Circulating construction method of aluminum alloy templates

A technology of aluminum alloy formwork and construction method, which is applied in the connection parts of formwork/formwork/work frame, formwork/formwork member, formwork treatment, etc., can solve the problem of low aluminum alloy turnover rate and poor turnover use effect, etc. problem, to achieve the effect of good turnover, reduce deformation or edge damage, and high transformation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

[0027] Embodiments of the invention are:

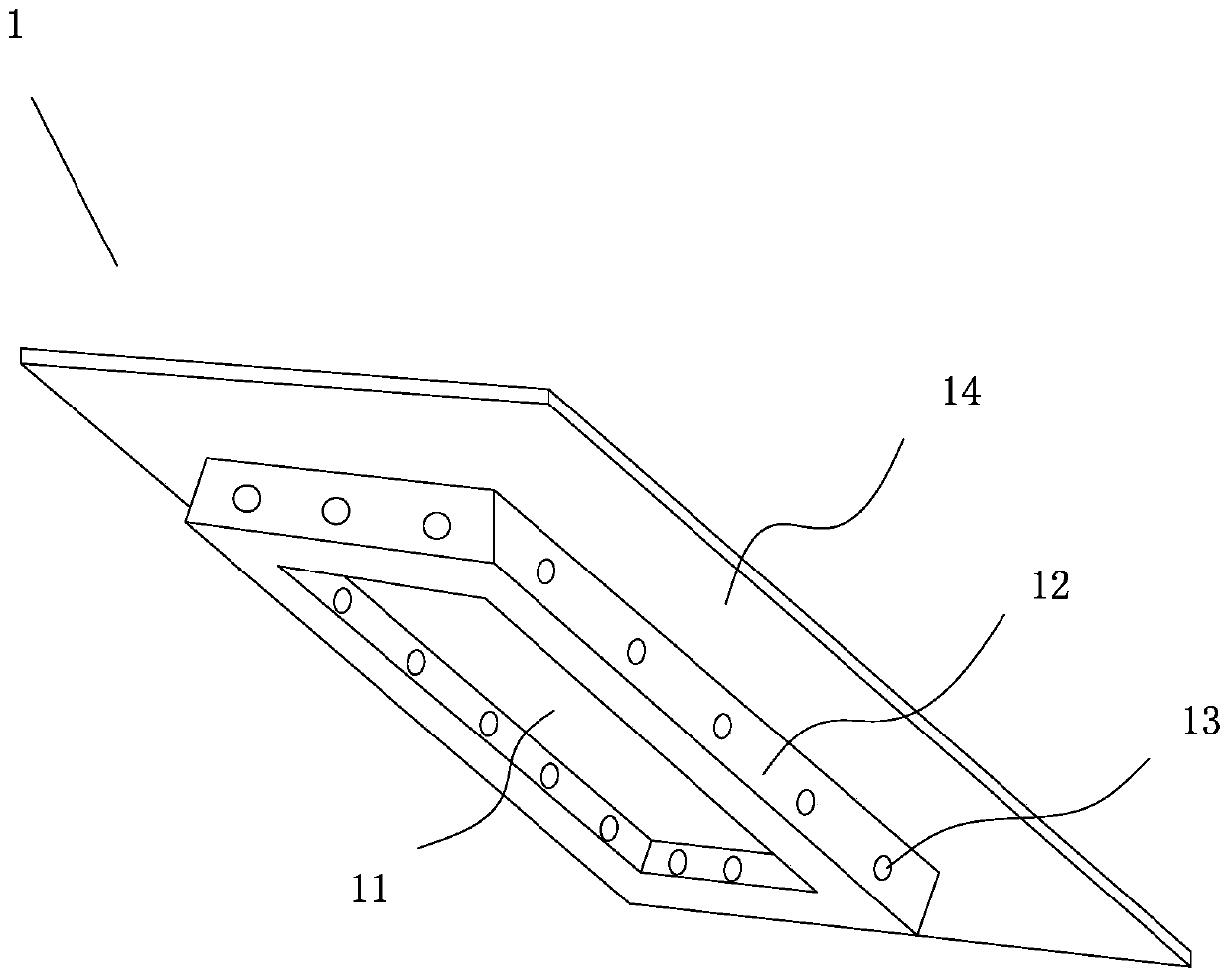

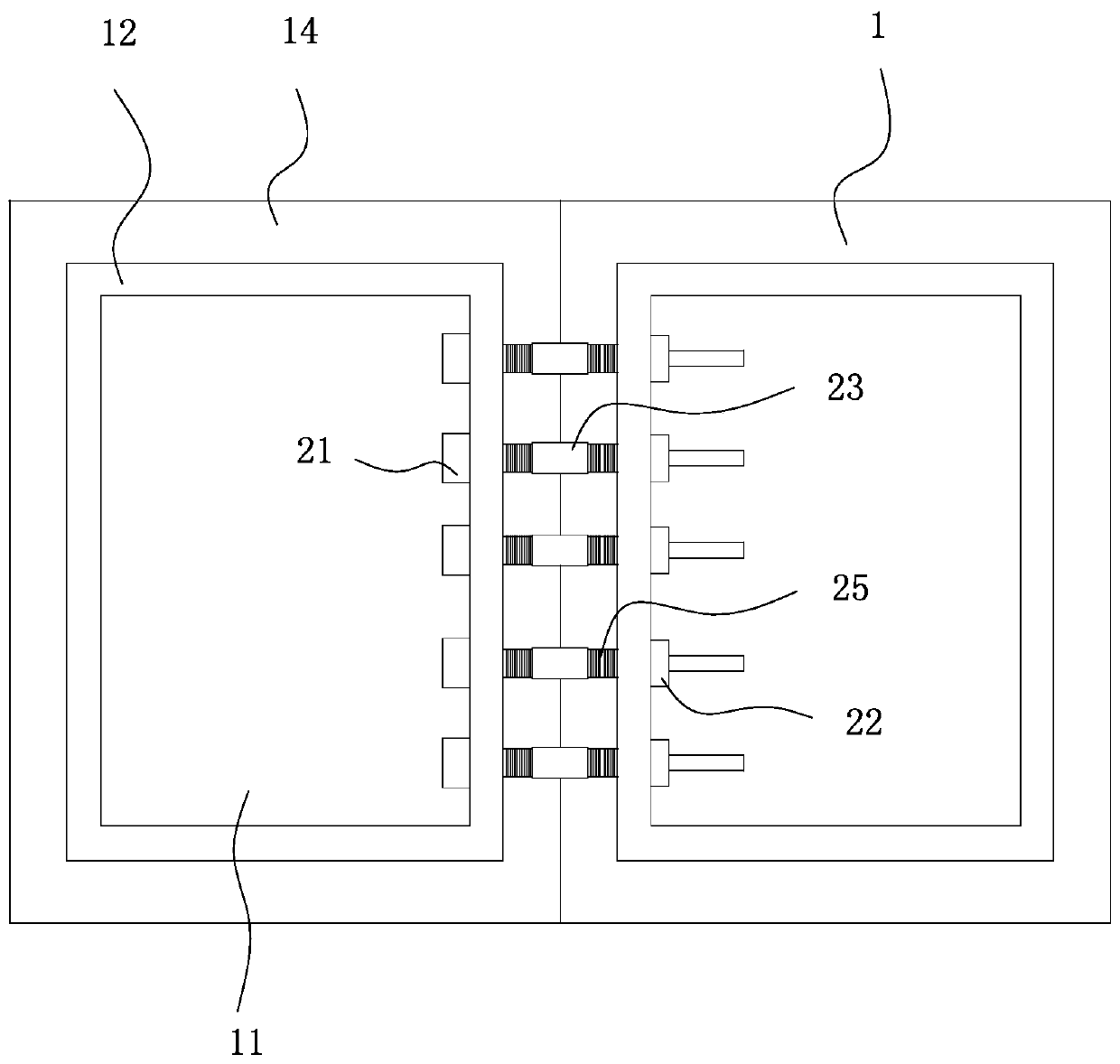

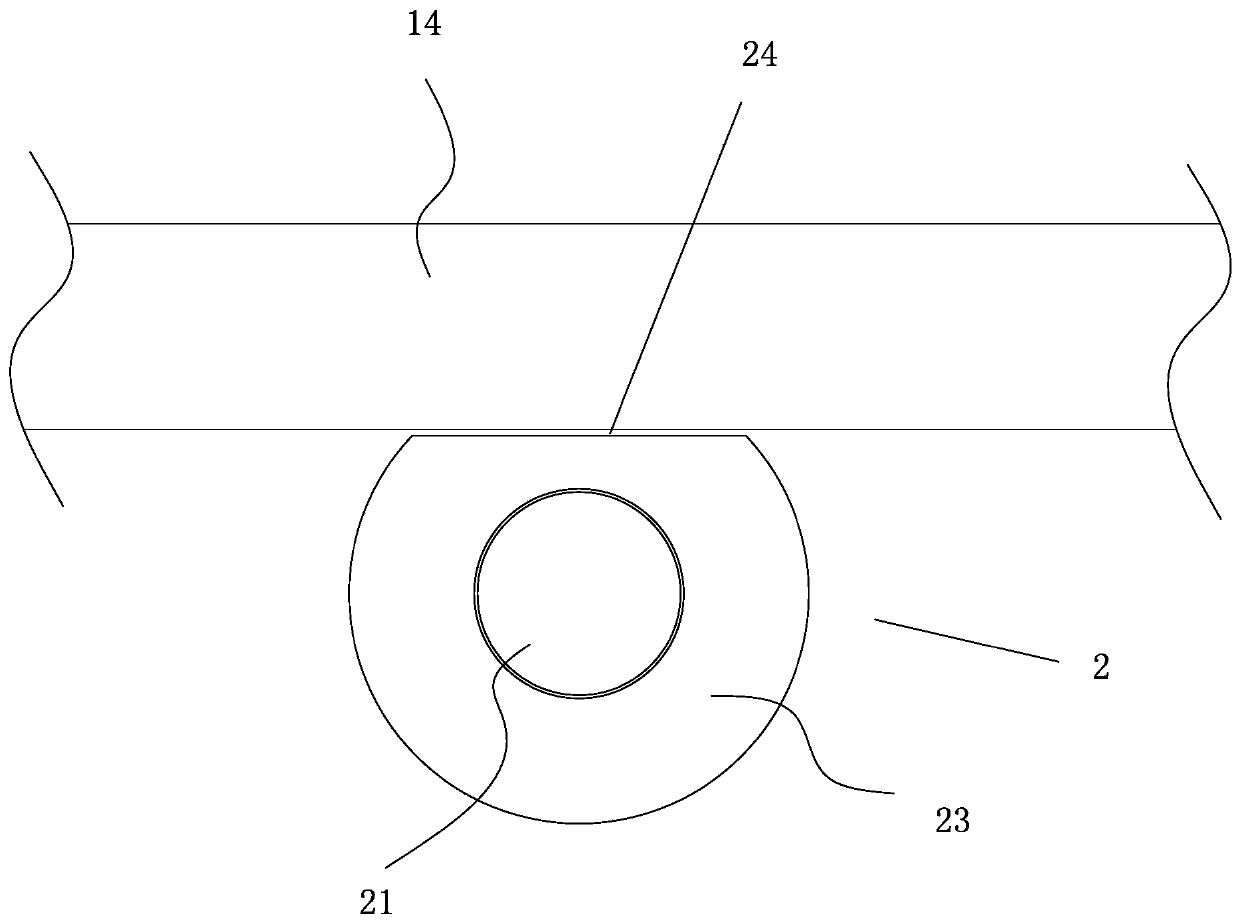

[0028] refer to figure 1 , figure 2 and image 3 As shown, an aluminum alloy formwork turnover construction method includes several aluminum formwork bodies 1 and connectors 2 for installing and connecting two adjacent aluminum formwork bodies 1. The aluminum formwork body 1 includes an aluminum panel 11 and an aluminum panel 11 is a frame 12 surrounded by four frame bars on one side, the frame 12 is parallel to the aluminum panel 11 and perpendicular to the frame bars of the frame 12, and is provided with mounting holes 13, and the periphery of the aluminum panel 11 extends outwards There is an extension part 14, the extension part 14 is integrally connected with the aluminum panel 11, the thickness dimension of the extension part 14 is larger than the thickness dimension of the aluminum panel 11, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com