Explosion-proof joint surface gap online detection method and device based on machine vision

A machine vision and joint surface technology, applied in measuring devices, optical devices, instruments, etc., can solve problems such as high cost, applicable conditions, harsh working environment requirements, and unsuitable for daily inspection of explosion-proof gaps in coal mines. Binding of angles and distances, the effect of precise measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

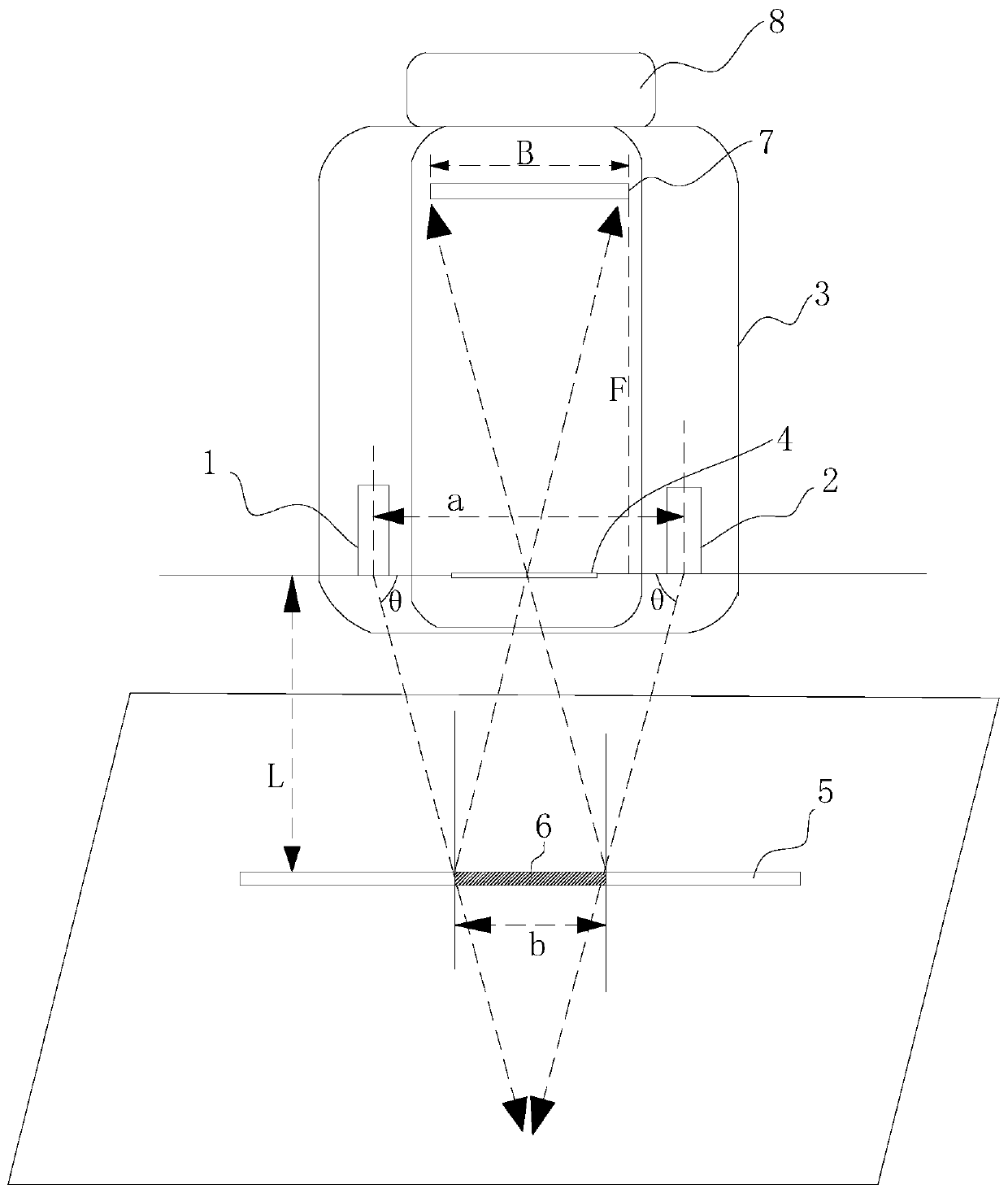

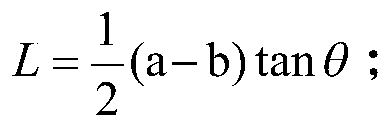

[0029] This embodiment provides a machine vision-based online detection method for flameproof joint surface gaps, such as figure 1 As shown, it is mainly used to detect the width of the gap to be measured, including the following steps:

[0030] S1. Set two sets of line light sources 1 and 2 above the gap 5 to be measured, each set of line light sources 1 and 2 are located on the same horizontal line, and the line beams emitted by each set of line light sources 1 and 2 have the same Angle θ; a convex lens 4 is arranged between the two groups of line light sources 1 and 2, and the center of the convex lens 4 is located on the same horizontal line as each group of line light sources 1 and 2; a CCD imaging module is arranged above the convex lens 4; Adjust the focal length F of the convex lens 4, so that the imaging of the gap 5 to be measured (in this embodiment, the gap between the flameproof joint surface of the explosion-proof electrical equipment) is in a clear state;

[00...

Embodiment 2

[0042] This embodiment provides a device for the method described in Embodiment 1, such as figure 1 As shown, it includes a line light source 1 and 2, a convex lens 4, a CCD imaging module, an image analysis calculation module and a power supply 8, and the power supply 8 supplies power for the line light source, the CCD imaging module and the image analysis calculation module;

[0043] The line light sources include two groups, each group of line light sources 1 and 2 are located on the same horizontal line, and the line beams emitted by each group of line light sources 1 and 2 have the same angle with the horizontal line; The gap to be measured emits a linear beam, which is on the same plane as the gap to be measured and intersects;

[0044] The convex lens 4 is arranged between the two groups of line light sources 1 and 2, and its center is on the same horizontal line as the line light source, so that the interval 6 between the incident points of the two groups of line light...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com