A rotary garlic splitting device

A rotary and garlic technology, applied in the field of rotary garlic splitting device, can solve the problems of reducing the service life of fixed fine needles, inconvenient disassembly, damage to fixed fine needles, etc., achieving good rubbing effect, stable splitting work, and improved product quality. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

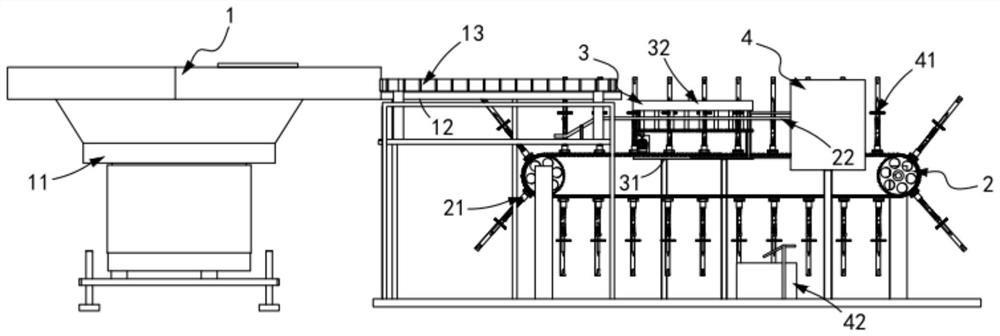

[0058] Such as figure 1 Shown, a kind of rotary garlic splitting device comprises:

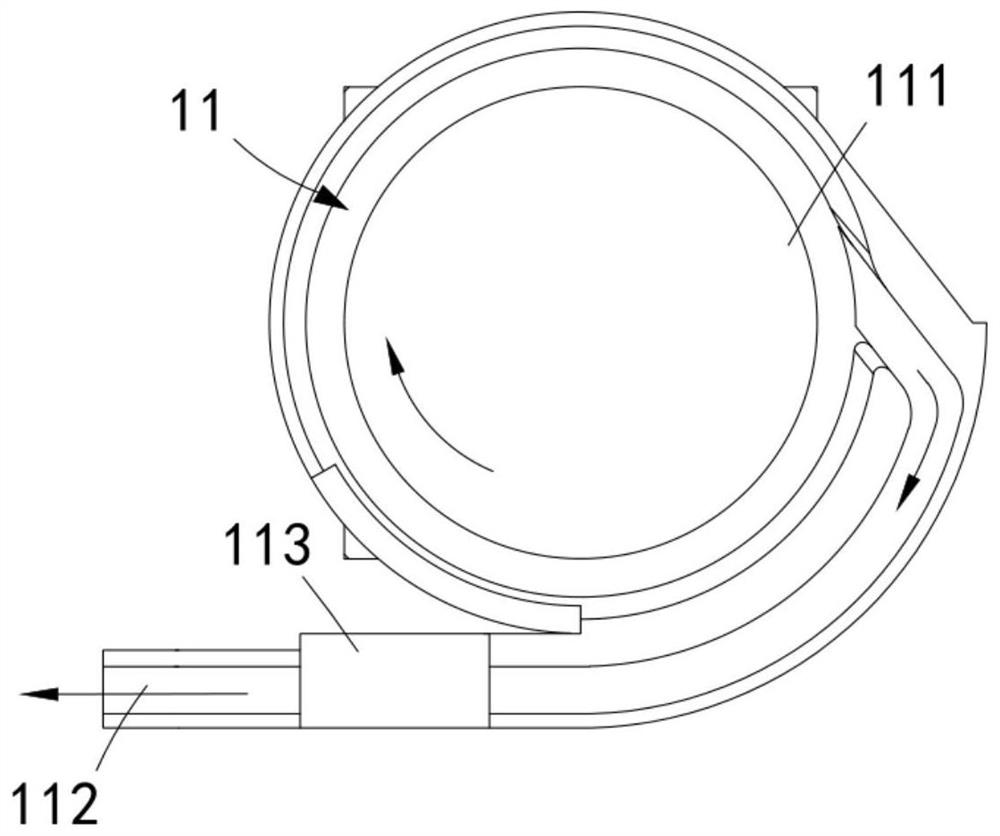

[0059] Sorting input mechanism 1, said sorting input mechanism 1 includes a sorting feeding assembly 11, a support platform 12 arranged at the output end of said sorting feeding assembly 11, two groups of conveying assemblies 13 arranged on both sides of said supporting platform 12, The center of the output end of the support table 12 is provided with a through slot 121 along its length direction;

[0060] The garlic conduction mechanism 2, the garlic conduction mechanism 2 includes a transmission assembly 21 arranged below the support table 12 and a first guide assembly 22 installed on the sorting input mechanism 1 and guiding the transmission assembly 21;

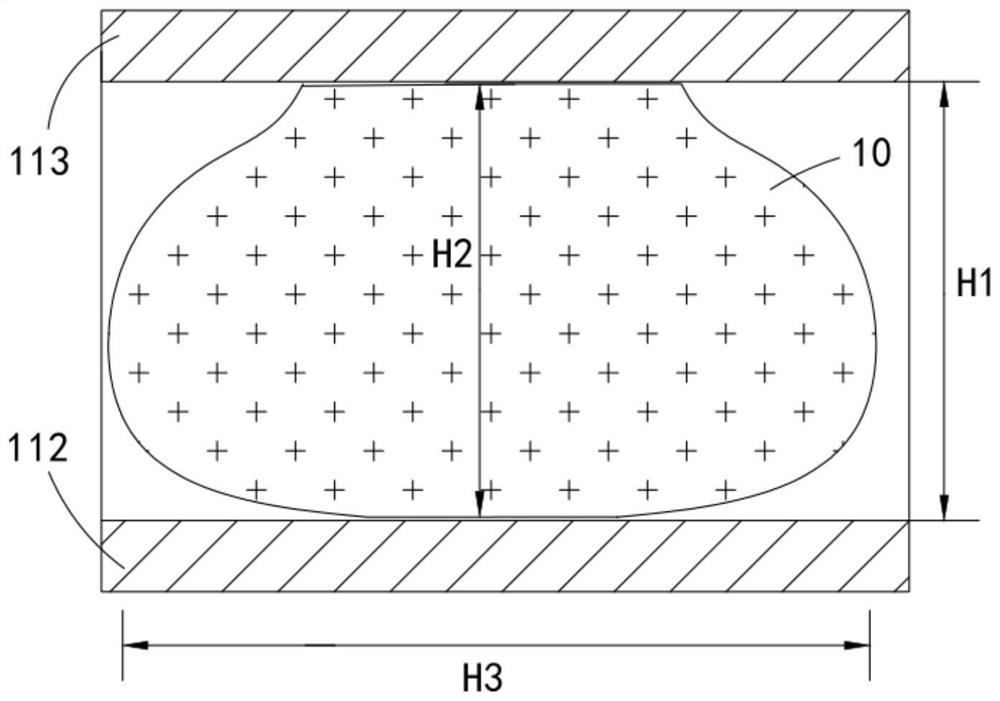

[0061] Kneading mechanism 3, described kneading mechanism 3 comprises support frame 31 and two groups of kneading assemblies 32 that are symmetrically arranged on said support frame 31, forms kneading space 30 between two groups of knead...

Embodiment 2

[0091] Such as Figure 17 , Figure 18 , Figure 19 and Figure 20 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0092] further, such as Figure 17 , Figure 18 , Figure 19 and Figure 20 As shown, the garlic root shedding assembly 42 includes a second guide assembly 421 that is installed on the conveying assembly 21 and cooperates with the second guide assembly 421 that drives the garlic root 20 on the conveying assembly 21 to fall off automatically, and is installed on the conveying assembly 21 and is located at the Describe the garlic root collection box 422 below the second guide assembly 421;

[0093] The second guide assembly 421 includes two sets of pushing rails 423 sym...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com