Dust suppressing and dropping device and method for dumping plough

It is a technology for soil removal and dust removal. It is applied in the directions of transportation, packaging, loading/unloading, etc. It can solve the problems of enlarged design selection, difficulty in raising dust by directional dust removal, and difficulty in condensation of water flow and dust, so as to save manufacturing costs and operations. Energy consumption, ensure reliability and accuracy, and increase the effect of dust emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

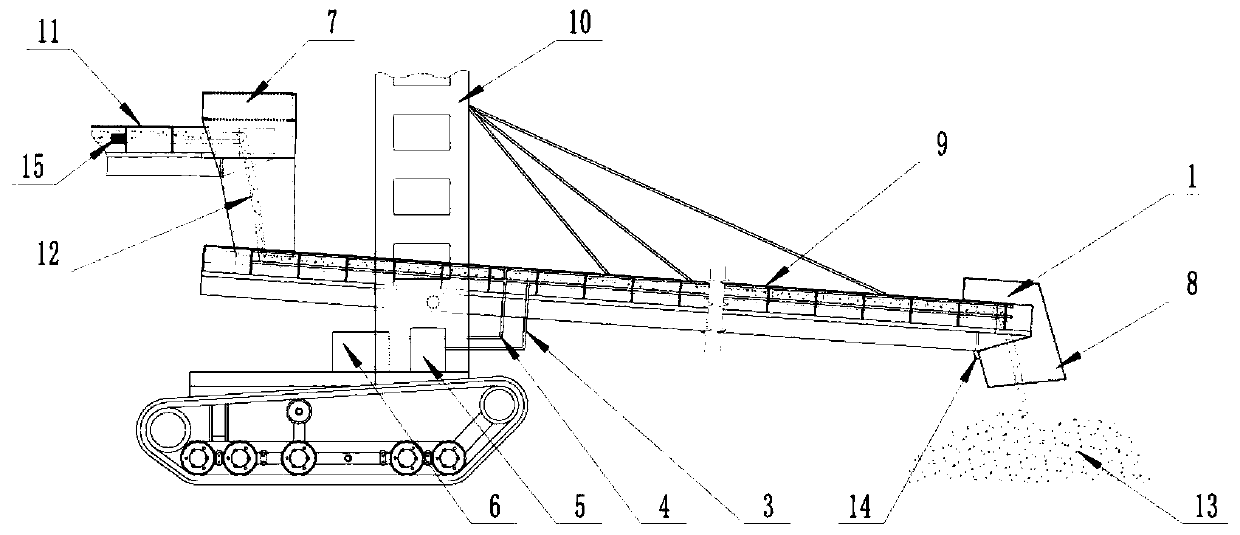

[0035] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

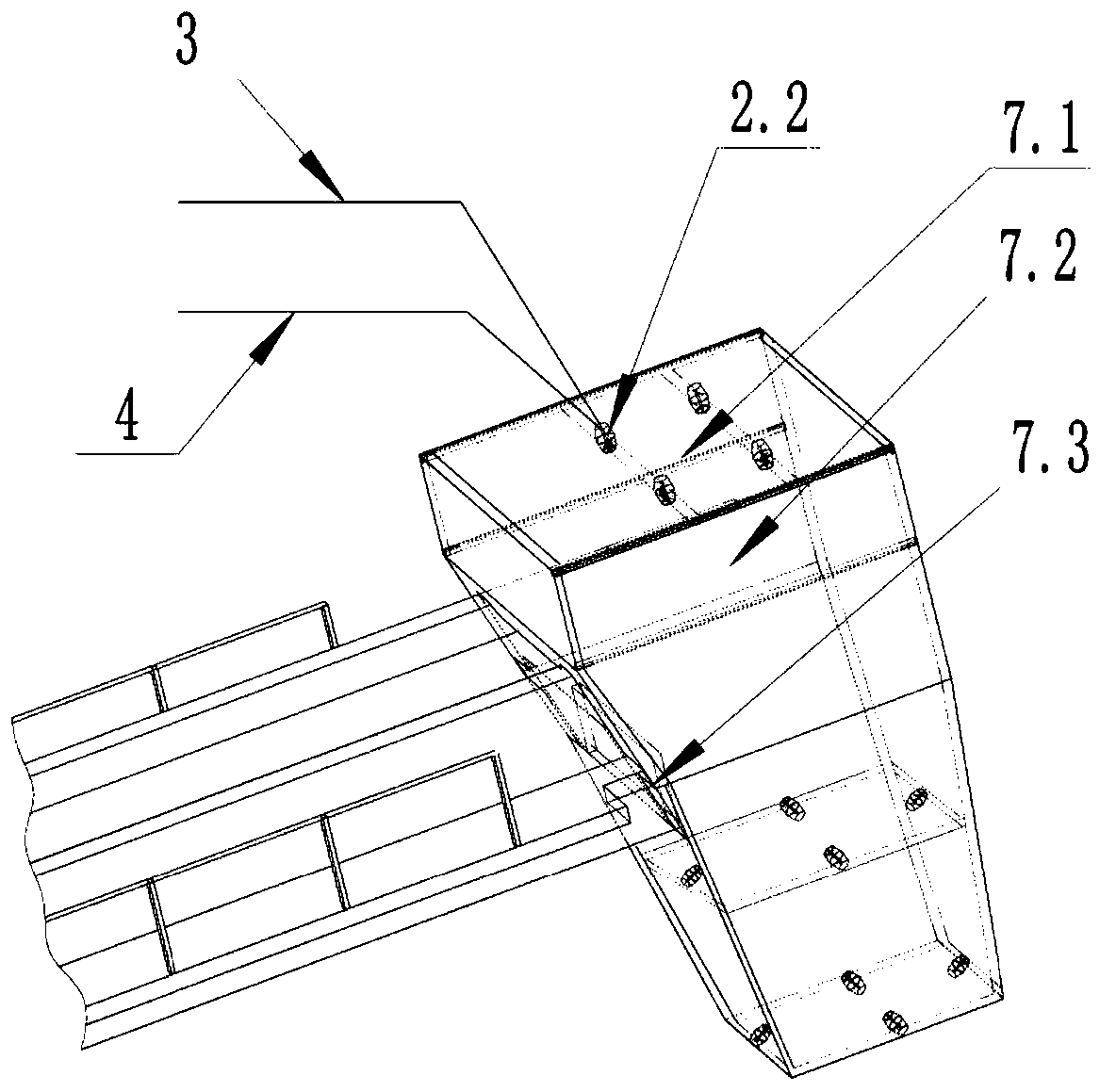

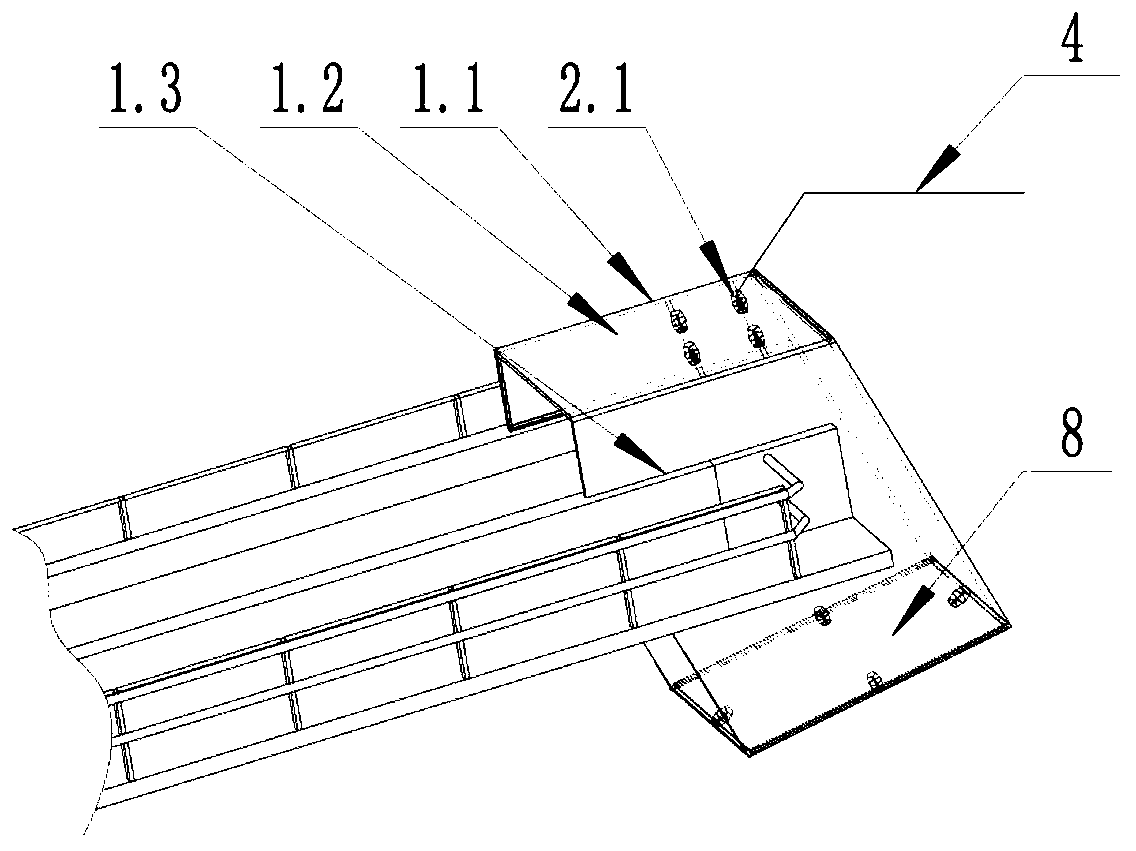

[0036] The invention discloses a dust suppression and dust reduction device for a soil dumper, which comprises a spray device and a dust suppression cover, and the spray device is a single-fluid spray device and / or a double-fluid spray device. Described single-fluid spraying device comprises the water pump 6, water pipe 4, single-fluid nozzle 2.1 that are connected successively; The water pipe 4 is connected, the air compressor 5 is connected with the air pipe 3, and the water pipe 4 and the air pipe 3 are respectively connected with the two-fluid nozzle 2.2. The dust suppression cover is a semi-enclosed structure with a circular, square, trapezoidal or irregular cross-se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com