Construction method of steel trestle

A construction method, steel trestle technology, applied in bridges, bridge construction, infrastructure engineering, etc., can solve problems affecting the load-bearing capacity of steel trestles, offset of support points of steel trestles, low actual load-bearing of bridge bodies, etc., to prevent Offset, Shock Reduction, Impact Reduction Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

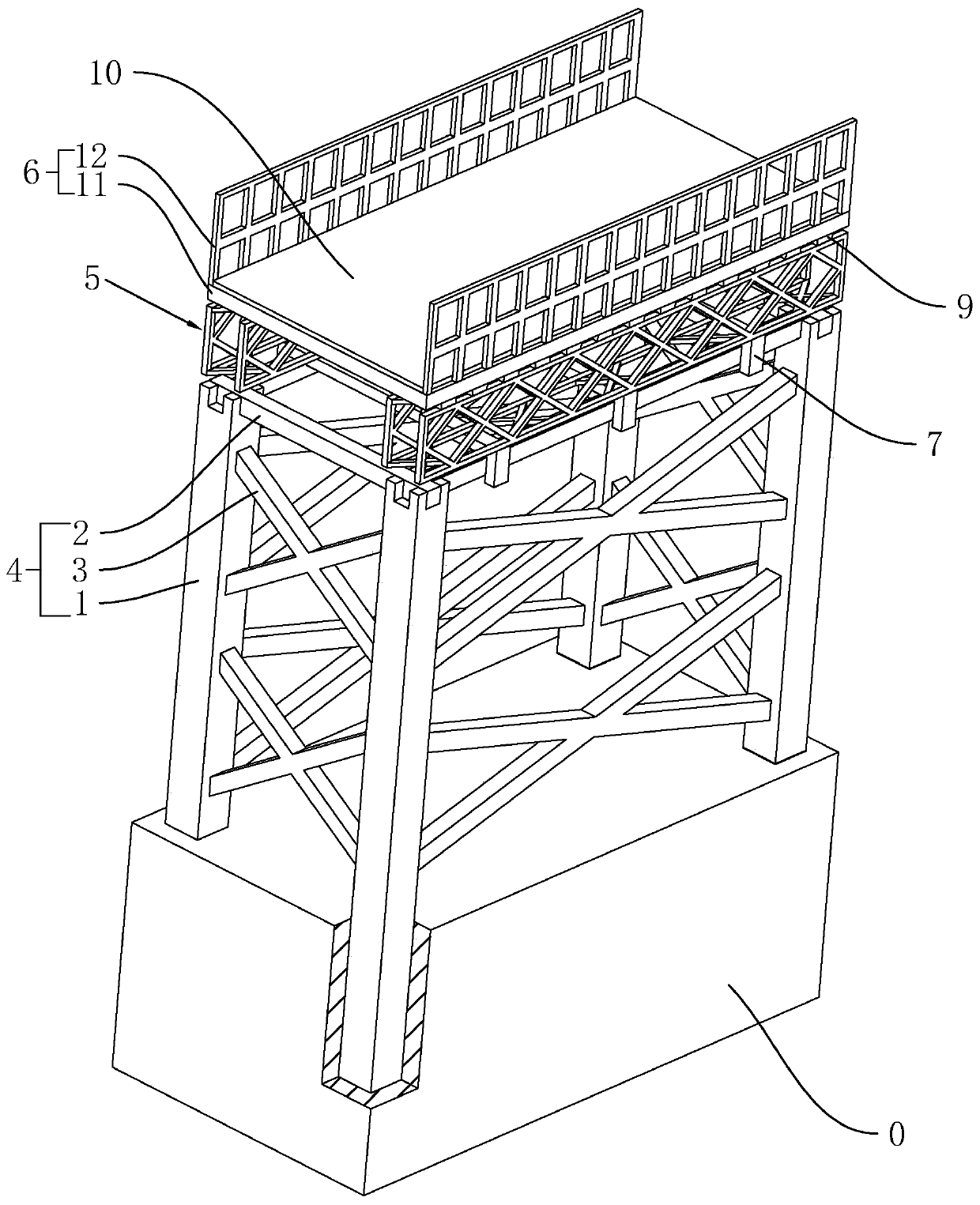

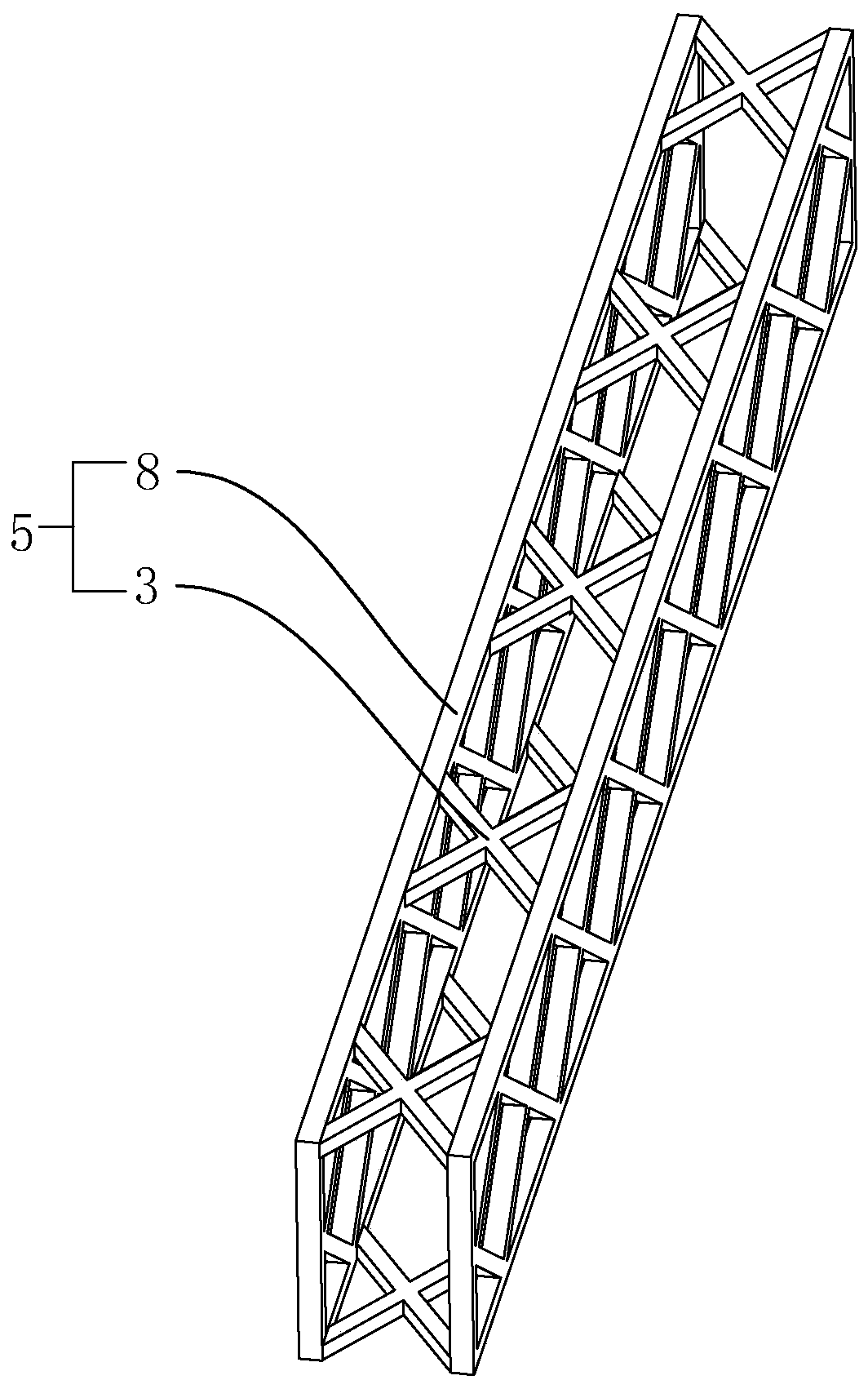

[0047] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0048] refer to figure 1 , is the construction method of a kind of steel trestle bridge disclosed by the present invention, comprises the following steps:

[0049] Step 1: Construction survey, survey the construction area before construction, and formulate the construction plan according to the survey situation of the construction area.

[0050] Step 2: Insert and drive steel pipe piles 1, and insert and drive two rows of steel pipe piles 1 evenly along the direction perpendicular to the flow of the river on the river bed 0. The insertion and driving methods are as follows:

[0051] A1: Positioning by inserting dots, using GPS coordinates to locate dots, and GPS coordinates using GPS wireless positioning equipment for positioning;

[0052] A2: Cofferdam construction, build a cofferdam around the positioning point, and pump the water in the cofferdam away fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com