Space scalable type mechanical arm based on 4D printing and expanding and contracting method thereof

A robotic arm and space technology, applied in manipulators, program-controlled manipulators, claw arms, etc., can solve problems such as limiting the performance of printable shape memory polymers, and achieve the effect of promoting development and expanding application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

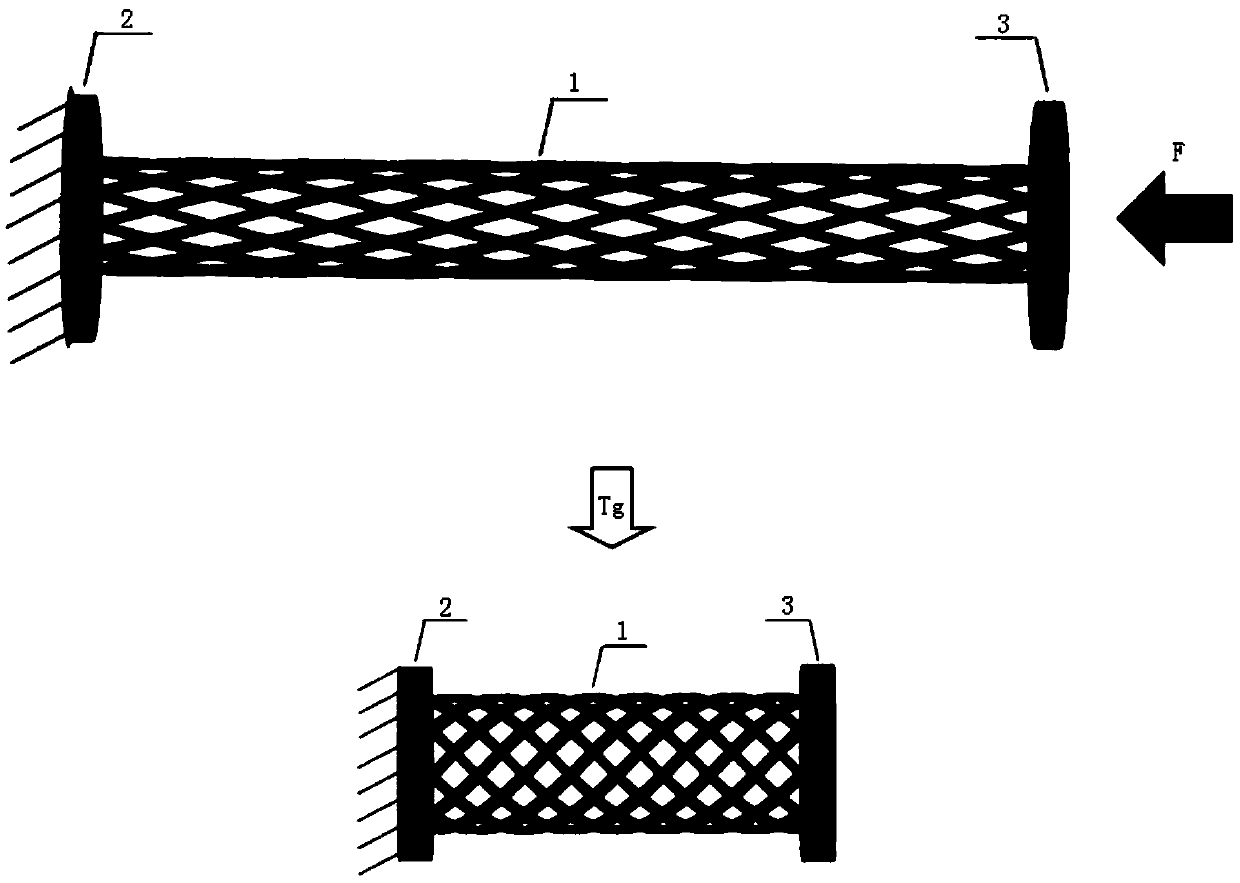

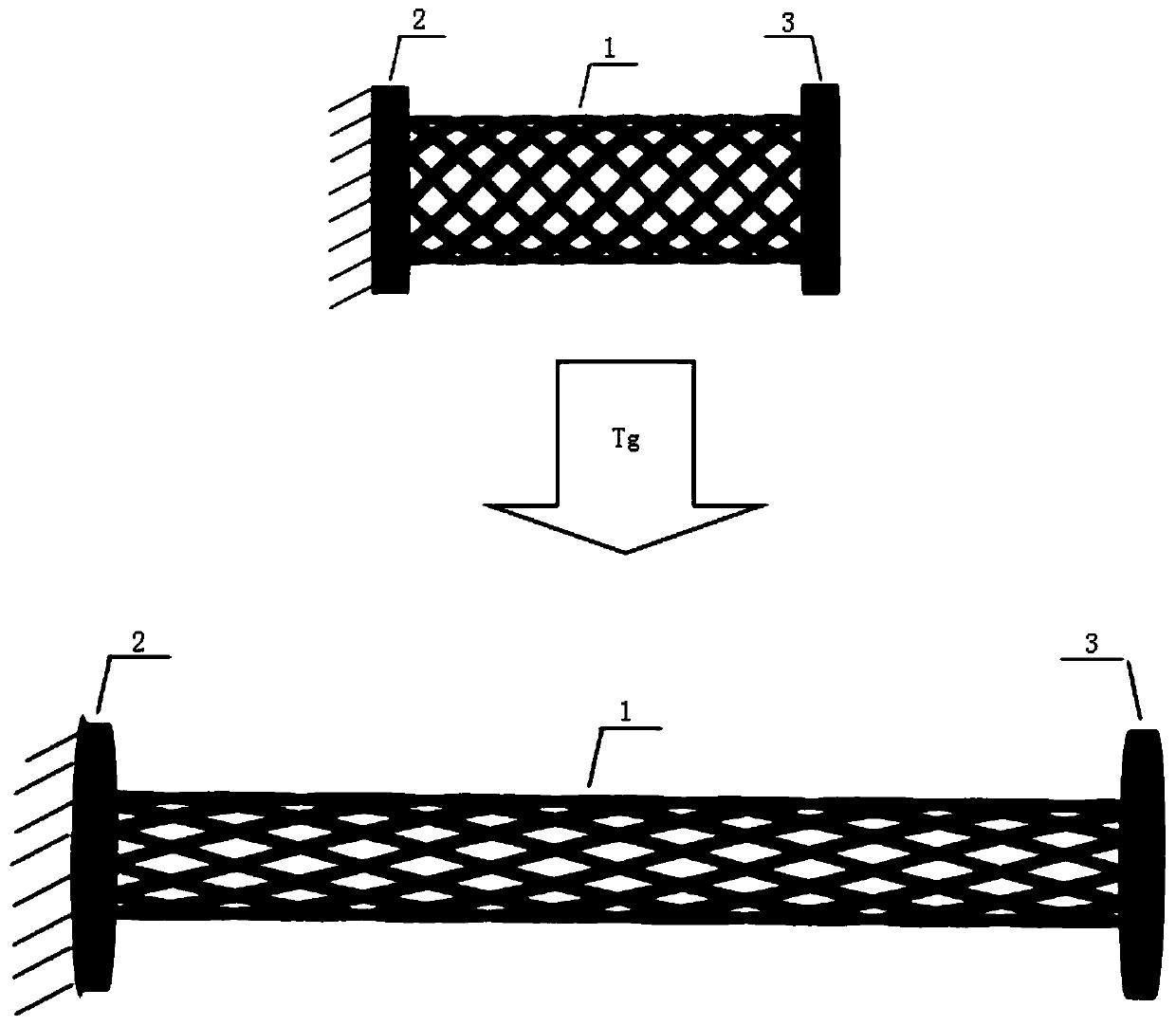

[0022] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

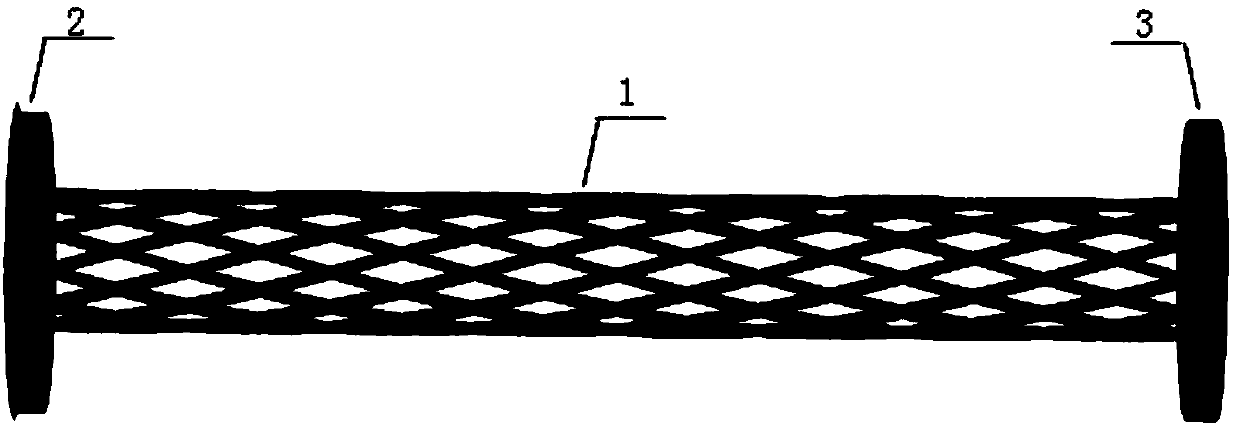

[0023] see Figure 1-3 Describe this embodiment, a spatially scalable robotic arm based on 4D printing, which includes a hollow columnar structure 1, a first press plate 2 and a second press plate 3, the hollow columnar structure 1 is formed by 4D printing technology, and the hollow columnar structure The material of the structure 1 is shape memory polymer, the wall surface of the hollow columnar structure 1 is distributed in a network shape, and the two ends of the hollow columnar structure 1 are respectively connected with the first pressing plate 2 and the second pressing plate 3 .

[0024] The shape memory polymer described in the present invention is a polylactic acid material, which has thermoplasticity and shape memory effect, can undergo active deformation under thermal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com