Method for evaluating influence of pile position deviation uncertainty on anti-seepage effect based on finite elements

An uncertain and finite element technology, applied in the field of finite element-based evaluation of the influence of pile position deviation uncertainty on anti-seepage effect, can solve problems such as pile position deviation, engineering economic loss, water-stop quality accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

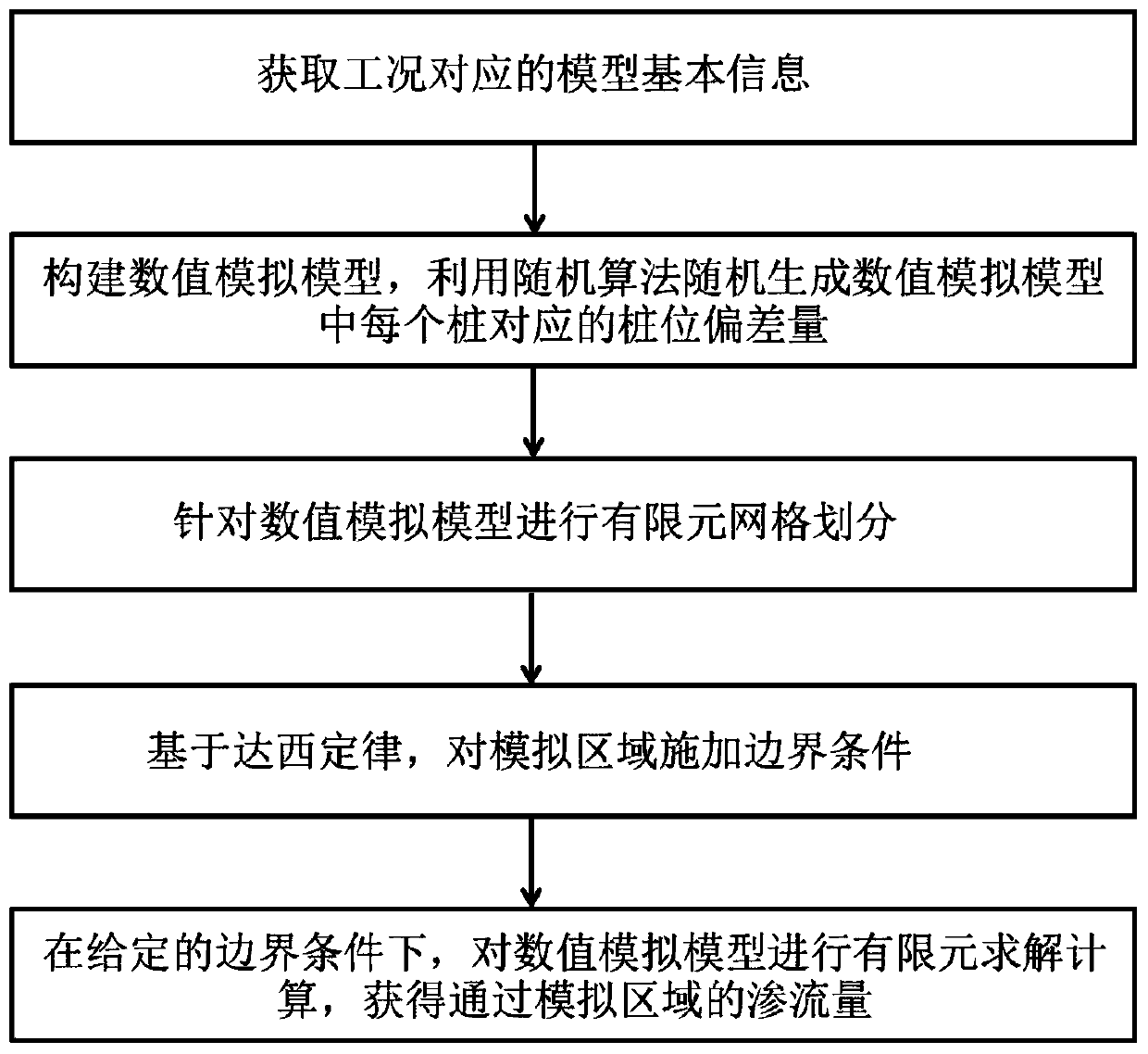

[0049] The finite element-based method for assessing the impact of the uncertainty of the pile position deviation on the anti-seepage effect provided by Embodiment 1, such as figure 1 As shown, it mainly includes the following steps:

[0050] Step 1. Obtain the basic information of the model corresponding to the working condition.

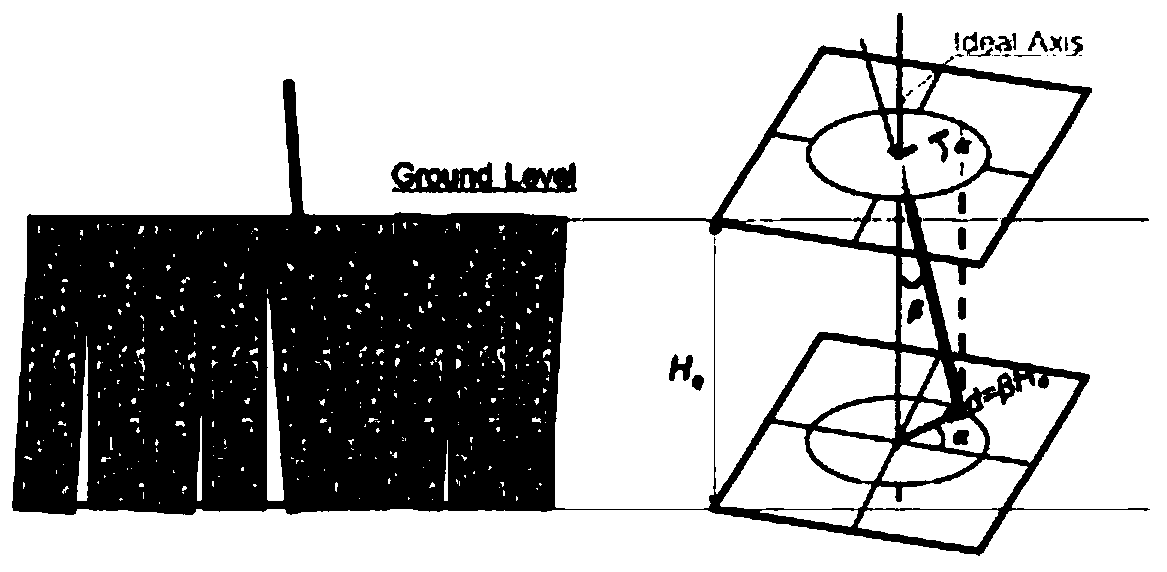

[0051]Wherein, one key information in the basic information of the model is the maximum pile position deviation angle. In addition, the basic information of the model also includes: permeability coefficient information, geometric dimension information, the permeability coefficient information includes the seepage coefficient of the pile, the seepage coefficient of the land in the simulation area; the geometric dimension information includes the number of piles, the size of the pile information. The size information of the piles includes pile diameters, pile lengths, and overlapping lengths between piles.

[0052] Step 2. Construct a numerical si...

Embodiment 2

[0117] Example 2 Using the finite element-based evaluation method for the impact of the uncertainty of pile position deviation on the anti-seepage effect proposed in Example 1, evaluate the anti-seepage effect of the pile position deviation on the condition that the maximum pile position deviation angle is 0.5%. The impact of the effect.

[0118] Embodiment 2 first obtains the basic information of the model corresponding to the working condition, including the following two aspects:

[0119] 1.1 Determine the input parameters (permeability coefficient).

[0120] Simulate a specific actual working condition, where the seepage coefficient of the pile is 1×10 -9 m / s, the permeability coefficient of the soil in the simulation area is 1×10 -5 m / s.

[0121] 1.2 Determine the geometric size.

[0122] Eight piles are intercepted in the simulation area, each pile has a diameter of 1.6m, the length of the pile is 20m, and the overlapping length between piles is 300mm. The maximum p...

Embodiment 3

[0126] Example 3 Using the finite element-based method for evaluating the influence of pile position deviation uncertainty on the anti-seepage effect proposed in Example 1, evaluate the anti-seepage effect of the pile position deviation under the working condition that the maximum pile position deviation angle is 1.0%. The impact of the effect.

[0127] Embodiment 3 first obtains the basic information of the model corresponding to the working condition, including the following two aspects:

[0128] (1) Determine the model information.

[0129] 1.1 Determine the input parameters (permeability coefficient).

[0130] Simulate a specific actual working condition, where the seepage coefficient of the pile is 1×10 -9 m / s, the permeability coefficient of the soil in the simulation area is 1×10 -5 m / s.

[0131] 1.2 Determine the geometric size.

[0132] Eight piles are intercepted in the simulation area, each pile has a diameter of 1.6m, the length of the pile is 20m, and the ove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com