Compact high-average-power matching load

A technology for matching load and average power, applied in waveguide-type devices, electrical components, circuits, etc., can solve problems such as increased manufacturing costs, difficult processing of absorbers, and easy breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

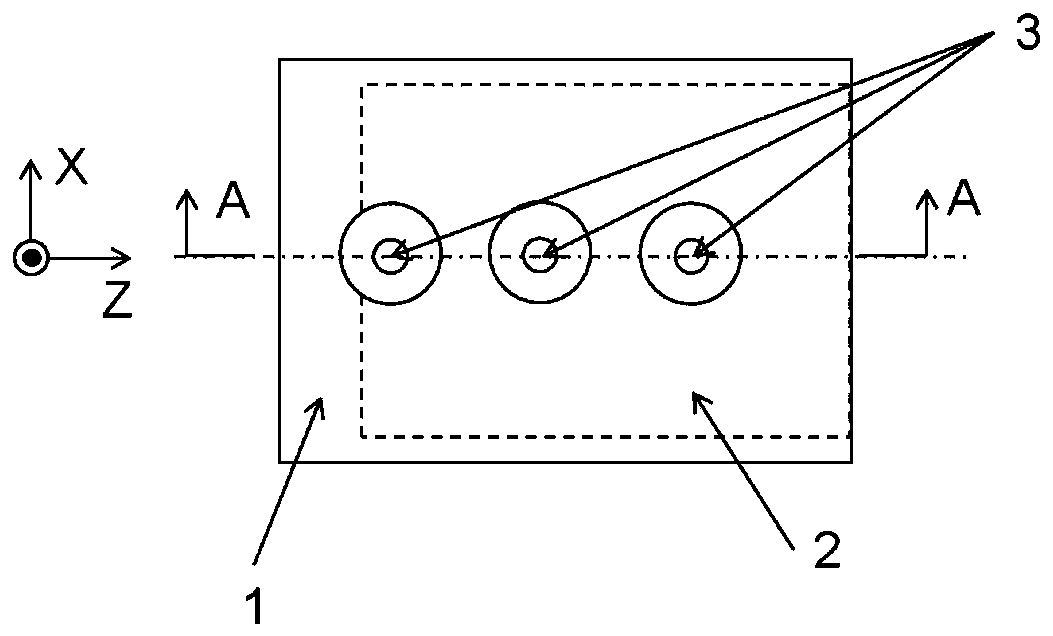

[0030] Such as figure 1 and 2 shown.

[0031] A compact large average power matching load, including a section of transmission line 1 whose axis is short-circuited at the right end along the Z direction, an absorber 2 located in the transmission line 1, and three tuning screws 3; the tuning screws 3 are connected from the The outside of the transmission line 1 protrudes into the inside of the transmission line 1 , and the depth of the tuning screw 3 inside the transmission line can be adjusted from the outside of the transmission line 1 .

[0032] The transmission line 1 is a rectangular waveguide, and its broad side is along the X direction.

[0033] The shape of the absorber 2 is a cone, and the minimum width and minimum height of the cone are both greater than 1 / 50 of the working wavelength of the compact high-power matching load.

[0034] The number of the absorber 2 is one, which is arranged at the bottom of the transmission line 1 and contacts the inner wall of the tr...

Embodiment 2

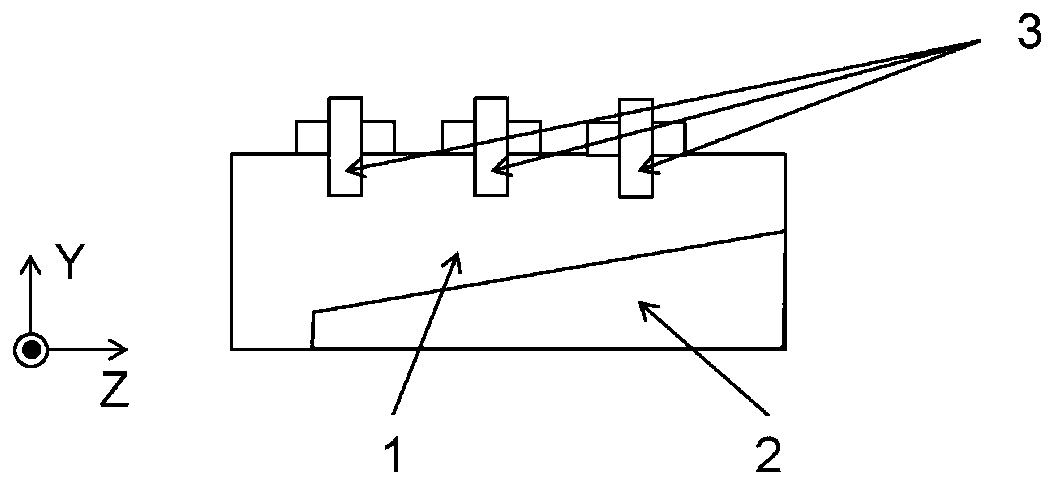

[0038] Such as image 3 and 4 shown.

[0039] Compared with Example 1, the only difference is that the shape of the absorber 2 is rectangular. Rectangular absorbers are easier to process than conical absorbers, which can significantly reduce processing costs.

Embodiment 3

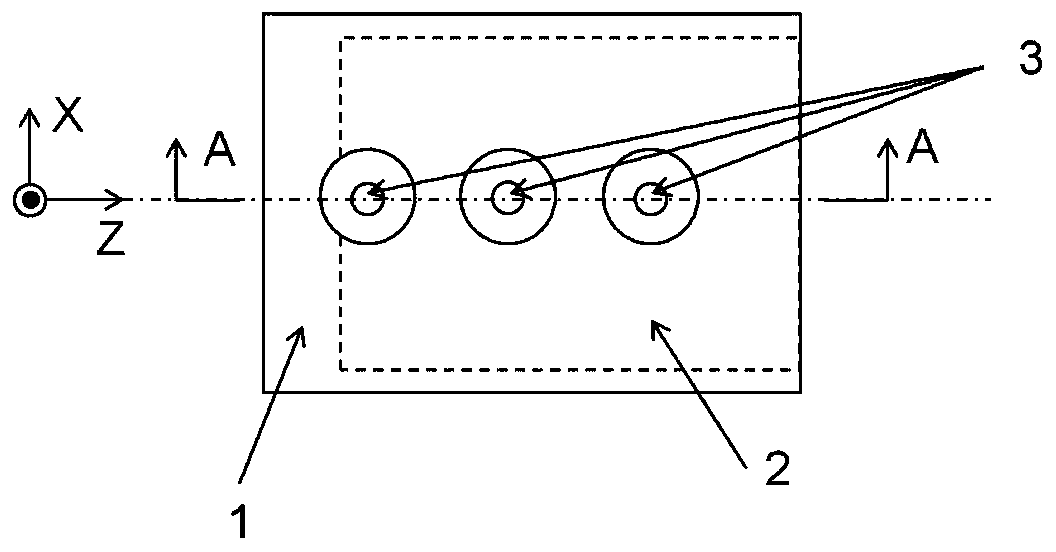

[0041] Such as Figure 5 and 6 shown.

[0042] Compared with Example 1, the only difference is that the number of the absorbers 2 is two, which are respectively arranged on the two side walls of the transmission line 1, and are respectively connected to the inner wall of the transmission line 1 in the X direction and - X-direction contact. The number of the tuning screws 3 is 6, which are arranged on the transmission line 1 along the Z direction. Three of the tuning screws 3 are arranged at the top of the transmission line 1 , and the other three of the tuning screws 3 are arranged at the bottom of the transmission line 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com