Piling device and method for driving piling material

A technology of piling device and tensioning device, which is applied to sheet pile walls, striking tools, lightweight impact tools, etc., can solve the problems of complicated installation and load affecting the stability of equipment structure, so as to increase the overall life and reduce the risk of overall inclination. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

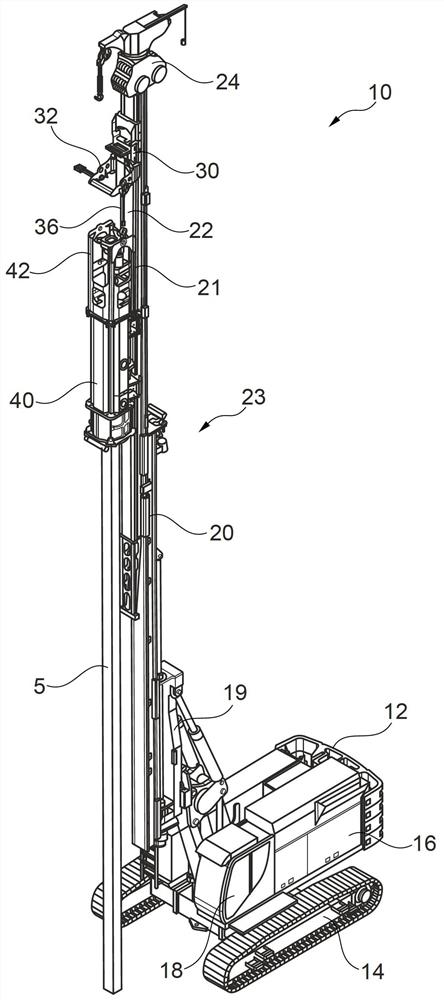

[0035] pass figure 1 The example in shows a piling device 10 according to the invention having a vehicle 12 and an upper carriage 16 rotatably supported thereon with an operating platform 18, the vehicle 12 having a crawler-type running gear The chassis 14. A mast 23 in the form of a telescoping guide is attached to the upper bracket 16 in a substantially vertical manner by means of a fixed guide element 20 via a generally known adjustment mechanism 19 . The adjustment mechanism 19 allows a pivotal movement of the mast 23 starting in the vertical direction and a displacement movement of the mast 23 in the longitudinal direction of the upper bracket as well as in the vertical direction. On the fixed link element 20 , a movable link element 21 is provided as a further component, which is guided in a displaceable and adjustable manner along the fixed link element 20 .

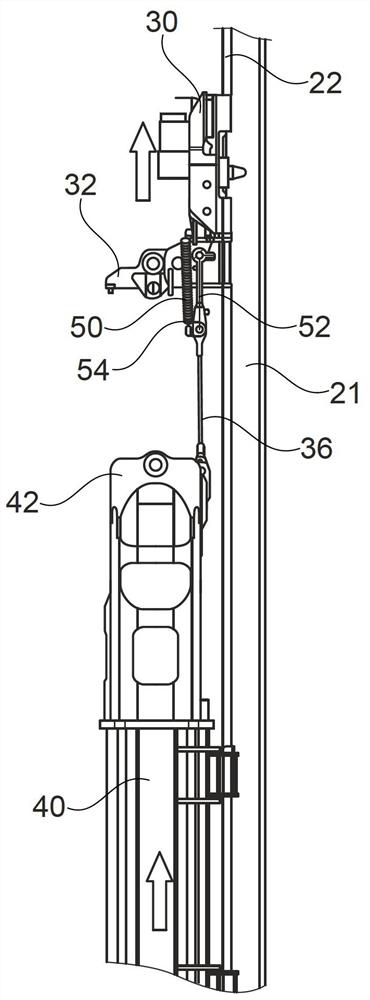

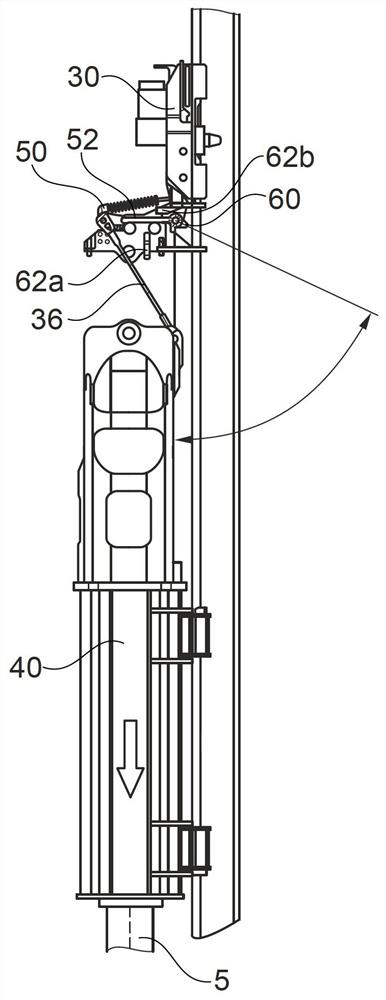

[0036] On the front side of the movable guide bar element 21 a linear guide 22 is designed, along which a bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com