Lining trolley and tunnel secondary lining construction method using lining trolley

A technology for lining trolleys and trolleys, which is applied in tunnels, shaft linings, tunnel linings, etc., can solve the problems of heavy labor burden on construction personnel, affecting the efficiency of secondary lining construction, and slow adjustment speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

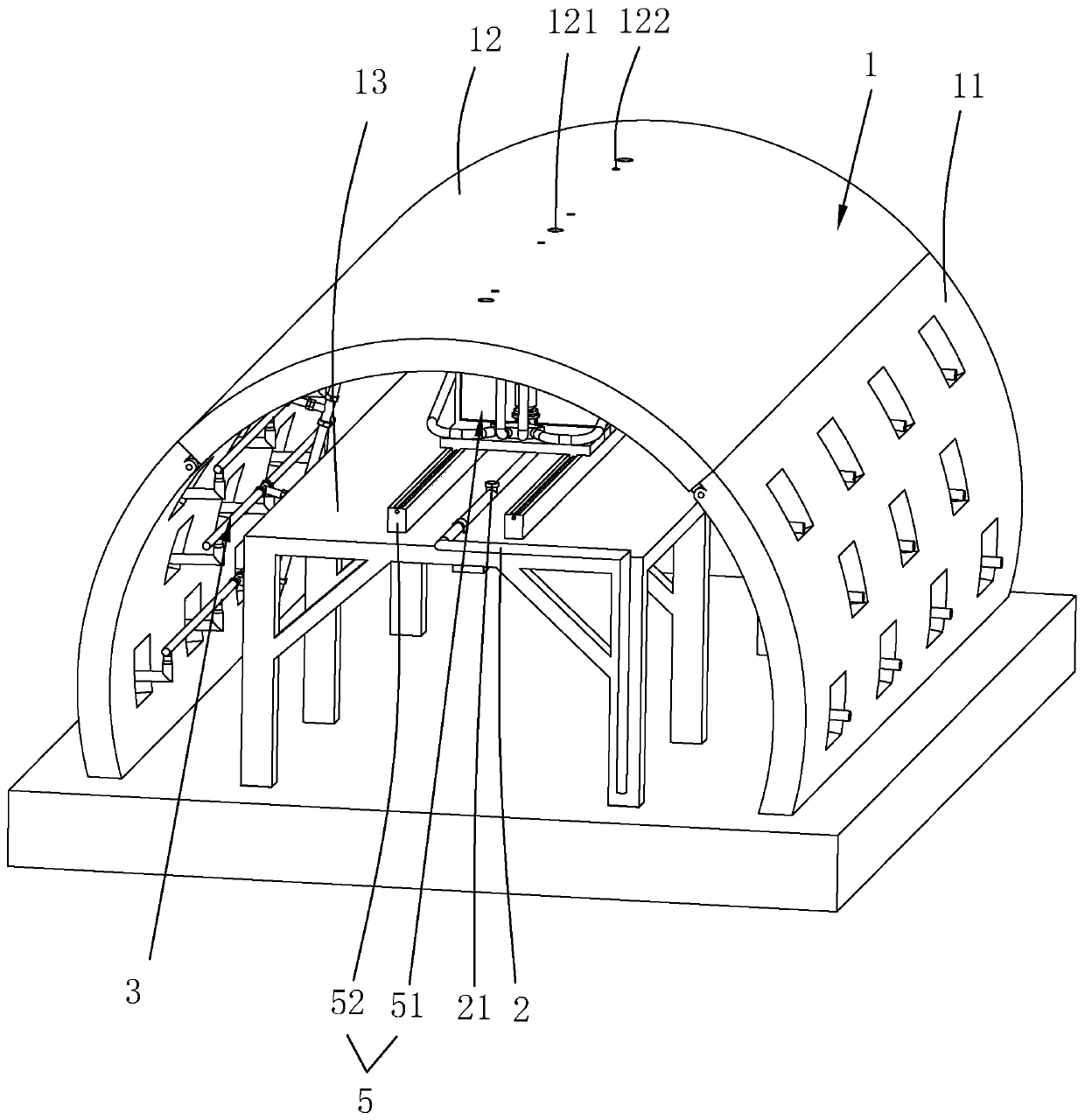

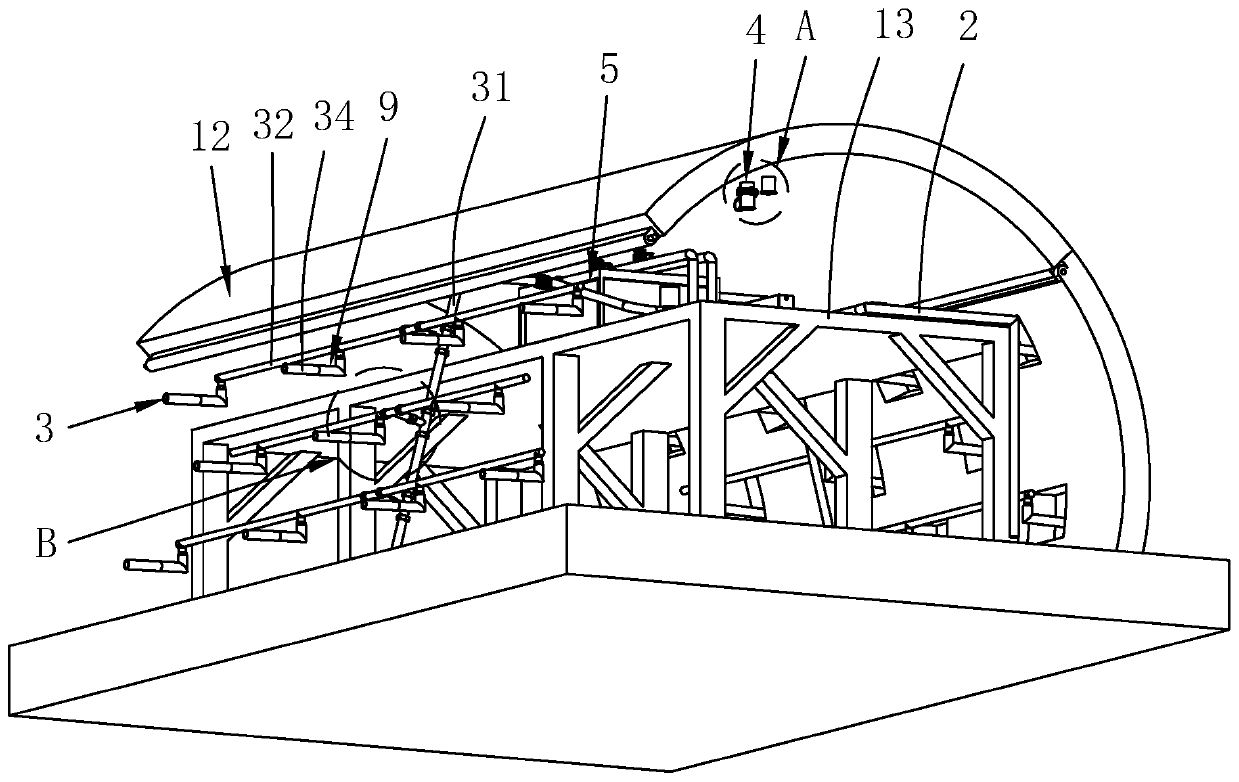

[0051] refer to figure 1 , is a lining trolley disclosed by the present invention, comprising a trolley body 1, a hinged side form 11 and a top form 12 are installed on the outside of the trolley body 1, and top form pouring pipes are arranged at intervals along the centerline direction on the top form 12 121 and belt mold grouting port 122, the trolley body 1 is also equipped with a slurry delivery pipe 2 and a side mold pouring pipeline 3, and a number of slurry outlets 21 are installed on the slurry delivery tube 2, and the slurry outlets 21 correspond to the side molds respectively. The pouring pipeline 3 feed inlet, the top mold pouring pipe 121 and the molded grouting port 122 are arranged. The trolley body 1 is also welded with a bearing platform 13 below the top form 12, and the integrated casting module 5 is arranged on the bearing platform 13.

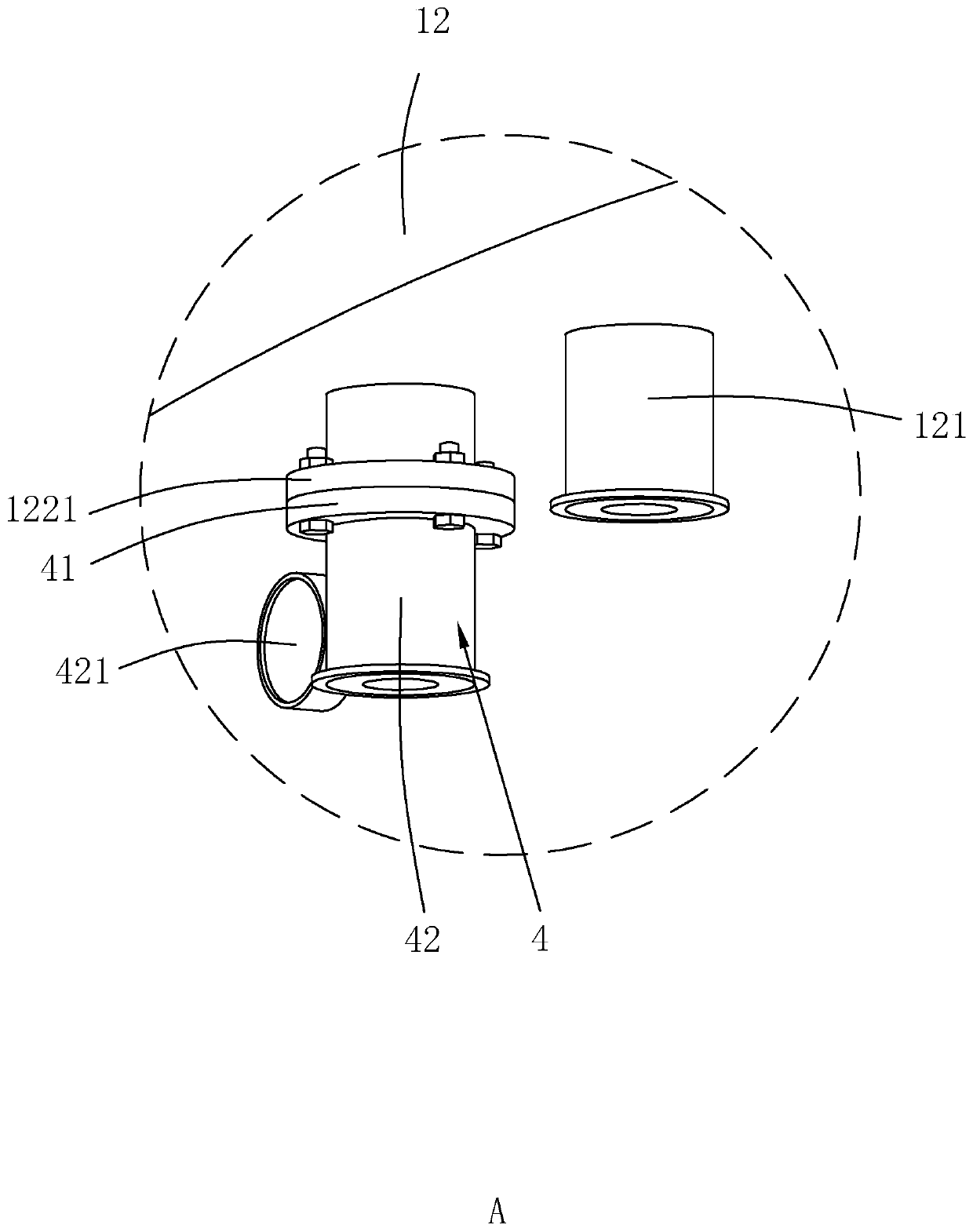

[0052] refer to figure 2 and image 3 , a fixed flange 1221 is arranged on the inner side of the belt mold grouting por...

Embodiment 2

[0064] A method for constructing the second lining of a tunnel, using the lining trolley in Embodiment 1, comprising the following steps:

[0065] S1. Install the second-lined steel bars, chisel and rinse the concrete on the surface of the joint between the inverted arch and the second-lined, bind the main reinforcement and stirrups of the second-lined, and when binding the toe of the wall and the steel bars of the inverted arch, encrypt the main reinforcement and place them on the near side Encrypt the protective layer pad on one side of the mold 11, and adjust the steel bar to a circular arc that can match the connection position of the bottom of the lining trolley and the inverted arch steel bar through the entire row of guy wires;

[0066] S2. The lining trolley is in place, the lining trolley walks to the position of the vertical mold, and is positioned by the total station to make the lining trolley accurately in place, the hydraulic jacking cylinder lifts the side formwo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com