Flexible glue dripping LED lens waterproof lamp strip and manufacturing method thereof

A technology of LED lens and manufacturing method, which is applied in the directions of gas/waterproof devices, lighting and heating equipment, semiconductor devices of light-emitting elements, etc., can solve the problems of poor waterproof sealing performance, limited irradiation distance, and inability to bend light strips. , to achieve the effect of improving waterproof sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the description of the drawings and specific embodiments.

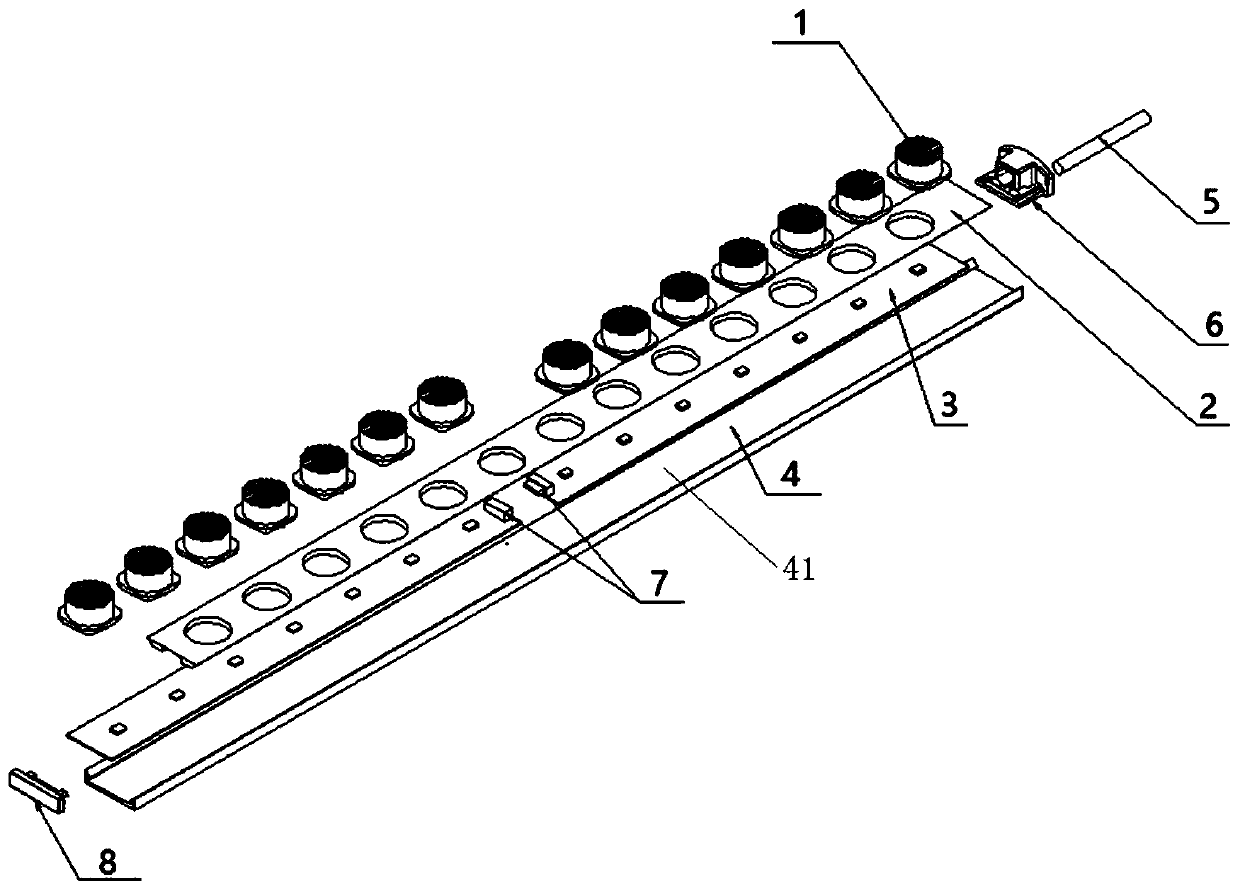

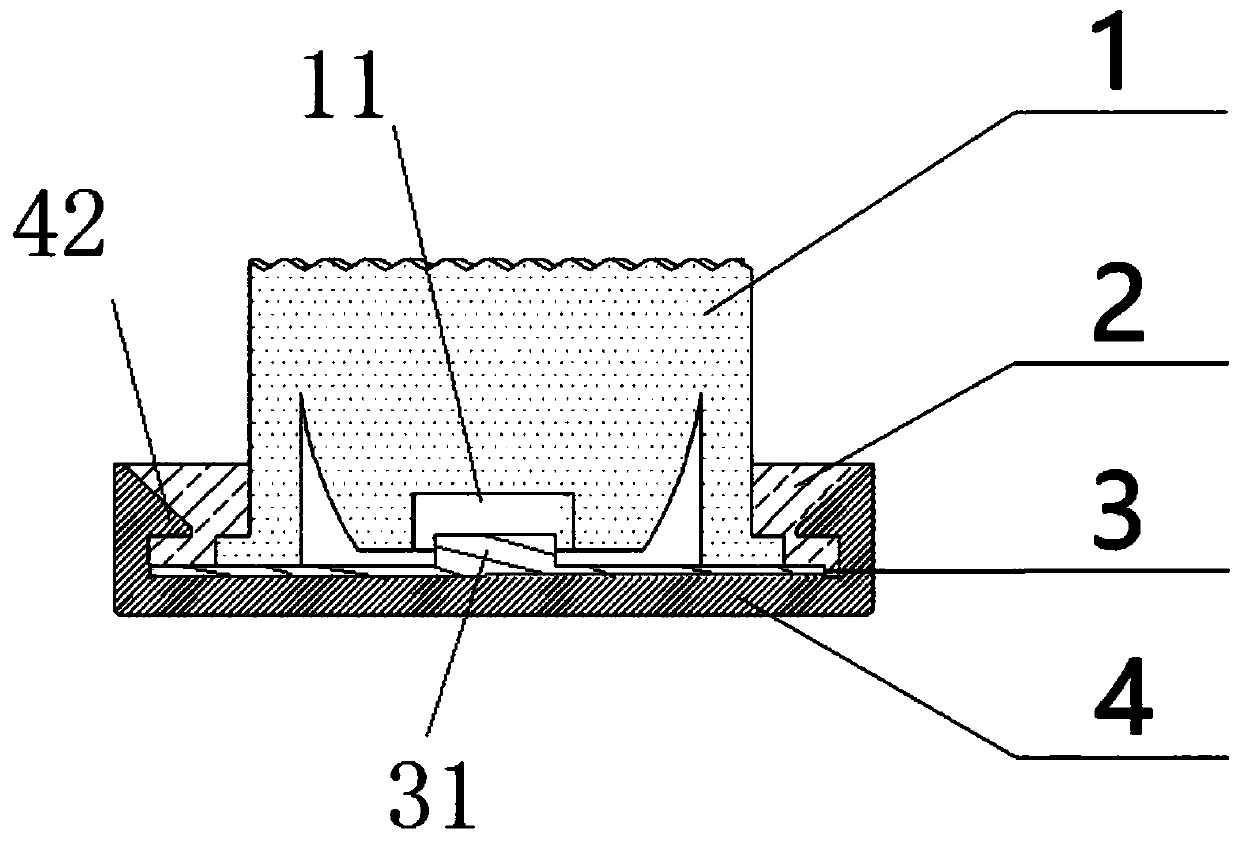

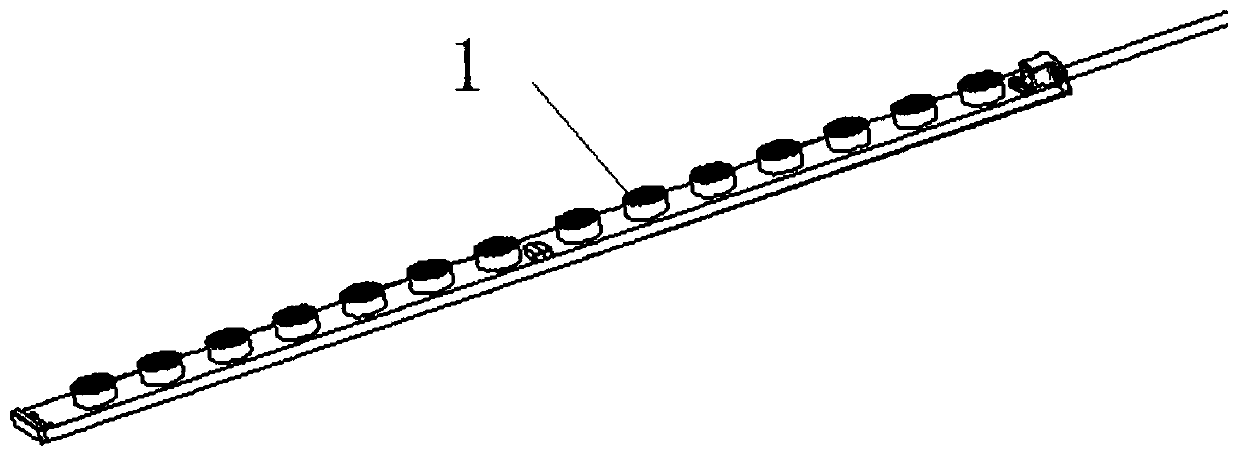

[0022] Such as Figure 1 to Figure 3 As shown, a flexible epoxy LED lens waterproof light strip, including a half sleeve 4, a flexible FPC lamp bead board 3 and a lens 1, the half sleeve 4 is provided with a mounting groove 41, and the flexible FPC lamp bead The board 3 is installed at the bottom of the installation groove 41 of the half sleeve 4, the bottom of the lens 1 is set on the flexible FPC lamp bead board 3, and the flexible FPC lamp bead board 3 is provided with lamp beads 31. The bottom of the lens 1 is provided with a lamp cavity 11, and the lamp bead 31 is located in the lamp cavity 11. The light emitting angle of the lamp bead 31 is restricted by the lens 1, which can meet the angle requirements for light. The inside wall of the installation groove 41 of the half sleeve 4, the flexible FPC lamp bead board 3, and the lens 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com