Construction and use method of an indoor air filtration and purification system

A technology for filtering and purifying indoor air, applied in air-conditioning systems, chemical instruments and methods, separation methods, etc., can solve the problem of lack of mechanical elimination of harmful germs, and achieve the effect of improving functions and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0092] A method for constructing and using an indoor air filtration and purification system, comprising the following steps:

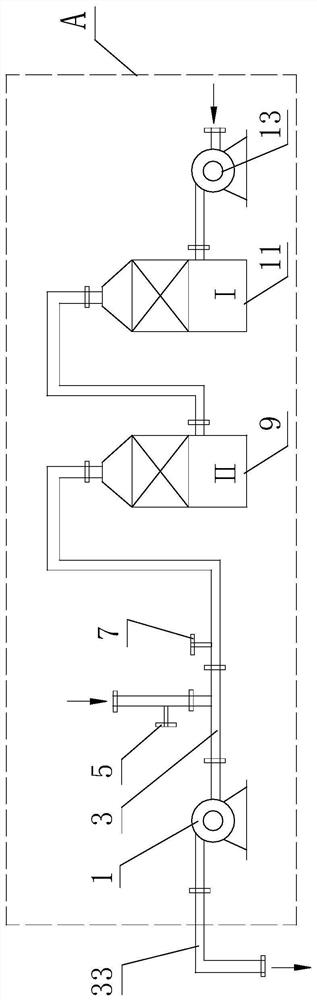

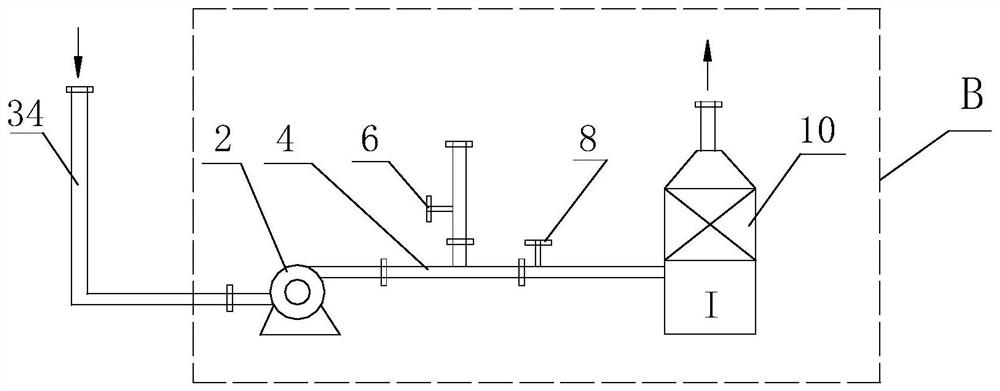

[0093] 1) Build an equipment collection platform for indoor air filtration and purification systems (such as figure 1 , figure 2 shown)

[0094] The indoor air filtration and purification system includes equipment collection platform A and equipment collection platform B, the main air supply duct drawn from equipment collection platform A, the main exhaust duct drawn from equipment collection platform B, and the main air supply duct derived from the main air supply pipeline Several air supply branch pipes with air outlets, and several exhaust air branch pipes with return air outlets derived from the main exhaust pipe are used for the fresh air (supply air), exhaust air (return air) and exhaust air of the indoor air filtration and purification system. The airflow in the wind system is filtered and purified, and the equipment collection platform for t...

Embodiment 2

[0109] On the basis of Example 1, step 1) in ③: the air outlets of each air supply branch pipe are installed at the upper part of the room and at the space point close to the "protection point" (healthy person), and the return air outlets of each exhaust air branch pipe are installed at The room is close to the floor and is close to the "suspicious point" (potential source of risk of transmitting germs), ensure that the air outlet and the return air are formed between the air outlet and the return air. , to ensure that the air flow formed in the room is first blown to the "protection point" in the upwind position, and then blows to the "suspect point" in the downwind position.

Embodiment 3

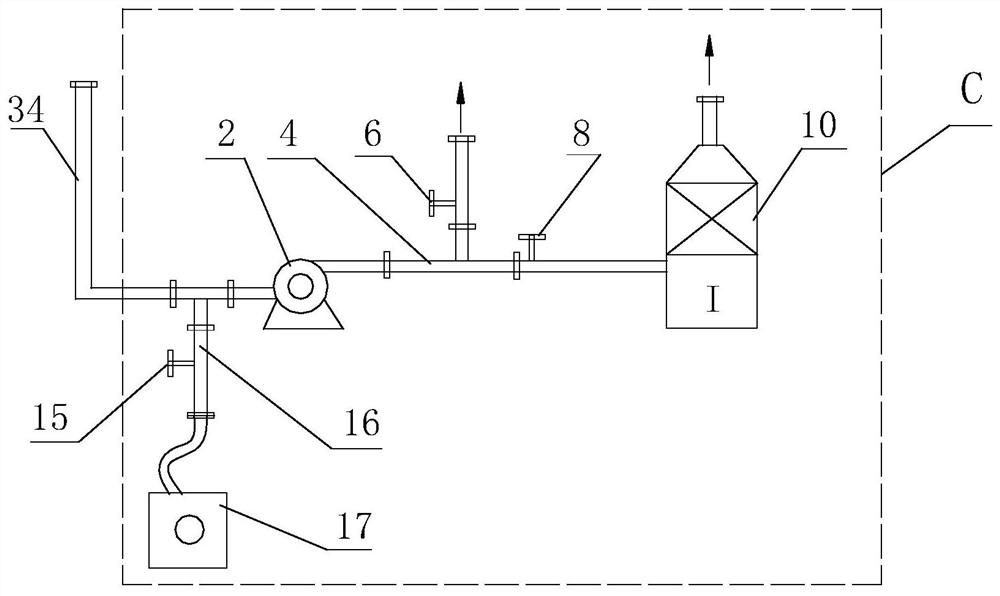

[0111] On the basis of embodiment 1, an ozone generator is connected in the main exhaust duct (i.e., the system return air duct) 34 of the air filtration and purification system to realize the prevention of adhesion of various germs to the inner wall of the main exhaust duct, the exhaust branch pipe, and the return air outlet. Mechanical disinfection operations (such as image 3 shown):

[0112] 1) The main exhaust pipe, exhaust branch pipe and the air inlet on it are all made of PVC plastic material instead of metal material;

[0113] 2) Set a ventilation branch pipe 16 with a pipeline control valve 15 at the air inlet end of the exhaust fan 2 in the equipment collection platform B, and the ventilation branch pipe 16 is connected with an ozone generator 17 to form a new equipment collection platform C:

[0114] 3) Perform a seamless functional transition between the operation of the indoor air filtration and purification system and the mechanical injection of ozone into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com