Sock packaging machine

A technology for packaging machines and socks, applied in the field of industrial manufacturing, can solve problems such as low packaging efficiency and difficult product quality control, and achieve the effects of high applicability, simple and easy-to-understand adjustment devices, and labor saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

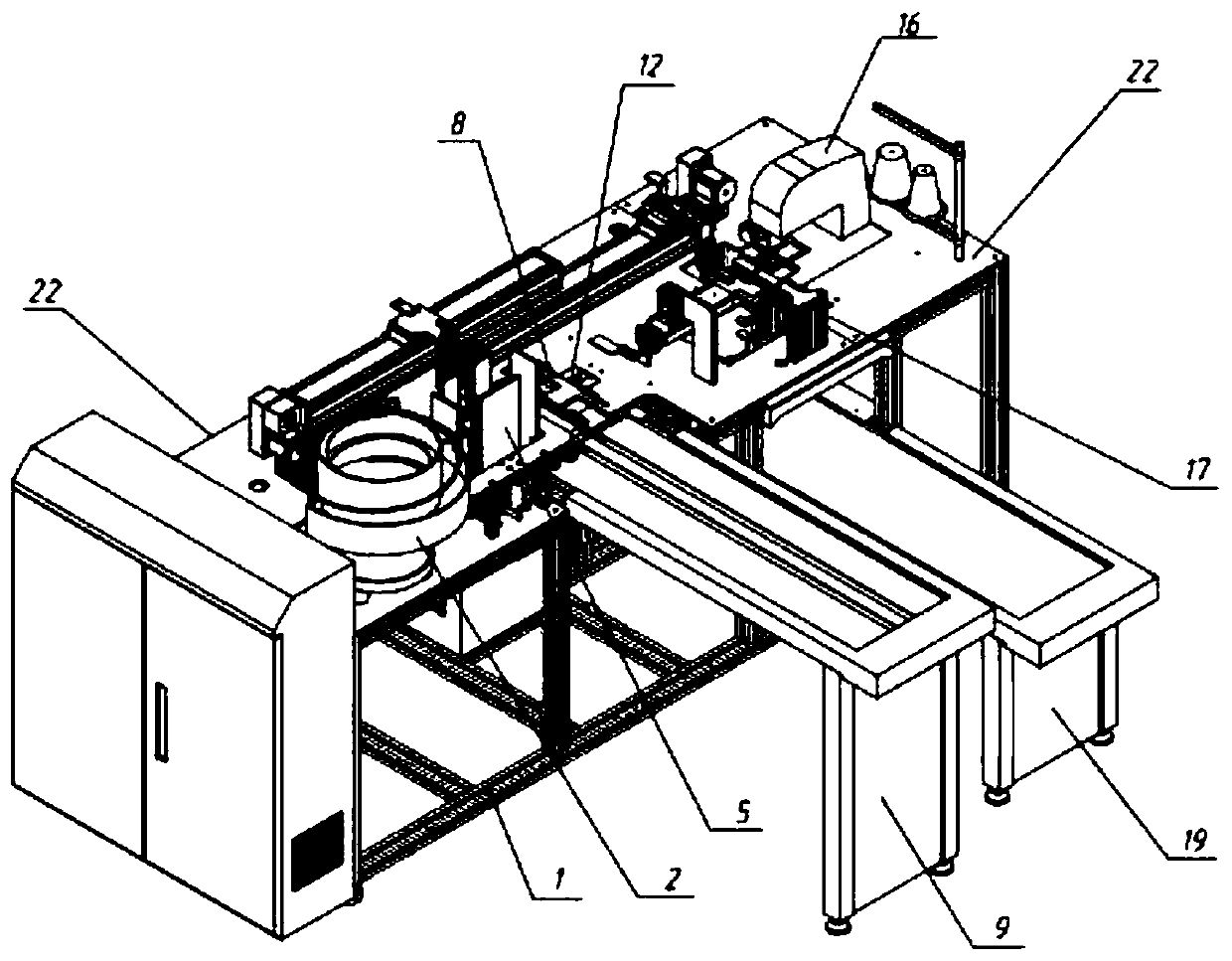

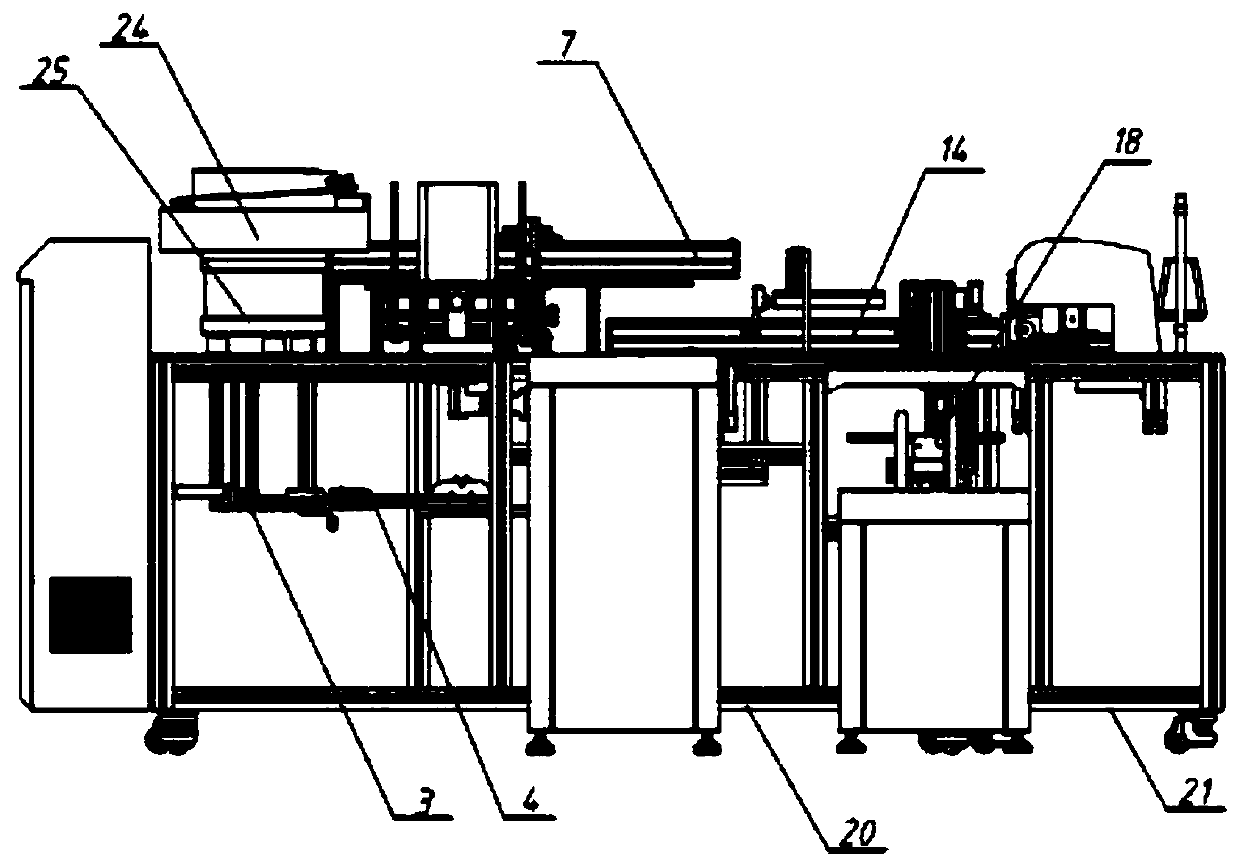

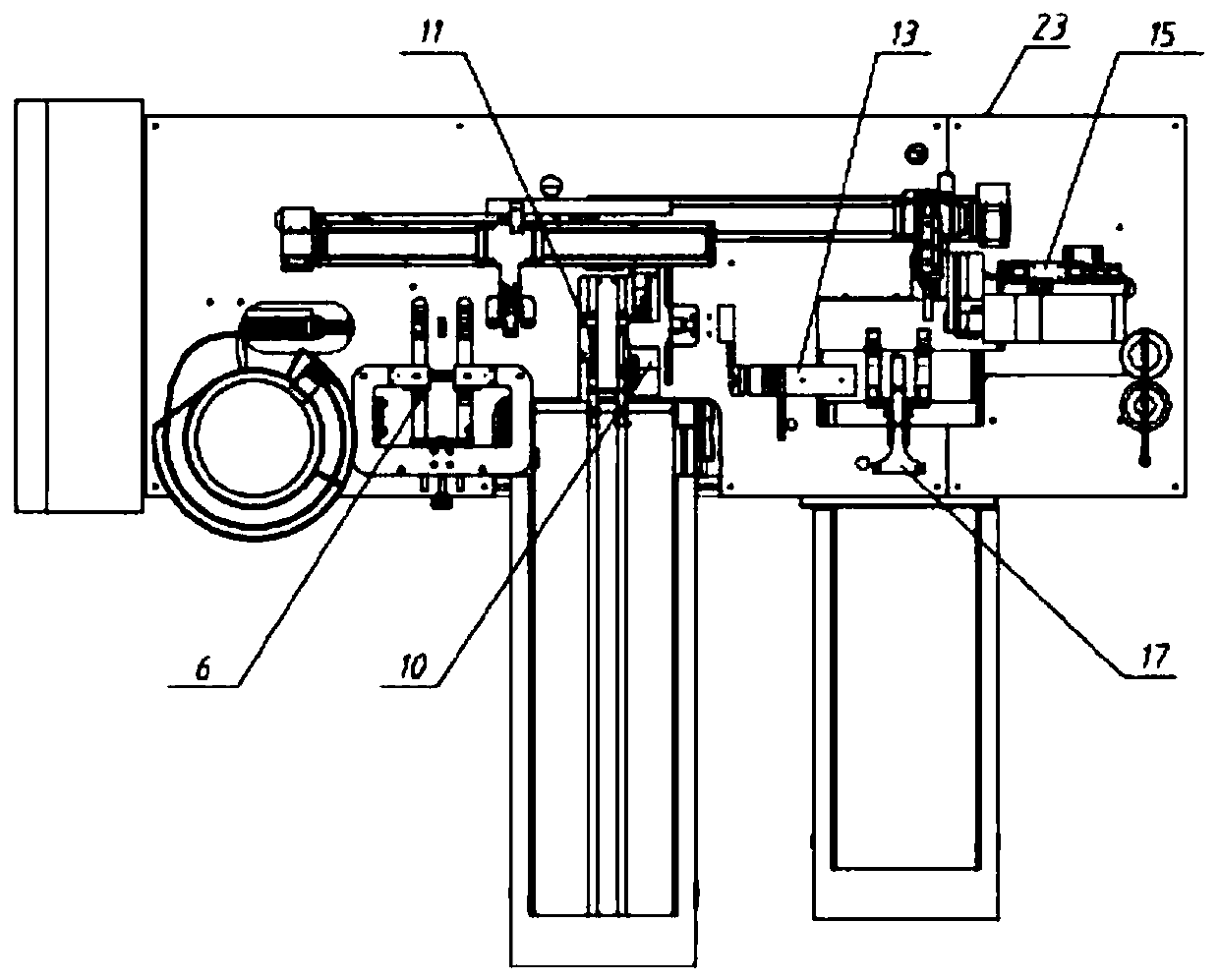

[0051] A kind of sock packing machine of the present invention, as Figure 1 to Figure 3 As shown, it includes a frame 1, and the frame 1 is sequentially connected with a sock hook mechanism, a paper card mechanism, a sock moving mechanism, a staple mechanism and a sock withdrawing mechanism, and the sock hook mechanism can push out the sock hook and insert the sock hook into the In the sock hook opening of the paper card, the paper card mechanism can access and fold the paper card;

[0052] The sock hook mechanism includes a sock hook vibrating plate 2, a hook pushing device 3 and a rotating clip hook device 4, and the sock hook vibrating plate 2 is fixedly connected to the frame 1, such as Figure 4 As shown, the push hook device 3 is located directly below the sock hook vibrating plate 2 guide rods, the push hook device 3 includes a push ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com