Carrier tape buffering machine with compact structure

A technology with compact structure and buffer machine, which is applied in the field of buffer machine, can solve the problems of easy failure, complex buffer structure, and large space occupation, and achieve the effect of not easy failure, simple and compact structure, and small space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

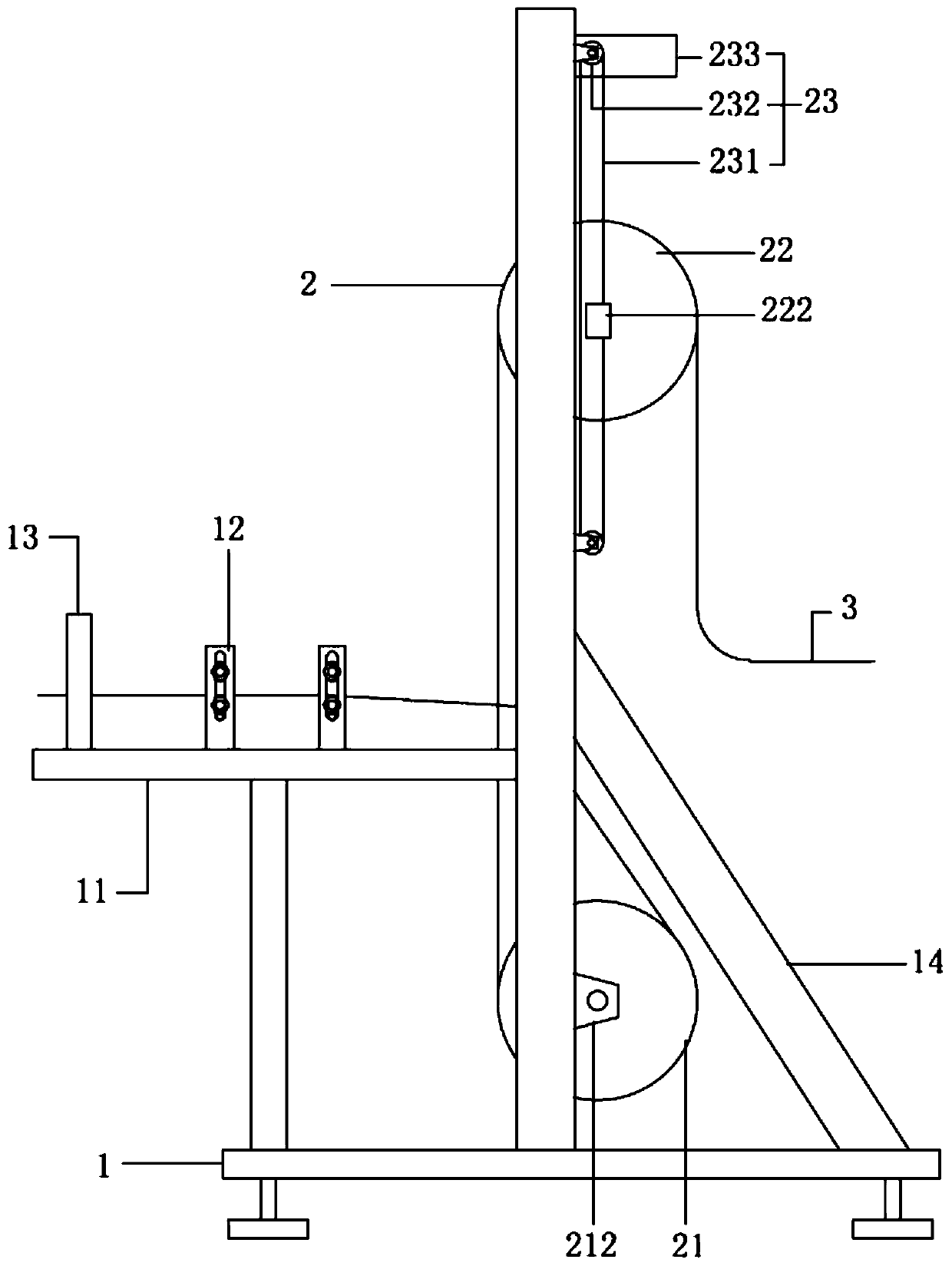

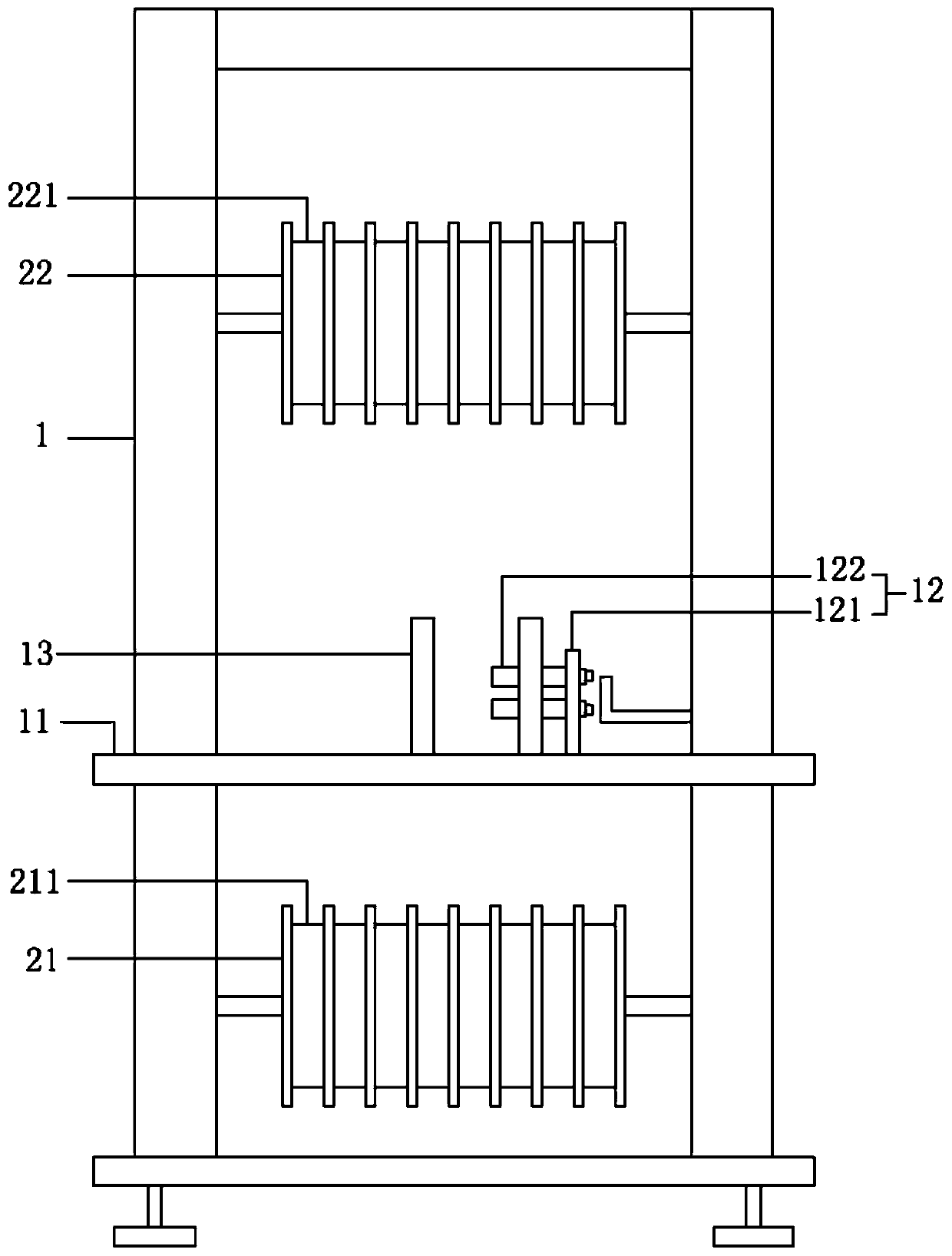

[0021] see Figure 1 to Figure 3 , the figure shows a compact tape buffer machine provided by Embodiment 1 of the present invention, including a frame 1, which is in an inverted "T" shape, and is provided with Arranged guide wheel mechanism 2, the guide wheel mechanism 2 includes a fixed guide wheel 21, a movable guide wheel 22 and a lifting mechanism 23, and the fixed guide wheel 21 is provided with a plurality of first rollers arranged along its own axial direction for winding the material tape 3. A groove 211, the first shaft seat 212 at both ends of the rotating shaft of the fixed guide wheel 21 is fixedly installed on the frame 1, and the movable guide wheel 22 is provided with a plurality of second shafts arranged along its own axial direction for winding the material tape 3. The groove 221 and the second shaft seat 222 at both ends of the rotating shaft of the movable guide wheel 22 are fixedly installed on the conveying chain 231 of the lifting mechanism 23 .

[0022]...

Embodiment 2

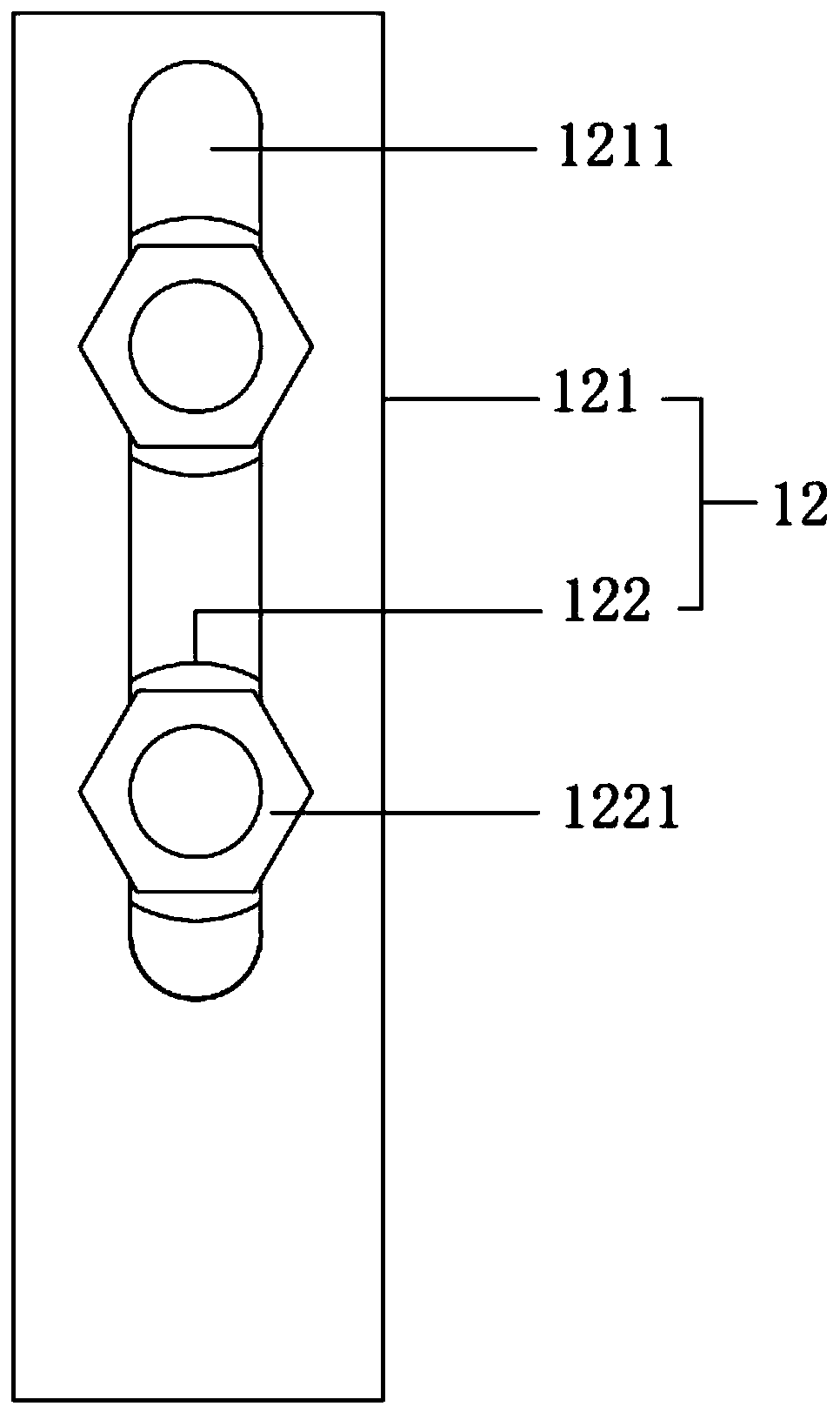

[0029] see Figure 1 to Figure 3 , the figure shows a compact strip buffer provided by Embodiment 2 of the present invention. On the basis of the above embodiment, this embodiment further makes the following technical solutions as improvements: the first guide column 13 and the second guide column 122 are smooth cylindrical structures.

[0030] Because the tape is relatively fragile, the first guide post and the second guide post are both cylindrical structures with smooth surfaces, which can avoid scratching and damaging the tape.

Embodiment 3

[0032] see Figure 1 to Figure 3 , the figure shows a compact tape buffer provided by Embodiment 3 of the present invention. On the basis of the above embodiments, this embodiment further makes the following technical solutions as improvements: the base 121 A bar-shaped hole 1211 is provided, and the bar-shaped hole 1211 is perpendicular to the working surface 11 , and the second guide post 122 is fixedly installed in the bar-shaped hole 1211 through a nut 1221 .

[0033] The two second guide posts can move up and down in the bar-shaped hole to adjust the height of the strip. A plurality of second guide column mechanisms are arranged in parallel in the conveying direction of the material belt. By adjusting the installation height of the second guide column and moving the movable guide wheel up and down, the tension force of the material belt can be adjusted to avoid the collapse of the material belt. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com