A liquid metal plasma color display device and its preparation method

A plasma and liquid metal technology, applied in cold cathode manufacturing, gas discharge electrode, electrode system manufacturing, etc., can solve the problems of high excitation voltage, high cost of material acquisition and packaging, inability to achieve curved surface or flexible display, etc. Simple, physical interface forms a variety of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

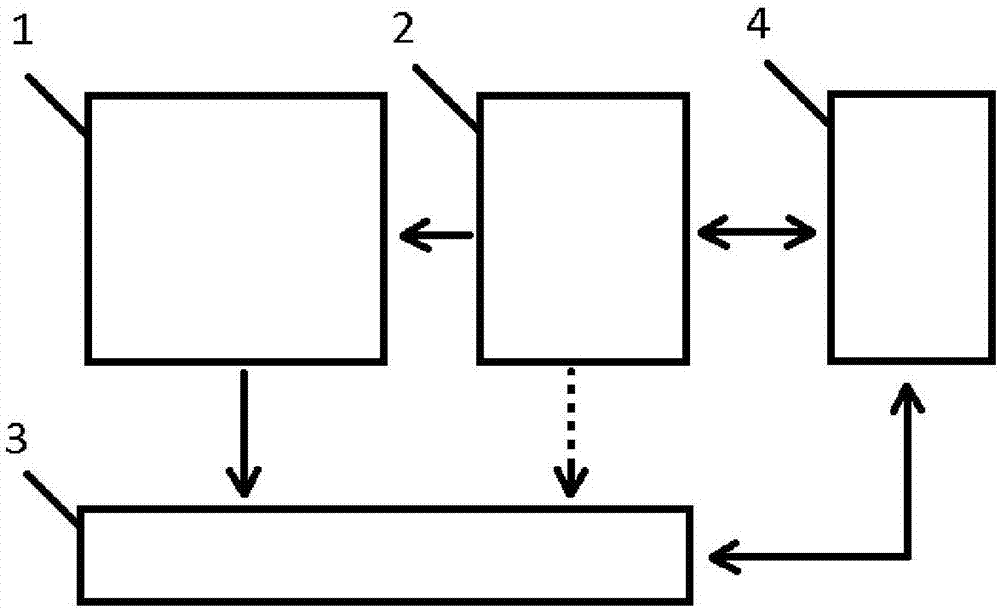

[0038] figure 1 The basic structure of a liquid metal plasma color display device is described.

[0039] Such as figure 1 As shown, the liquid metal-based plasma light-emitting unit 1 composed of room temperature liquid metal electrodes, plasma dielectric materials, and fluorescent materials is attached to the substrate and packaging material 3, and displays color graphics under the control of the electrode drive circuit 2. The electrodes The driving circuit 2 can be packaged on the substrate and the packaging material 3, or can be located outside it independently. At the same time, the liquid metal-based plasma light emitting unit 1 and the plasma electrode driving circuit can form a display array, and communicate with other liquid metal via the expansion interface 4. The metal plasma display devices are connected to realize display splicing.

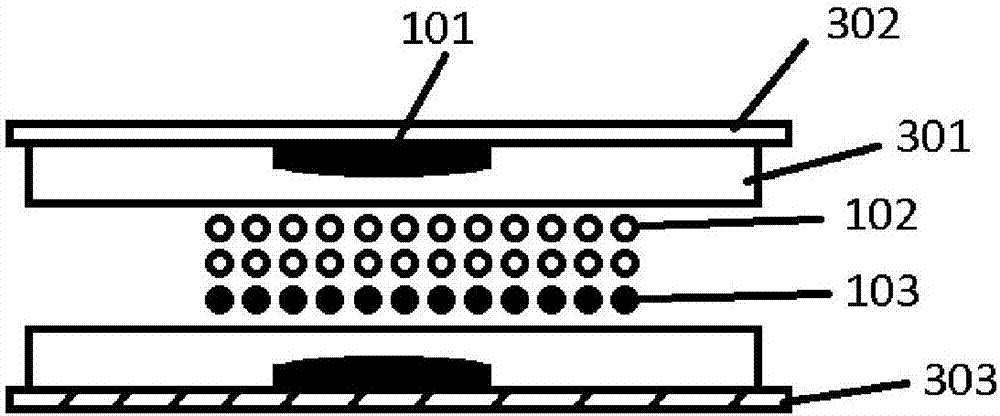

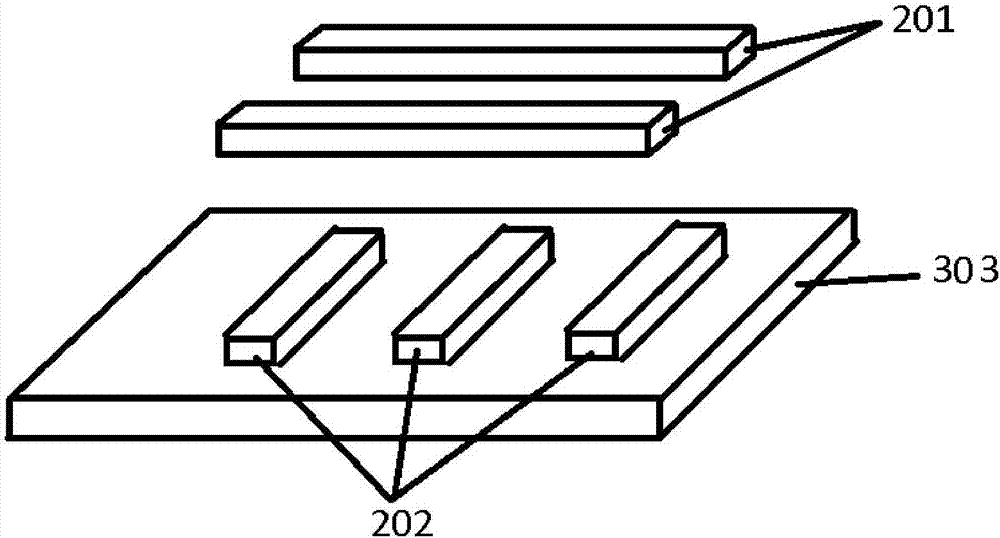

[0040] figure 2 The light-emitting unit structure of a liquid metal plasma color display device is described.

[0041] Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com