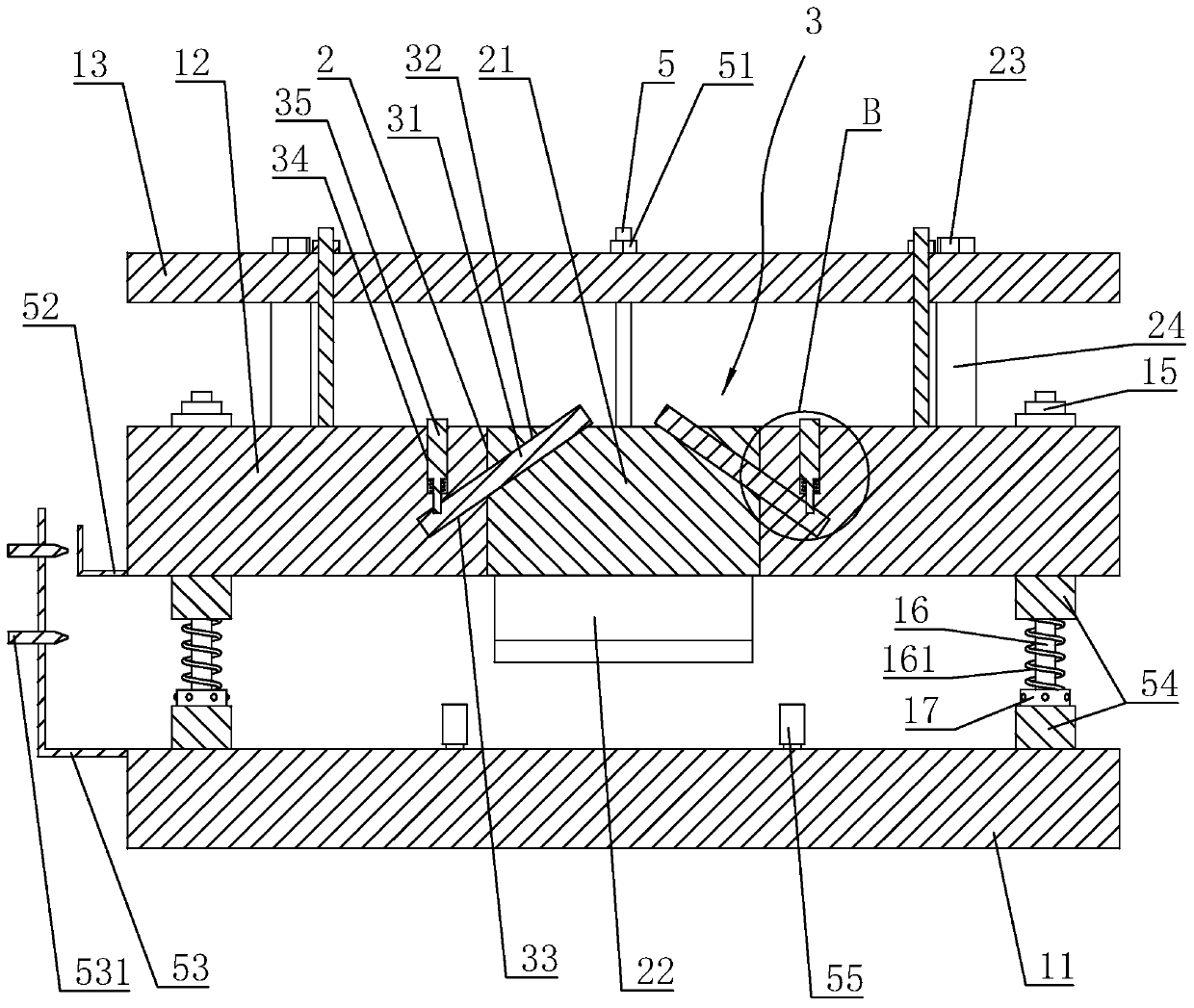

[0039] like figure 1 and figure 2 As shown, it is a mold for label paper die-cutting disclosed by the present invention, which includes a lower template 11, an upper template 12 and a backing plate 13 distributed sequentially from bottom to top. The label is placed on the lower template 11, and the lower template 11 is threaded. Two sets of limit columns 55 symmetrically distributed about the label, each set of limit columns 55 are two in number and arranged along the label transmission direction, each limit column 55 is provided with a limit groove 56 on the side wall, and the upper template 11 There are also screw holes 57 screwed and matched with the limit posts 55. Each limit post 55 corresponds to a number of screw holes 57 and the screw holes 57 are arranged perpendicular to the label transmission direction. The operator selects the corresponding posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com