Thin film composite film with metal-organic framework as functional layer, preparation method thereof, and preparation method of metal-organic framework

A metal-organic framework and composite membrane technology, applied in the field of filtration membranes, can solve the problems of difficulty in preparing large areas, high costs, cumbersome steps, etc., and achieve high industrial application prospects, easy large-scale preparation, and good repeatability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] Preparation of ZIF-L thin film composite membrane:

[0086] 1) Dissolve 2-methylimidazole (0.692g, 8.4mmol) in 10ml of a 5% polyethyleneimine (PEI) aqueous solution, and dissolve zinc nitrate hexahydrate (1.188g, 4.1mmol) in 6ml of After mixing the two solutions in ionized water, the solution turned milky white, stirred at room temperature for 10 min, then added 35 ml of absolute ethanol, and stirred for another 2 h.

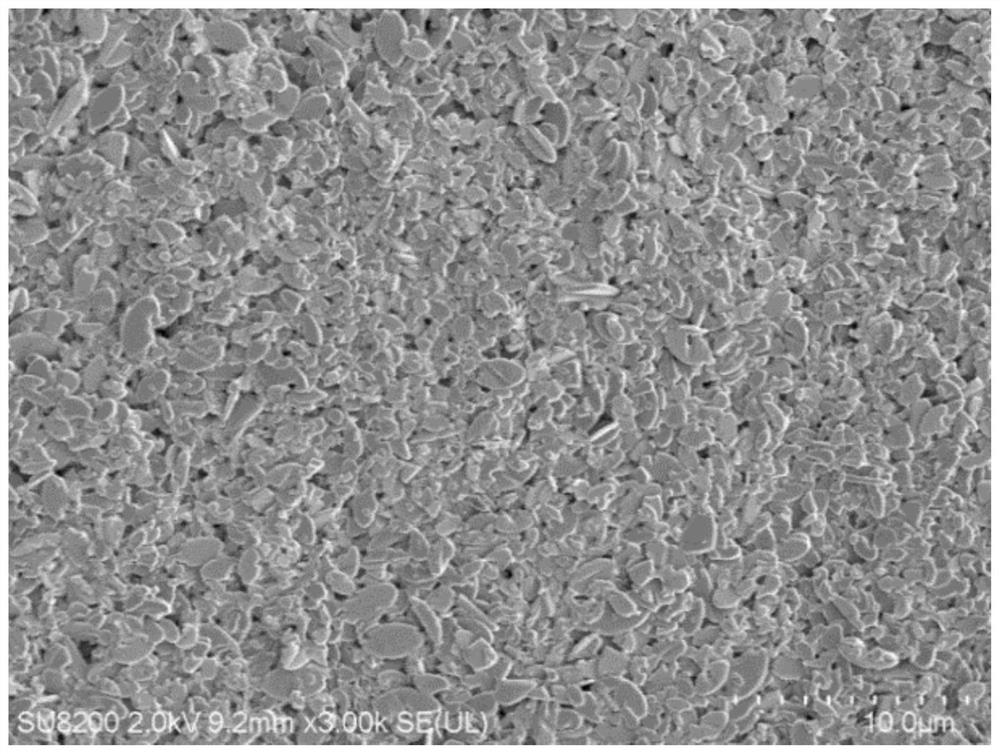

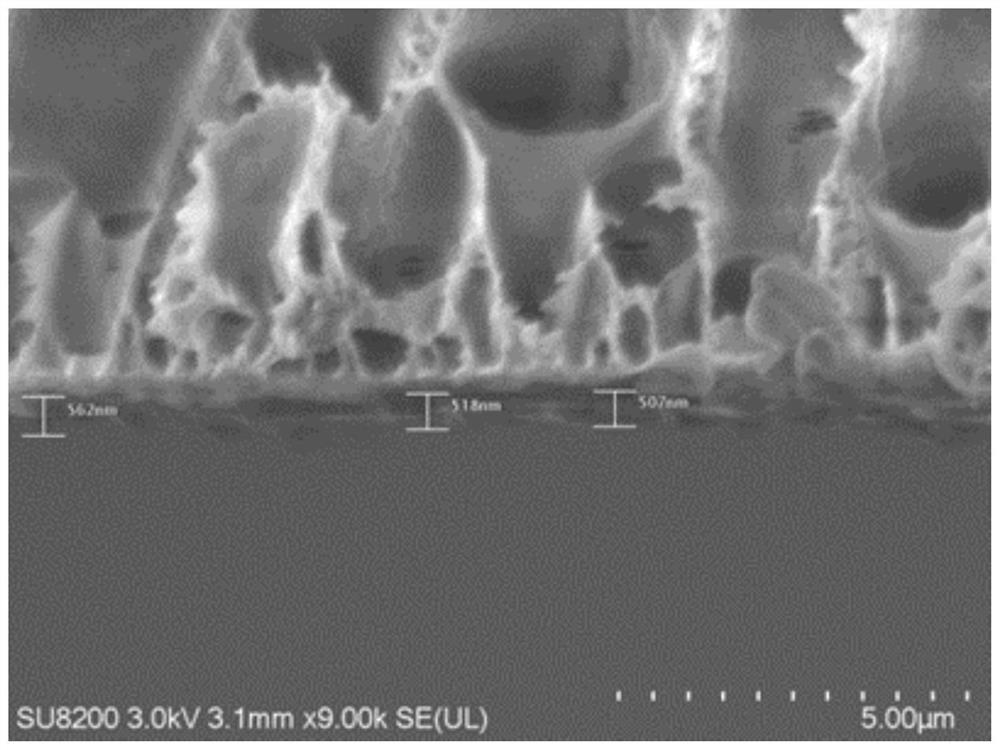

[0087] 2) The obtained solution was sprayed on the polyacrylonitrile substrate with an area of 4.5cm*4.5cm and 10 times using a spraying machine, and the spraying conditions were: the heating temperature of the heating plate where the substrate was located was 60°C, the flow rate was 0.2ml / min, and the needle was separated from the substrate. 5cm, ambient temperature room temperature. A film with a uniform thickness of ZIF-L on the surface (named as ZIF-L film) was obtained from figure 1 The scanning electron microscope image of the ZIF-L film shows t...

Embodiment 2

[0097] Similar to the method of Example 1, the metal organic framework used is UIO-66-NH 2 .

[0098] 1) 25mg of UIO-66-NH 2 After being added to 5 ml of 1% diethylenetriamine aqueous solution by mass fraction to obtain a mixed liquid, 30 ml of methanol was added to obtain a dispersion liquid.

[0099] 2) Spray the obtained dispersion on the polyacrylonitrile substrate with a spraying area of 4.5cm*4.5cm for 25 times using a spraying machine. The conditions used for spraying are: the heating temperature of the heating plate where the substrate is located is 50°C, and the flow rate is 0.2ml / min , the needle is 6cm away from the substrate, and the ambient temperature is room temperature. Get a surface with a layer of UIO-66-NH 2 The film (named UIO-66-NH 2 film), from Figure 10 The SEM image can be found that UIO-66-NH 2 There are a lot of particles on the surface of the membrane, which is granular UIO-66-NH 2 .

[0100] 3) Add UIO-66-NH 2 The membrane is glued to th...

Embodiment 3

[0103] Similar to the method of Example 1, the metal organic framework used is MIL-101-NH 2

[0104] 1) 45mg of MIL-101-NH 2 After being added to 5 ml of 1% triethylenetetramine solution by mass fraction to obtain a mixed solution, 40 ml of ethanol was added to obtain a dispersion.

[0105] 2) Use a sprayer to spray the obtained dispersion on the polyacrylonitrile substrate with an area of 4.5cm*4.5cm30 times. The conditions used for spraying are: the heating temperature of the heating plate where the substrate is located is 70°C, the flow rate is 0.15ml / min, the needle 4cm away from the substrate, the ambient temperature is room temperature. Get a sheet with a layer of MIL-101-NH on the surface 2 The film (named MIL-101-NH 2 film), from Figure 13 The SEM image can be found that MIL-101-NH 2 There are a lot of particles on the surface of the membrane, which is granular MIL-101-NH 2 .

[0106] 3) MIL-101-NH 2 The membrane is glued to the receiver roller of the elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com