Sectional insulator and contact rail system

A segmented insulator and segmented insulation technology, which is applied in the direction of power rails, overhead lines, etc., can solve the problems of segmental insulators, such as channeling, and achieve the effects of avoiding channeling, improving work safety, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

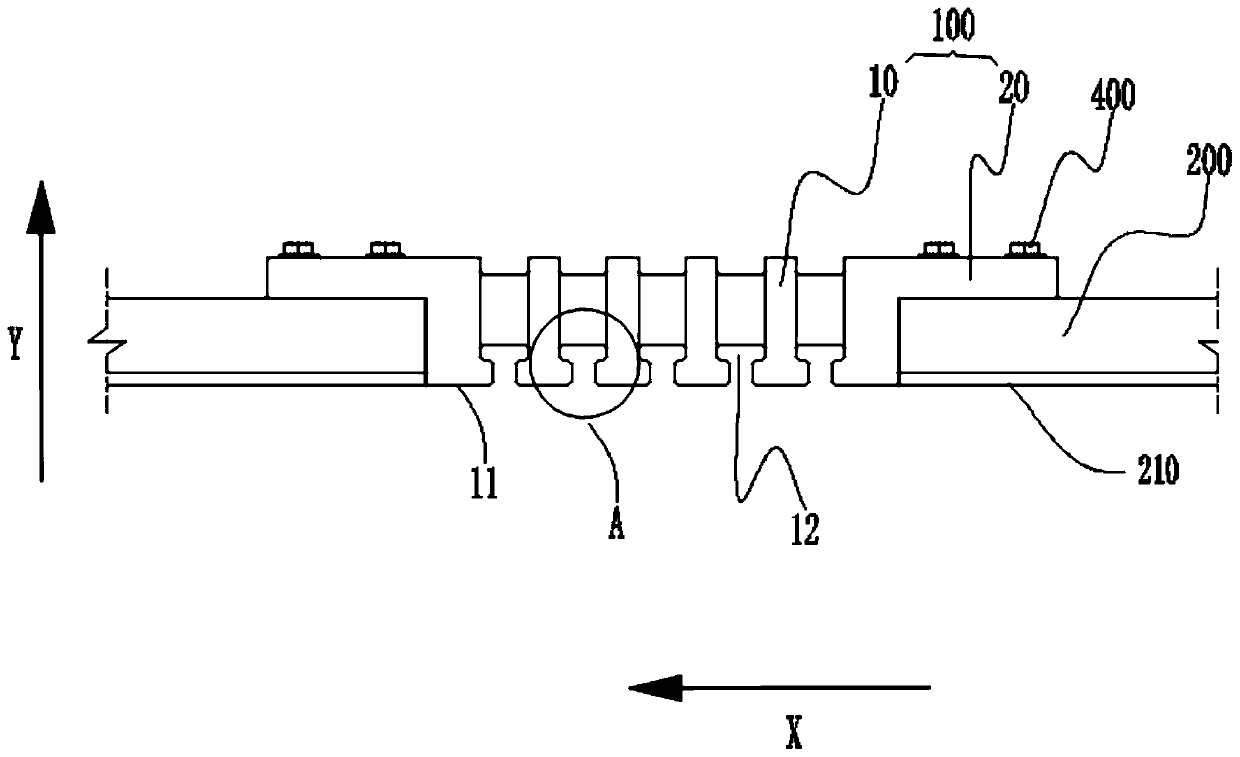

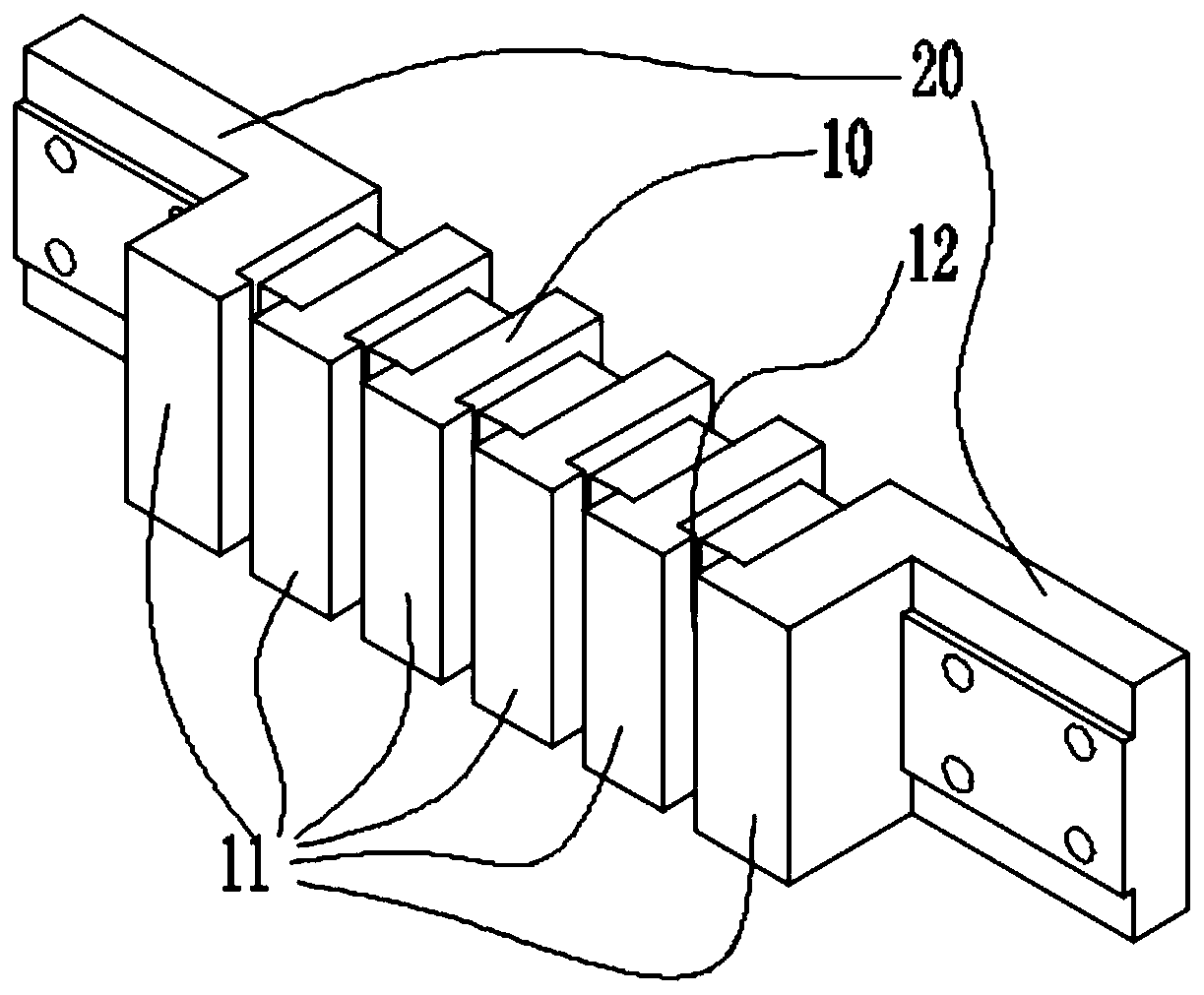

[0038] Please also refer to figure 1 and figure 2 , the segmented insulator 100 provided by the embodiment of the present application will now be described. The segment insulator 100 is used in a busbar system to realize an insulated connection between busbar segments 200 .

[0039] see figure 1 , the segmented insulator 100 has a first working surface 11, correspondingly, the contact rail segment 200 at both ends has a second working surface 210, the first working surface 11 and the second working surface 210 are flush with each other, the first working surface Both the surface 11 and the second working surface 210 are used for sliding the power receiving shoe 300 . Specifically, the first working surface 11 and the second working surface 210 are both figure 1 When working, the power receiving shoe 300 alternately slides on the first working surface 11 and the second working surface 210 to realize power supply to each contact rail segment 200 .

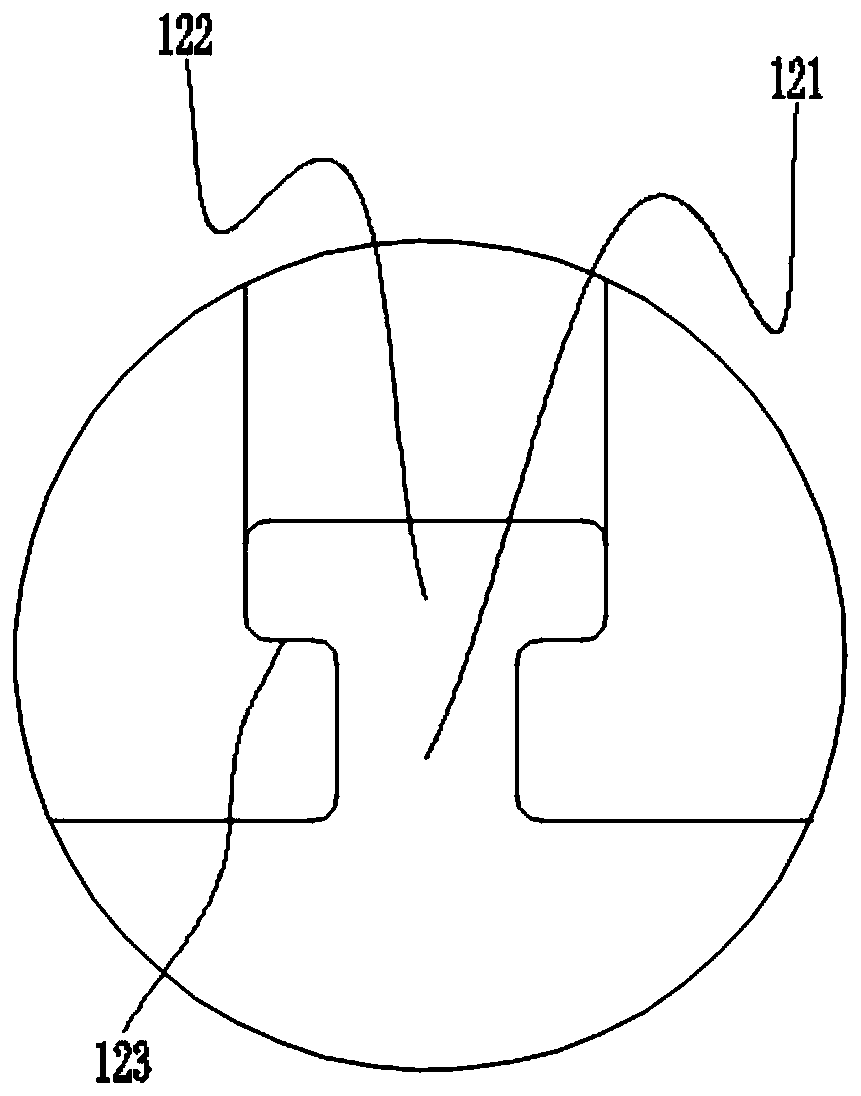

[0040] A plurality of f...

Embodiment 2

[0055] The technical features of the segmented insulator 100 in this embodiment are basically the same as those of a segmented insulator 100 in the embodiment, the difference is that in this embodiment, please refer to Figure 7 , along the depth direction of the first groove 12, the width of the second groove segment 122 along the sliding direction of the power receiving shoe 300 first gradually increases, and then gradually decreases. Moreover, the first cross section of the second groove segment 122 is connected by an arc segment, specifically an ellipse.

Embodiment 3

[0057] The technical features of the segmented insulator 100 in this embodiment are basically the same as those of a segmented insulator 100 in the embodiment, the difference is that in this embodiment, please refer to Figure 8 , along the depth direction of the first groove 12 , the width of the second groove segment 122 gradually increases along the sliding direction of the power receiving shoe 300 . In addition, the first section of the second slot section 122 is connected by an arc section and a straight section, which is T-shaped specifically, and the top end is provided with rounded corners of the arc section.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com